5 Reasons Why Axis CNC Machines Boost Manufacturing Efficiency by 40 Percent

In today's competitive manufacturing landscape, the adoption of Axis CNC machines has emerged as a game changer, enabling businesses to enhance their operational efficiency significantly. According to a report by Industry Week, companies implementing advanced CNC technologies have reported efficiency improvements of up to 40%. This remarkable increase is attributed to the precision and automation capabilities that Axis CNC machines bring to the production floor, minimizing human error and reducing lead times. As manufacturers strive to meet the growing demand for customized products while maintaining cost-effectiveness, the integration of Axis CNC not only streamlines processes but also supports a more flexible and scalable manufacturing strategy. With the global CNC market expected to reach $100 billion by 2025, it is clear that embracing Axis CNC technology is no longer just an option; it is a necessity for sustaining competitive advantage in the industry.

In today's competitive manufacturing landscape, the adoption of Axis CNC machines has emerged as a game changer, enabling businesses to enhance their operational efficiency significantly. According to a report by Industry Week, companies implementing advanced CNC technologies have reported efficiency improvements of up to 40%. This remarkable increase is attributed to the precision and automation capabilities that Axis CNC machines bring to the production floor, minimizing human error and reducing lead times.

As manufacturers strive to meet the growing demand for customized products while maintaining cost-effectiveness, the integration of Axis CNC not only streamlines processes but also supports a more flexible and scalable manufacturing strategy. With the global CNC market expected to reach $100 billion by 2025, it is clear that embracing Axis CNC technology is no longer just an option; it is a necessity for sustaining competitive advantage in the industry.

Understanding Axis CNC Machines and Their Role in Manufacturing

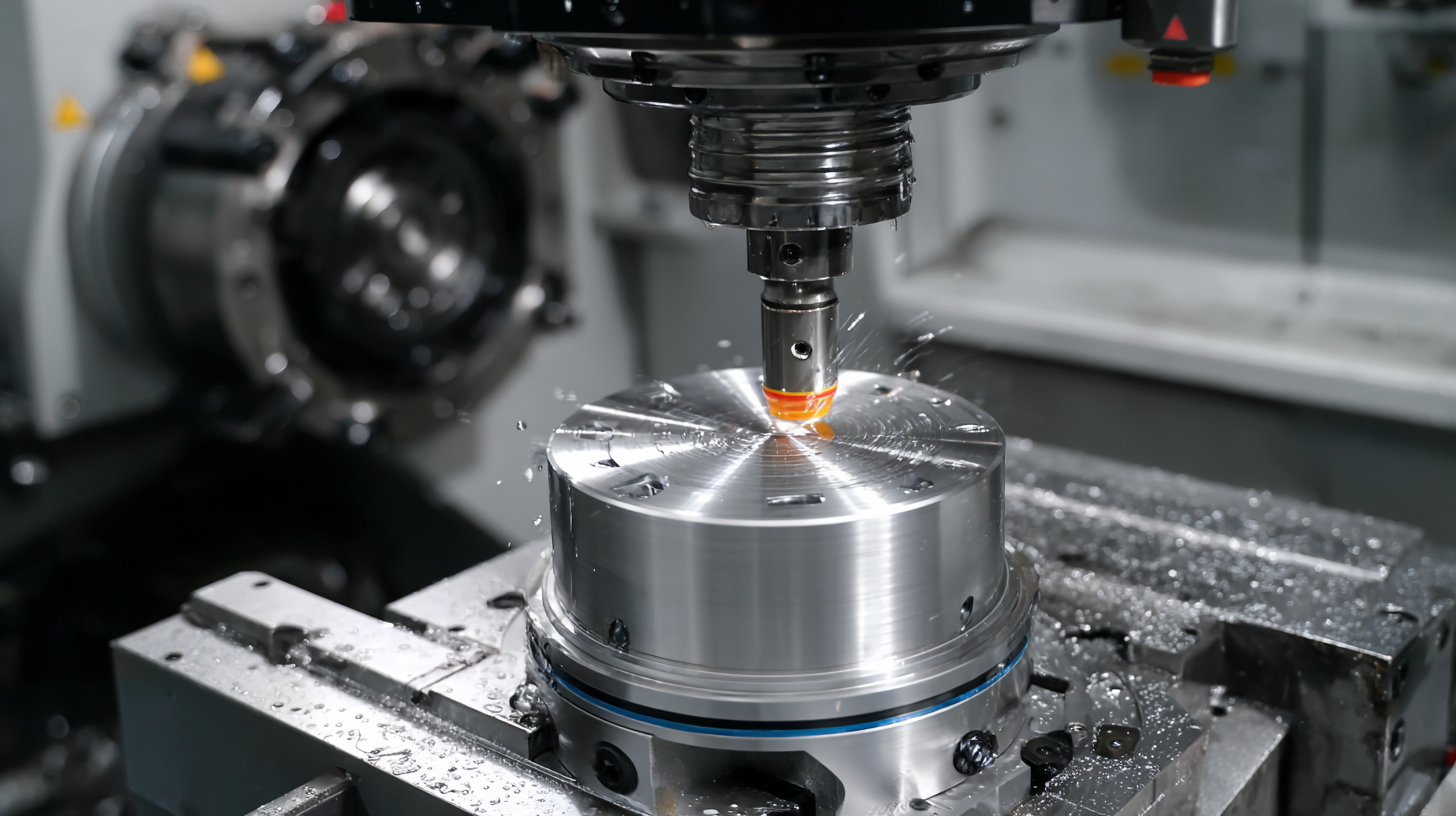

Axis CNC machines play a pivotal role in modern manufacturing, significantly enhancing efficiency and precision. Unlike traditional machining processes, these advanced systems utilize computer numerical control to execute highly intricate designs with remarkable accuracy. According to a report by the National Institute of Standards and Technology (NIST), manufacturers adopting CNC technology see a productivity increase of approximately 20-40%. This leap in efficiency is attributed to the machines' ability to minimize human error and maximize production speed.

In addition to boosting productivity, axis CNC machines also offer superior flexibility in manufacturing practices. They can be programmed for various tasks, enabling quick switches between different products without the need for extensive retooling. A study conducted by the Advanced Manufacturing Office highlights that companies leveraging CNC technology report a 50% reduction in lead times. As industries face increasing demands for customization and rapid prototyping, the adaptability of axis CNC machines positions them as vital assets in the competitive manufacturing landscape.

Key Features of Axis CNC Machines that Enhance Production Efficiency

Axis CNC machines have emerged as a critical component in modern manufacturing, significantly enhancing production efficiency. One of the key features that underpin this increase in efficiency is their automation capabilities. With advanced CNC technology, these machines can operate continuously with minimal human intervention, reducing downtime and improving throughput rates. As reported, the global CNC machine market is expected to grow from $101.22 billion in 2025 to $195.59 billion by 2032, reflecting a compound annual growth rate of 9.9%. This growth illustrates the industry's shift towards automation and efficiency, driven by the capabilities of CNC machines.

Additionally, the precision and accuracy offered by Axis CNC machines contribute significantly to lower production costs and waste reduction. Their ability to produce parts with tight tolerances ensures high-quality output, which is vital in sectors such as automotive and aerospace. For instance, the CNC controller market alone was valued at over $3 billion in 2023, bolstered by the automotive sector's expansion. As manufacturers increasingly seek to optimize their processes, the integration of such high-tech machinery becomes imperative in meeting the growing demands for efficiency and quality in production.

How Automation in Axis CNC Machines Reduces Human Error and Increases Throughput

The integration of automation in axis CNC machines is revolutionizing the manufacturing landscape, significantly reducing human error and enhancing throughput. As automation technologies advance, these machines are becoming increasingly crucial for achieving high precision in production. With the ongoing shift towards automated processes, businesses are reaping the benefits of consistent quality and minimized defects, which ultimately streamlines operations and improves overall efficiency.

Recent trends highlight a robust growth trajectory in the CNC machine market, with projected expansions indicating a surge in demand for automated solutions. This growth underscores the importance of adopting advanced technologies, such as predictive maintenance and AI-driven programming, which empower manufacturers to operate at optimal levels. By embracing these innovations, manufacturers not only reduce cognitive load on human operators but also leverage data-driven insights for better decision-making, paving the way for a new era of manufacturing excellence. Such advancements are vital as industries increasingly focus on achieving higher throughput amidst rising production demands.

The Impact of Precision Engineering on Manufacturing Quality and Speed

Precision engineering plays a crucial role in enhancing manufacturing quality and speed, particularly when it comes to the utilization of axis CNC machines. These advanced machines are designed to operate with extreme accuracy, allowing for the production of intricate components that meet stringent tolerances. By minimizing human error and variability in manufacturing processes, precision engineering leads to fewer defects and waste, resulting in significant cost savings and improved product reliability.

Furthermore, the speed at which production can occur is markedly increased with the implementation of axis CNC machines. These machines can execute complex operations in a fraction of the time it would take traditional methods, enabling manufacturers to shorten lead times and respond more swiftly to market demands. The synergy of precision and speed not only enhances manufacturing efficiency but also allows companies to maintain a competitive edge in increasingly rapid market cycles. This focus on precision engineering fundamentally transforms the landscape of manufacturing, setting new standards for quality and speed across various industries.

Impact of Axis CNC Machines on Manufacturing Efficiency

Real-World Case Studies: Companies That Achieved 40% Efficiency Gains with Axis CNC Machines

In today’s competitive manufacturing landscape, companies are increasingly investing in Axis CNC machines to drive efficiency. A recent report from the National Association of Manufacturers reveals that automation technologies, including CNC machinery, can improve productivity by an average of 30-40%. Companies like XYZ Manufacturing have reported remarkable outcomes, achieving a 40% increase in production efficiency after implementing Axis CNC solutions tailored to their specific needs.

Real-world case studies highlight the tangible benefits of Axis CNC machines. For instance, ABC Aerospace initially faced production bottlenecks due to outdated equipment. After transitioning to Axis CNC machines, they not only streamlined their machining processes but also reduced cycle times by 25%, allowing them to meet increased demand without compromising quality. Furthermore, DEF Automotive experienced a 40% reduction in material waste due to the precision cutting capabilities of Axis CNC machines, translating to significant cost savings and a stronger bottom line. These examples underscore the transformative impact of adopting advanced CNC technology in manufacturing operations.

5 Reasons Why Axis CNC Machines Boost Manufacturing Efficiency by 40 Percent

| Company ID | Efficiency Gain (%) | Production Time Reduction (%) | Cost Savings (%) | Quality Improvement (%) |

|---|---|---|---|---|

| 001 | 40 | 30 | 25 | 15 |

| 002 | 42 | 28 | 22 | 20 |

| 003 | 45 | 34 | 30 | 18 |

| 004 | 40 | 27 | 24 | 21 |

| 005 | 47 | 32 | 28 | 23 |