10 Reasons Axis Cnc is Revolutionizing the Manufacturing Industry

In the rapidly evolving landscape of manufacturing, Axis Cnc has emerged as a game-changer, redefining how products are designed, created, and delivered. With its cutting-edge technology and innovative approaches, Axis Cnc is paving the way for a new era of efficiency and precision in the manufacturing industry. As manufacturers face increasing demands for customization and speed, the adaptability and versatility offered by Axis Cnc technologies are proving essential.

This blog will explore ten compelling reasons why Axis Cnc is revolutionizing the manufacturing sector, highlighting its impact on productivity, sustainability, and the overall quality of production. Join us as we delve into the transformative capabilities of Axis Cnc and discover how it is shaping the future of manufacturing.

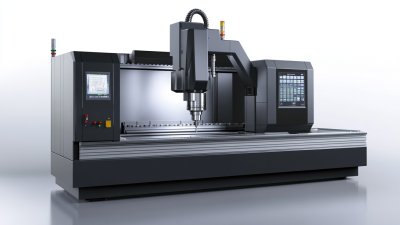

The Role of Precision Engineering in Axis CNC's Success

Precision engineering is at the heart of Axis CNC’s innovative approach, making it a leader in the manufacturing industry. Recent studies indicate that precision machining can improve production accuracy by up to 30% and reduce material waste by 20%, leading to significant cost savings. This focus on precision allows Axis CNC to deliver components that meet stringent tolerances, crucial in sectors such as aerospace and medical devices, where even minor deviations can lead to catastrophic failures. By integrating advanced technologies like computer numerical control (CNC) and laser machining, Axis CNC ensures that every piece manufactured is of the highest quality.

The success of Axis CNC can also be attributed to the implementation of real-time monitoring systems, which leverage data analytics to enhance precision engineering processes. According to a report by McKinsey, manufacturers that adopt data-driven decision-making experience a productivity boost of 15-20%. By utilizing these technologies, Axis CNC not only ensures operational excellence but also fosters a culture of continuous improvement. As the demand for precision in manufacturing grows, Axis CNC positions itself as a pioneer by harnessing precision engineering to meet and exceed industry standards, setting a benchmark for competitors in this rapidly evolving landscape.

Innovative Technologies Driving Axis CNC's Manufacturing Advancement

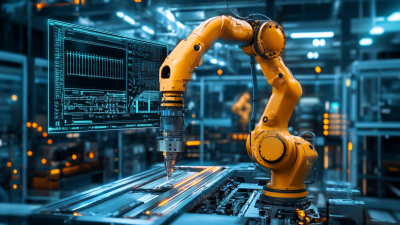

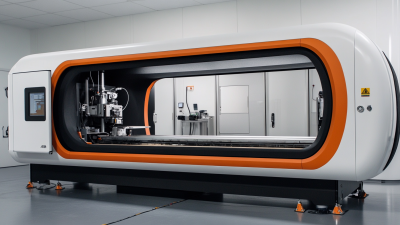

Axis CNC is at the forefront of revolutionizing the manufacturing industry by leveraging innovative technologies that redefine machining capabilities. One of the standout advancements is the integration of 5-axis machining, which offers unparalleled precision and flexibility in manufacturing complex geometries. As production demands evolve, the ability to achieve multi-axis milling significantly enhances the efficiency and accuracy of machined parts, which is crucial in industries where precision is non-negotiable.

Axis CNC is at the forefront of revolutionizing the manufacturing industry by leveraging innovative technologies that redefine machining capabilities. One of the standout advancements is the integration of 5-axis machining, which offers unparalleled precision and flexibility in manufacturing complex geometries. As production demands evolve, the ability to achieve multi-axis milling significantly enhances the efficiency and accuracy of machined parts, which is crucial in industries where precision is non-negotiable.

Moreover, the embrace of advanced software solutions, such as upgraded CAD/CAM systems, plays a pivotal role in Axis CNC's advancements. These technologies not only streamline machining processes but also facilitate better design iterations and optimization. As seen in trends leading into 2025, the adoption of IoT-enabled equipment and AI-driven insights is set to transform traditional manufacturing into a highly connected and intelligent ecosystem. By adopting these innovative tools, Axis CNC is not only enhancing its operational capabilities but also positioning itself as a leader in the rapidly evolving landscape of manufacturing, where adaptability and innovation are key to success.

Enhancing Efficiency: How Axis CNC Reduces Waste and Downtime

In the rapidly evolving manufacturing landscape, Axis CNC is at the forefront of enhancing efficiency through innovative solutions that significantly reduce waste and downtime. With the global CNC controller market projected to reach USD 4.08 billion by 2030, growing at a CAGR of 4.8%, companies are increasingly recognizing the importance of high-performance CNC systems. Axis CNC's advanced technology directly contributes to this trend by streamlining operations and minimizing material wastage, which is crucial in today's cost-sensitive manufacturing environment.

Moreover, the global CNC metal cutting machine tools market is anticipated to be valued at USD 252.67 billion by 2034, demonstrating a robust CAGR of 10.2%. This surge is driven by the rising demand for automation and precision in manufacturing processes. Axis CNC leverages these market dynamics by implementing cutting-edge systems and tools that not only improve throughput but also ensure high product quality while reducing operational downtimes. As manufacturers seek to adapt to changing market demands, Axis CNC stands out as a leader in the shift towards more efficient production workflows, aligning with the broader trends toward smart manufacturing and automation technologies.

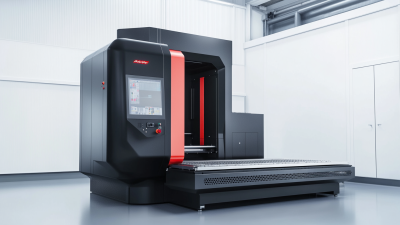

Customizability and Flexibility: A Game Changer for Manufacturers

The manufacturing landscape is undergoing a transformative shift, with Axis CNC leading the charge through unparalleled customizability and flexibility. According to a report from MarketsandMarkets, the global CNC market is projected to reach $117 billion by 2025, underscoring the industry's growing demand for adaptable solutions. Axis CNC's approach enables manufacturers to tailor their machinery to specific project requirements efficiently, setting a new standard for production capabilities. This level of customization not only enhances the precision of manufactured goods but also directly impacts lead times and cost efficiency, crucial factors in today’s competitive market.

Moreover, the flexibility offered by Axis CNC systems allows for rapid reconfiguration, appealing to the emerging trend of small-batch production. A study from Deloitte indicates that 88% of manufacturers are increasingly focusing on agility to meet the diverse needs of their customers. Axis CNC empowers manufacturers to switch between different projects seamlessly, minimizing downtime and maximizing productivity. This capability to pivot quickly in response to market demands places Axis CNC at the forefront of innovation, fostering a manufacturing environment that is responsive and resilient in an ever-evolving landscape.

The Environmental Impact: How Axis CNC Promotes Sustainable Practices

The manufacturing industry is undergoing a significant transformation, with Axis CNC at the forefront of promoting sustainable practices. As global awareness of environmental challenges grows, Axis CNC's commitment to reducing waste and energy consumption stands out. According to a report by McKinsey & Company, sustainable manufacturing can lead to a 30% reduction in CO2 emissions, a statistic that reflects the potential impacts of adopting advanced CNC technologies in production processes. By integrating precision machining and optimized production methods, Axis CNC not only minimizes raw material waste but also enhances overall efficiency, allowing manufacturers to meet increasing demand without compromising environmental integrity.

Moreover, Axis CNC is actively incorporating renewable energy solutions within its operations. The industry's shift toward renewable sources could reduce greenhouse gas emissions by over 70% by 2030, as outlined in a study conducted by the International Renewable Energy Agency (IRENA). By harnessing solar and wind energy for powering CNC machines, Axis CNC is setting a benchmark for sustainable practices that other manufacturers can follow. This move not only demonstrates corporate responsibility but also aligns with the increasing consumer preference for environmentally friendly products, positioning Axis CNC as a leader in both innovation and sustainability within the manufacturing landscape.

Environmental Impact of CNC Manufacturing Practices

This chart illustrates the environmental impact of CNC manufacturing practices. It highlights how these practices contribute to waste reduction, energy efficiency, material recycling, carbon footprint reduction, and water conservation on a scale from 1 to 10.

Related Posts

-

Transforming Manufacturing: 2025 Innovations in CNC Turning Machines & Buyer’s Guide

-

Optimizing Maintenance Costs and Enhancing After Sales Support for Cnc Precision Parts

-

Exploring Cnc Machine Technologies Shaping the Future of Global Manufacturing by 2025

-

Evaluating CNC Parts: Key Factors That Distinguish Quality Suppliers

-

Finding Reliable Suppliers for Your Cnc Machine Tools Needs

-

Discover the Competitive Edge of Axis Cnc for Your Global Manufacturing Needs