Discover the Competitive Edge of Axis Cnc for Your Global Manufacturing Needs

In today’s fast-paced manufacturing landscape, businesses must leverage advanced technology to stay competitive on a global scale. **Axis Cnc** is at the forefront of this transformation, offering innovative solutions that streamline production processes and enhance product quality. As manufacturers seek ways to optimize their operations, understanding the advantages that **Axis Cnc** can provide becomes essential for staying ahead of the curve.

From precision machining to automated processes, **Axis Cnc** equips manufacturers with the tools needed to meet diverse market demands efficiently. This blog will explore how adopting **Axis Cnc** technology can give your business a significant competitive edge, driving productivity and fostering innovation. Join us as we delve into the various features and benefits of **Axis Cnc** that can propel your manufacturing capabilities to new heights in an ever-evolving global marketplace.

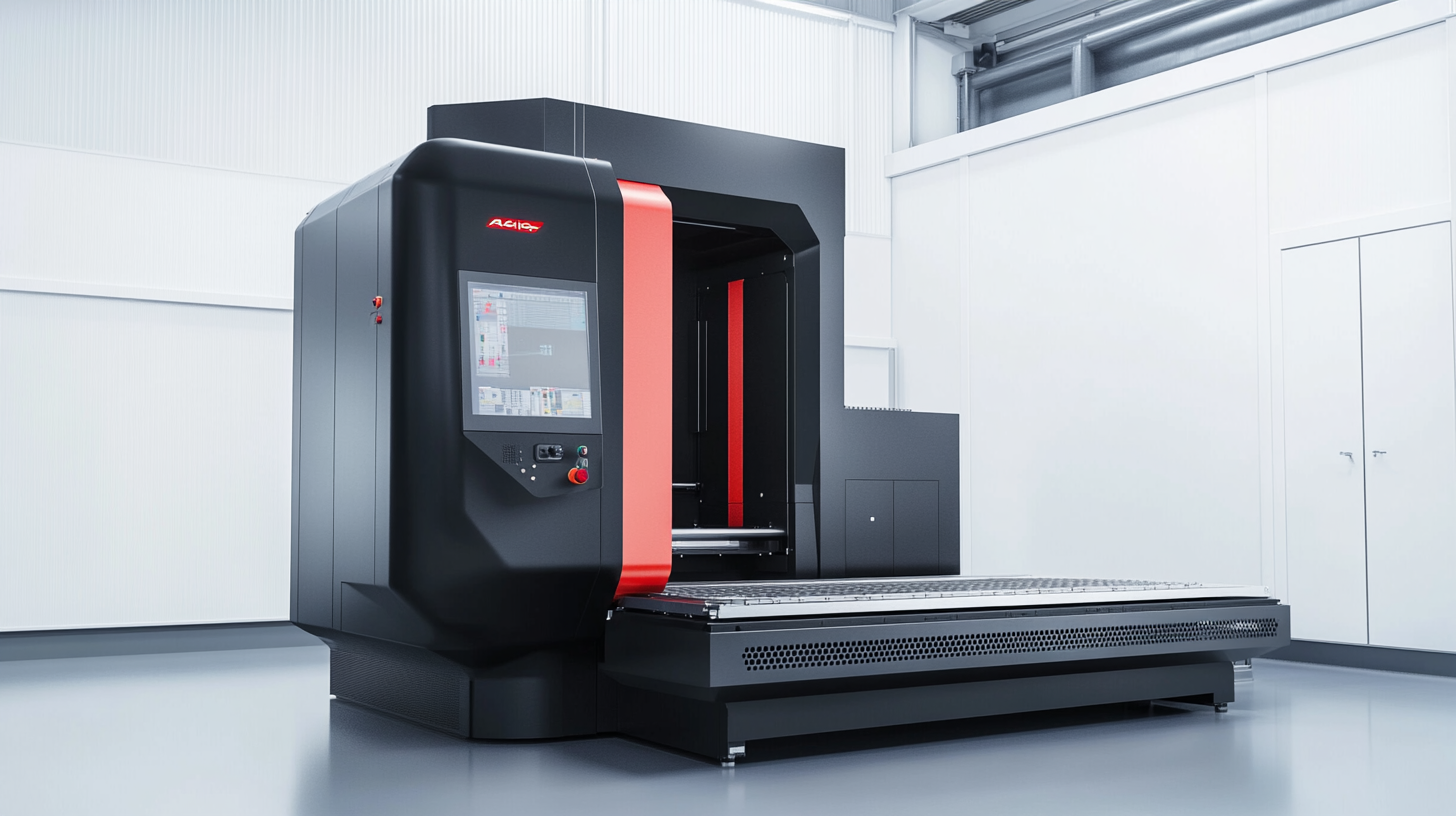

Unleashing Precision: The Advantages of Axis CNC Technology

In today’s rapidly evolving manufacturing landscape, precision and efficiency are paramount. Axis CNC technology has emerged as a key player, enabling businesses to elevate their production capabilities significantly. By utilizing advanced computer numerical control systems, manufacturers can achieve an unparalleled level of accuracy that traditional machining methods simply cannot match. This precision translates into fewer errors, reduced material waste, and ultimately, lower production costs, making Axis CNC a vital asset for companies aiming for excellence. One of the standout advantages of Axis CNC technology is its ability to handle complex geometries with ease. This level of versatility allows manufacturers to produce intricate designs and components that meet the exact specifications of their clients. Furthermore, the consistency offered by CNC machines ensures that each piece produced is identical, promoting uniformity in quality across large production runs. As a result, businesses can confidently scale their operations, knowing that they can consistently deliver high-quality products to a global market. Moreover, the automation capabilities of Axis CNC systems lead to improved workflow efficiency. With reduced manual intervention, production times are accelerated, and the risk of human error is minimized. This allows skilled workers to focus on higher-level tasks, increasing overall productivity. In a competitive global environment, leveraging Axis CNC technology not only enhances operational efficiency but also provides a compelling advantage in meeting customer demands swiftly and effectively.

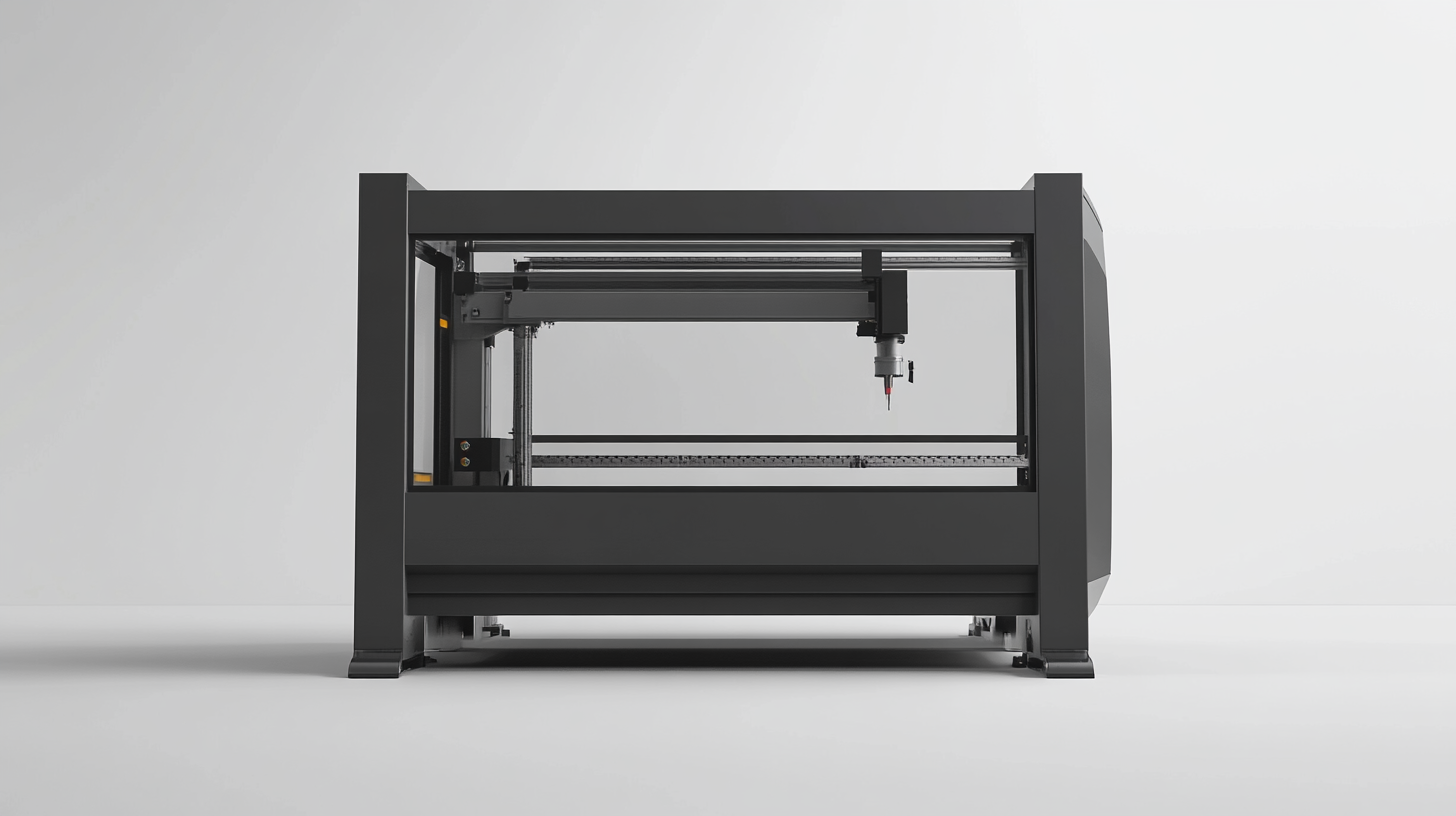

Streamlining Production: How Axis CNC Enhances Efficiency

In the fast-paced world of global manufacturing, efficiency is more than just a goal; it's a necessity. Axis CNC stands out as a cutting-edge solution designed to streamline production processes across diverse industries. By integrating advanced technology and innovative design, Axis CNC machines significantly reduce production times while maintaining precision and quality. This competitive edge allows manufacturers to meet tighter deadlines and respond rapidly to changing market demands.

One of the key features of Axis CNC is its ability to automate various stages of the manufacturing process. Automation minimizes human error and optimizes the workflow, ensuring a smoother transition from one stage of production to the next. Moreover, with sophisticated software capabilities, operators can easily program intricate designs, which leads to faster prototyping and more versatile manufacturing options. The result is a system that not only saves time but also enhances product consistency.

Additionally, Axis CNC machines are built with energy efficiency in mind. By decreasing power consumption without compromising performance, manufacturers can also benefit from lower operational costs. This focus on sustainable production practices not only propels businesses forward but also contributes to environmental conservation. In an era where corporate responsibility is key, Axis CNC helps companies maintain a balance between profitability and sustainability.

Global Reach: Axis CNC's Role in International Manufacturing

In today's interconnected world, the demand for precision manufacturing knows no borders. Axis CNC stands at the forefront of this global manufacturing landscape, providing customers with advanced machining solutions that meet international standards. With their cutting-edge technology and expertise, Axis CNC not only facilitates seamless production but also enhances the efficiency and quality of components used worldwide.

Axis CNC's commitment to global reach ensures that clients from various industries can depend on their services, regardless of where they operate. By leveraging a sophisticated supply chain and advanced logistics, Axis CNC can deliver timely and cost-effective solutions, making it a pivotal player in international manufacturing. Companies looking for reliable partners in their production processes find Axis CNC's infrastructure an invaluable asset, as it supports scalability and adaptability in an ever-evolving market.

Moreover, Axis CNC's proactive approach to international collaboration has fostered partnerships with manufacturers around the globe. This network allows for the exchange of knowledge, technologies, and best practices, further enriching the capabilities of Axis CNC. As businesses strive to meet the challenges of a competitive marketplace, aligning with such an adaptable and globally-minded CNC provider can significantly enhance their manufacturing operations, driving innovation and growth in an increasingly complex environment.

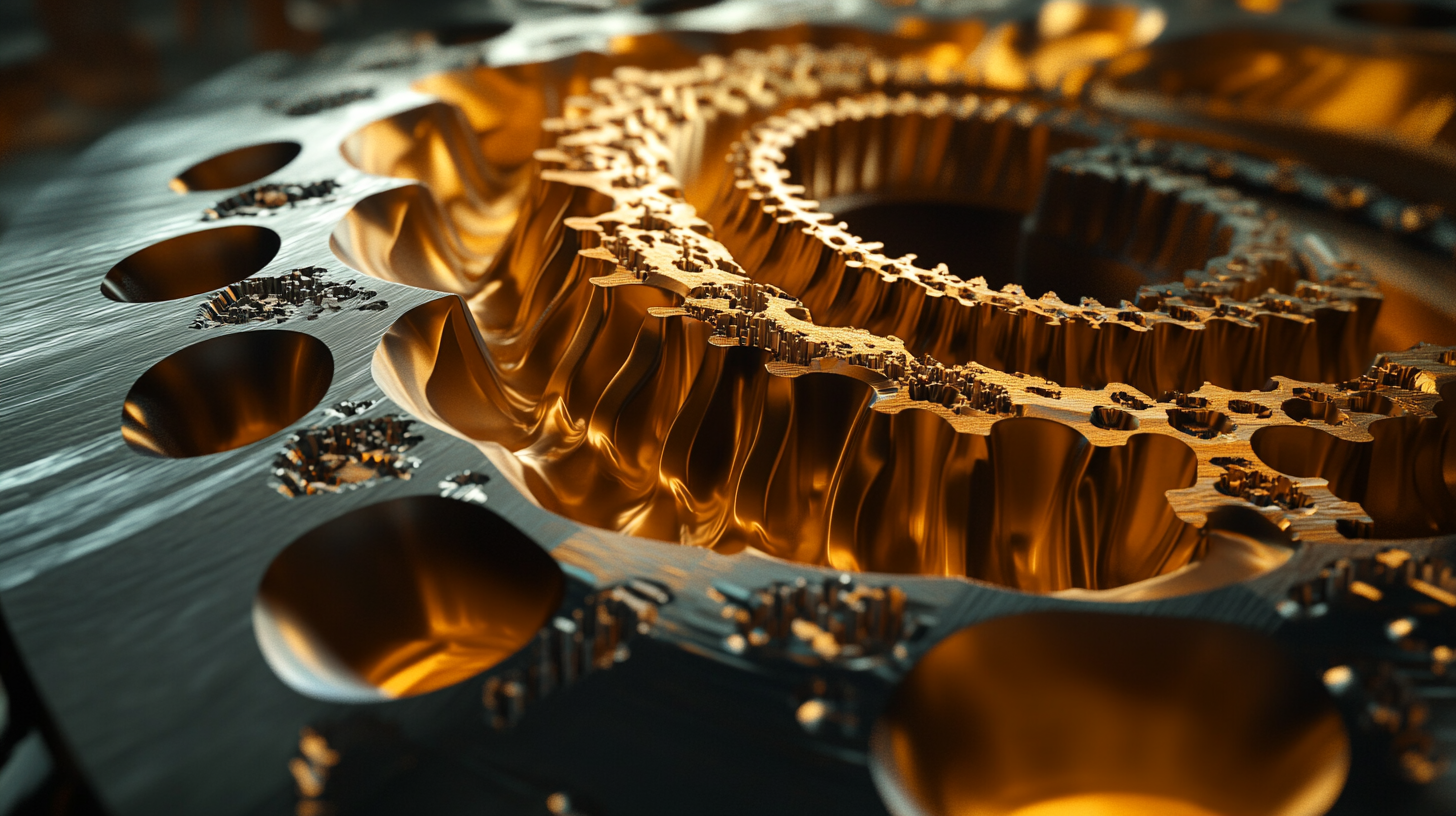

Customization at Scale: Tailored Solutions for Diverse Industries

In today's fast-paced manufacturing landscape, customization at scale has emerged as a vital component for businesses looking to maintain a competitive edge. According to a report by Deloitte, approximately 1 in 3 manufacturers consider customization to be a key differentiator in their market strategy. Axis CNC stands at the forefront of this movement, leveraging advanced technology to provide tailored solutions that meet the diverse needs of various industries.

Axis CNC's commitment to customization enables clients to optimize their production processes, translating to significant cost savings and increased efficiency. For instance, the ability to produce small batch sizes without sacrificing quality equates to a 20-30% reduction in lifecycle costs, as highlighted by a study from McKinsey & Company. This flexibility not only allows manufacturers to meet specific client demands but also fosters innovation, encouraging the development of unique products that stand out in an increasingly crowded marketplace.

Moreover, the integration of Industry 4.0 technologies into Axis CNC's operations enhances the customization potential even further. With the utilization of IoT and AI-driven analytics, manufacturers can gain real-time insights into their production processes, allowing for rapid adjustments and personalized production runs. This kind of responsiveness is invaluable, especially in sectors like aerospace and medical devices, where precision and compliance with stringent regulations are paramount. As global manufacturing continues to evolve, Axis CNC's customized solutions will play a crucial role in helping businesses thrive within their respective markets.

Future-Proofing Your Operations: Axis CNC Innovations and Trends

In the ever-evolving landscape of global manufacturing, staying ahead of the competition requires embracing innovative technologies. Axis CNC is at the forefront of this transformation, offering solutions that not only enhance operational efficiency but also future-proof your manufacturing processes. By integrating advanced CNC machining techniques and software, Axis CNC empowers manufacturers to adapt to changing market demands while maintaining high precision and quality.

One of the key trends driving Axis CNC's innovations is automation. With the rise of Industry 4.0, integrating sophisticated automation systems into machining processes allows manufacturers to increase productivity and reduce human error. These technologies, combined with smart data analytics, enable real-time monitoring and adjustments, ensuring optimal performance and resource utilization. Manufacturers utilizing Axis CNC systems can expect not only shorter lead times but also a significant reduction in operational costs.

Another critical aspect of future-proofing operations is the scalability offered by Axis CNC solutions. As businesses grow or pivot to meet new challenges, Axis CNC provides flexible options that can be easily adapted or expanded. This agility is crucial in today’s global market, where customization and rapid response to customer needs can make all the difference. By choosing Axis CNC, manufacturers can invest in a system that evolves with them, ensuring sustained competitiveness now and into the future.