What Are the Benefits of Using Injection Molding Machines With Robots?

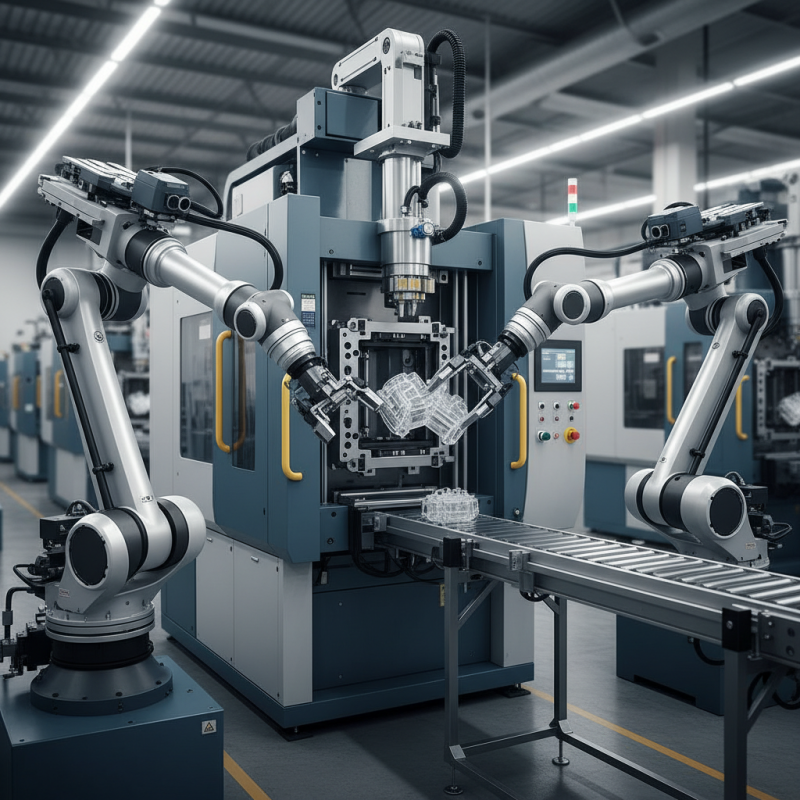

The manufacturing industry is rapidly evolving. One significant advancement is the integration of an Injection Molding Machine With Robot technology. This combination enhances efficiency and precision in production processes. Notably, robots can handle tasks that require speed and accuracy, which humans might find challenging.

Using an Injection Molding Machine with a Robot enables manufacturers to streamline their operations. Automation reduces labor costs and minimizes human error. This results in improved product quality. However, some companies remain hesitant to adopt this technology. They fear the initial investment may not be worth the long-term benefits.

In reality, the potential for increased output and reduced cycle times is substantial. Nevertheless, not all businesses fully understand these benefits. Continuous education and training are crucial for understanding how to implement this technology effectively. The transition might be imperfect, but the advantages are clear.

Benefits of Automation in Injection Molding Processes

Automation in injection molding processes offers significant advantages that enhance production efficiency. The integration of robots in these operations can improve cycle times by up to 30%, according to a report by the International Society of Automation. This increase in speed leads to higher output rates. Rapid production allows manufacturers to meet market demands promptly.

Robotic systems also reduce labor costs. A study published by the Association for Manufacturing Technology indicates that companies can save up to 25% on labor expenses by automating repetitive tasks. As robots handle material loading and part extraction, human workers can focus on quality control and complex assembly. However, there’s a potential downside. Companies must invest significantly in these technologies, which can be a barrier for smaller businesses.

Moreover, the reliability of robots in consistent performance can vary. While they can reduce errors, programming issues can lead to production delays. Industry analysts suggest that training staff to handle these automated systems is crucial. It ensures smooth transitions and avoids costly downtime. The potential for reduced waste and improved quality is enticing, yet the initial hurdles must be navigated carefully.

Enhanced Precision and Consistency in Production

Using injection molding machines with robots brings enhanced precision and consistency to production. This integration results in more accurate parts. The robots take over tasks that require high precision. They reduce human error, which can affect quality. Automation streamlines the manufacturing process. Every cycle is consistent, ensuring that parts meet exact specifications.

One tip for optimizing this system is to regularly calibrate both the injection molding machine and the robots. Calibration ensures tight tolerances are maintained. Additionally, training staff on robotic functions can reduce operation errors. Proper training will empower workers to troubleshoot minor issues efficiently.

While robotic integration enhances efficiency, challenges exist. For instance, the initial setup can be time-consuming. It may require adjustments to existing processes. Frequent maintenance is necessary to keep robots at their best performance. Reflecting on these challenges is important for long-term success in automated molding. Balancing precision with flexibility can maximize production advantages.

What Are the Benefits of Using Injection Molding Machines With Robots? - Enhanced Precision and Consistency in Production

| Benefit | Description | Impact on Production |

|---|---|---|

| Enhanced Precision | Robots ensure accurate placement of materials and parts, reducing errors. | Leads to higher quality products and reduced scrap rates. |

| Increased Consistency | Automation provides uniformity in production output. | Minimizes variations in product quality. |

| Higher Efficiency | Robots perform tasks faster than human labor with continuous operation. | Increases overall production speed and volume. |

| Labor Cost Savings | Reduced reliance on manual labor reduces labor costs. | Improves profitability and allows for reinvestment in technology. |

| Flexibility in Production | Robotic systems can be reprogrammed for different tasks. | Allows for quick adaptation to changing production needs. |

Reduced Labor Costs and Increased Efficiency

Injection molding machines integrated with robots are transforming the manufacturing sector. One significant advantage is reduced labor costs. Automation can cut labor expenses by over 25%. This reduction comes from fewer workers needed on the factory floor. Robots can handle repetitive tasks efficiently, minimizing the risk of human error.

Increased efficiency is another key benefit. Studies show that automating injection molding can improve cycle times by 30%. Robots can work continuously without breaks. They can also perform tasks at high speeds, allowing manufacturers to increase their production rates. In terms of energy management, automated systems often consume less power over time.

Despite these benefits, challenges exist. Transitioning to a robotic system involves initial investments and training. Workers may feel apprehensive about job security. Additionally, while robots excel in efficiency, complex problem-solving still requires human oversight. Addressing these issues is crucial for successful implementation. Balancing automation with human skill will enhance productivity without compromising employment stability.

Benefits of Using Injection Molding Machines With Robots

Improved Safety and Risk Management in Manufacturing

The integration of injection molding machines with robots significantly enhances safety and risk management in manufacturing. According to industry reports, around 90% of workplace injuries occur due to human error. By automating processes, robots can take over hazardous tasks. This reduces the reliance on human labor in dangerous environments. For example, loading and unloading heavy materials can lead to injuries, but robots perform these tasks efficiently and safely.

Additionally, the use of robots minimizes the risks associated with repetitive strain injuries. Human workers often face long hours of monotonous tasks. A study indicates that job rotation and breaks can reduce strain, yet robots do not require such adjustments. They operate continuously without the health risks associated with long-term repetitive work. This allows human operators to focus on supervision and quality control.

Implementing robotic systems does come with challenges. Initial costs can be high, and staff must be trained. The integration process can also disrupt existing workflows. However, the long-term benefits of improved safety are hard to ignore. As manufacturing evolves, companies must weigh these factors carefully. Balancing productivity with worker safety is critical for sustainable growth in the industry.

Flexibility and Scalability of Production Systems

Injection molding machines paired with robots offer significant flexibility and scalability. This combination allows for quick adjustments to production lines. Manufacturers can respond swiftly to changing demands. For instance, if a new product needs to be launched, robotic systems can reprogram easily.

Robots streamline the injection molding process. They handle tasks like loading materials and removing finished products. This reduces human labor and enhances precision. However, integration can be tricky. Not all processes may align perfectly. Testing and modifications may be necessary.

Production scalability improves significantly with this setup. Businesses can start small and expand as needed. Incremental changes can lead to larger outputs. But, one must consider energy costs and maintenance. Balancing productivity with expenses requires careful thought. Robots bring efficiency, yet they also need regular checks and updates.