Ultimate Checklist for Choosing the Right Industrial CNC Machine for Your Business

When it comes to optimizing manufacturing processes, selecting the right Industrial CNC Machine plays a pivotal role in enhancing productivity and ensuring precision. According to a recent report by MarketsandMarkets, the global CNC machine market is projected to reach $100 billion by 2025, driven by the increasing demand for automation in various industries. As businesses strive to improve efficiency and reduce operational costs, having an appropriate CNC machine that fits their specific needs is more critical than ever. A well-chosen Industrial CNC Machine not only boosts output but also significantly lowers waste, aligning with sustainability goals that are becoming increasingly important in today’s manufacturing landscape. In this blog, we will provide you with an ultimate checklist and top strategies to help you make an informed decision when investing in an Industrial CNC Machine for your business.

Factors to Consider When Exploring CNC Machine Alternatives

When exploring CNC machine alternatives, it’s essential to consider several key factors that align with your business's goals. The evolution of technologies, particularly artificial intelligence and machine learning, has drastically changed the landscape of CNC machinery. These advancements allow for enhanced precision, efficiency, and the ability to integrate into a circular economy, minimizing waste and maximizing value from resources.

Tip 1: Evaluate the machine's adaptability to new technologies. A CNC machine that can integrate seamlessly with AI-driven software will optimize your production processes and help reduce operational costs.

Tip 1: Evaluate the machine's adaptability to new technologies. A CNC machine that can integrate seamlessly with AI-driven software will optimize your production processes and help reduce operational costs.

In addition to technological compatibility, consider the long-term sustainability of the machinery you choose. As industries move towards greener practices, select machines that are energy-efficient and capable of utilizing renewable resources. This not only aligns your business with sustainable progress but can also attract environmentally conscious customers.

Tip 2: Research manufacturers that offer machines designed for energy efficiency and sustainable materials. This foresight can lead to significant savings and a positive impact on your brand image in the marketplace.

Comparing Different CNC Machine Technologies for Industrial Needs

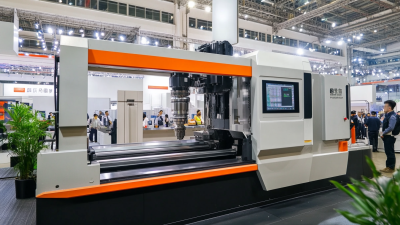

When selecting the right industrial CNC machine, understanding the different technologies available is crucial.

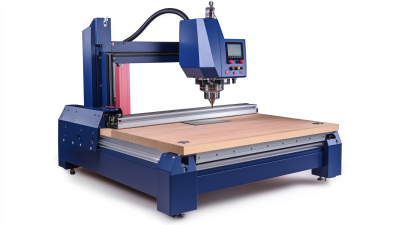

CNC milling machines are incredibly versatile, capable of handling a wide variety of materials, including metals and plastics.

They excel in producing complex parts and offer a high level of precision. For businesses focusing on accuracy and fine details, investing in a high-quality CNC mill can significantly enhance quality and efficiency.

Tip: Always consider the machine's compatibility with your existing tools and software. Integration can save time and reduce the learning curve for your staff.

Furthermore, explore emerging technologies like CNC plasma cutters, which are excellent for cutting metal sheets with speed and efficiency. They offer a cost-effective solution for businesses looking to streamline operations without sacrificing quality.

Tip: Analyze the support and maintenance options offered by manufacturers, as reliable customer service can make a significant difference in minimizing downtime.

Evaluating Cost-Effectiveness of CNC Machine Options

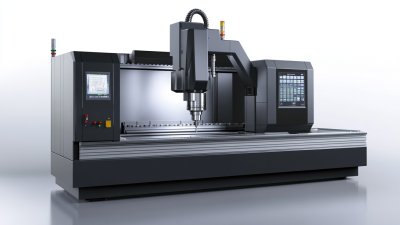

When selecting the right industrial CNC machine for your business, evaluating cost-effectiveness is crucial. According to recent industry analyses, making decisions solely based on cost can lead to suboptimal machine selections. A multi-criteria decision-making approach aligns with the needs of both manufacturing and construction firms aiming for profitability. By considering additional factors such as energy consumption and productivity enhancements, companies can make more informed choices that yield better long-term returns.

The integration of advanced features in vertical machining centers significantly increases productivity, allowing businesses to optimize their manufacturing processes. A systematic literature review highlights that between 15% to 30% improvement in energy efficiency can be achieved with the right CNC machines by focusing on sustainable practices. Furthermore, adopting CAD/CAM systems can streamline workflows and enhance overall shop productivity, enabling smaller manufacturers to harness the advantages of additive manufacturing technologies.

Cost-effectiveness also involves evaluating the total cost of ownership rather than just the initial investment. The recent launch of cost-effective coordinate measuring machines (CMM) provides manufacturers with alternative solutions for transitioning from manual to automated measurements without breaking the bank. As industries continue to evolve, embracing innovative machinery options becomes essential for maintaining competitiveness and driving sustained growth.

Ultimate Checklist for Choosing the Right Industrial CNC Machine for Your Business - Evaluating Cost-Effectiveness of CNC Machine Options

| Machine Type | Initial Cost ($) | Maintenance Cost (Annual) ($) | Production Rate (Units/Hour) | Energy Consumption (kWh/Hour) | Return on Investment (ROI) |

|---|---|---|---|---|---|

| CNC Router | 15,000 | 1,500 | 30 | 5 | 20% |

| CNC Mill | 25,000 | 2,000 | 20 | 7 | 15% |

| CNC Plasma Cutter | 10,000 | 800 | 50 | 3 | 25% |

| Laser Cutter | 35,000 | 2,500 | 15 | 10 | 10% |

Assessing Compatibility of Alternatives with Existing Systems

When selecting an industrial CNC machine, one of the most crucial aspects to consider is its compatibility with your existing systems. A report by the International Society of Automation (ISA) indicates that nearly 70% of manufacturers experience downtime during machine integration due to incompatibility issues. Thus, assessing whether a CNC machine can seamlessly integrate into your current operations is essential for optimizing productivity and minimizing disruptions.

Additionally, understanding the specific requirements of your existing systems, such as software compatibility and communication protocols, can save both time and cost. According to a study by the Association for Manufacturing Technology (AMT), companies that conducted thorough compatibility assessments before purchasing new machinery reported a 45% reduction in integration time. This highlights the importance of aligning new CNC machines with the existing technology infrastructure to ensure smooth operations and a swift return on investment. By focusing on compatibility, businesses can enhance their operational efficiency and stay competitive in a rapidly evolving market.

Understanding the Benefits of Choosing Non-Traditional CNC Machines

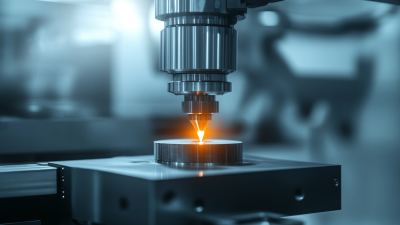

When it comes to selecting the perfect CNC machine for your business, exploring non-traditional options can lead to remarkable benefits. Non-traditional CNC machines often incorporate innovative technologies like laser cutting, water jet machining, and 3D printing. These alternatives can significantly enhance production capabilities, offering greater versatility for complex projects that standard machines may struggle with. By leveraging these advanced techniques, businesses can produce intricate designs with higher precision and reduced waste, ultimately leading to cost savings and improved efficiency.

Furthermore, non-traditional CNC machines allow for greater adaptability in manufacturing processes. In an ever-evolving market, the ability to quickly adjust to new specifications or materials is vital. For instance, a business can transition from producing metal parts to intricate plastic components without the need for extensive retooling. This flexibility not only fosters creativity in product design but also encourages innovation, making it easier for companies to stay ahead of industry trends and customer demands. Embracing non-traditional CNC machines is not just about keeping up; it's about setting the pace for future advancements in manufacturing.

Comparison of Traditional vs. Non-Traditional CNC Machines

This chart provides a comparison between traditional and non-traditional CNC machines, highlighting their costs and maintenance frequencies. Non-traditional CNC machines generally have a lower initial investment and less frequent maintenance requirements, making them an attractive option for many businesses.

Related Posts

-

Essential Guide: 10 Key Features to Evaluate When Choosing an Industrial CNC Machine

-

Exploring Top Strategies to Source Reliable Home Cnc Machine Suppliers Globally

-

Ultimate Comparison of Best Cnc Machine Tools for Precision Manufacturing in 2023

-

Exploring Opportunities for Multi Axis CNC Machine at the Successful 137th China Import and Export Fair

-

Ultimate Guide to Sourcing the Best CNC Precision Parts: Key Insights and Industry Trends

-

Finding Reliable Suppliers for Your Cnc Machine Tools Needs