Strength from China's Leading Factory Powers Global Trust in Innovative Small Milling Machines

In recent years, the global manufacturing landscape has witnessed a significant transformation, driven by the rising demand for precision engineering and enhanced production efficiency. Among the key players in this shift are China's leading factory sectors, which have emerged as formidable contributors to the advancement of innovative small milling machines. According to a report by Markets and Markets, the small milling machine market is projected to grow at a CAGR of 6.2%, reflecting an increasing reliance on compact machinery to meet diverse manufacturing needs. With China's robust supply chain and commitment to technological innovation, these small milling machines are not only gaining traction domestically but are also establishing trust among international markets. Businesses are increasingly recognizing the value of incorporating these advanced tools into their operations, underscoring the pivotal role that China plays in shaping the future of milling technology worldwide.

The Rise of China's Small Milling Machines in Global Markets

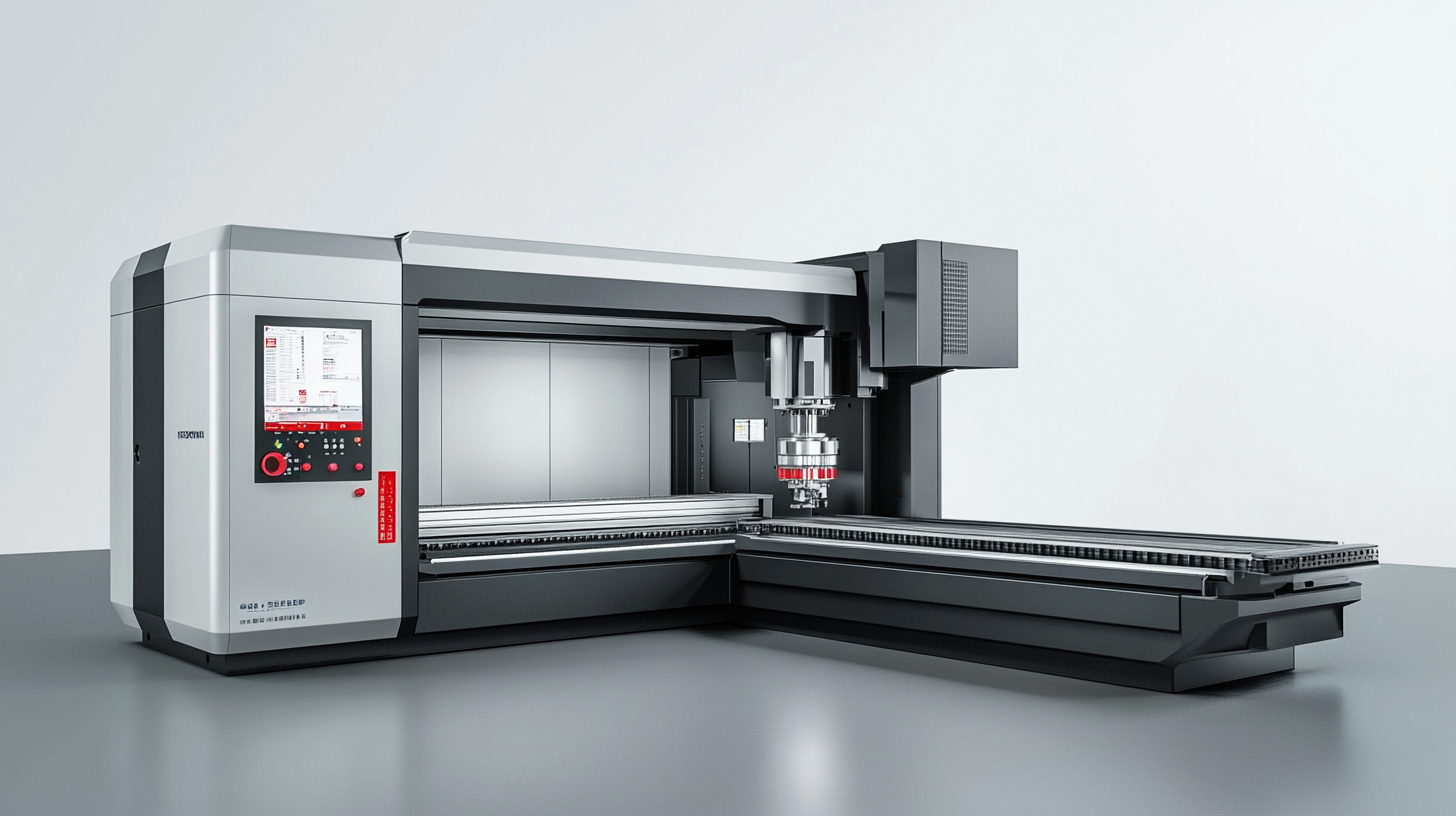

China has witnessed a significant surge in the production and export of small milling machines, positioning itself as a formidable leader in the global market. These innovative machines, known for their compact designs and efficiency, have captured the attention of manufacturers and artisans worldwide. The rise of Chinese small milling machines is attributed to their advanced engineering and cost-effectiveness, providing a competitive edge that appeals to businesses seeking reliable yet affordable milling options.

As industries evolve, the demand for versatile machinery that can adapt to various tasks has increased. China's small milling machines respond to this need by offering a range of functionalities that address different manufacturing challenges. The integration of cutting-edge technology allows these machines to produce intricate designs with precision, making them indispensable in sectors such as woodworking, metalworking, and even prototyping. Consequently, global trust in China's manufacturing capabilities is growing, reinforcing its status as a leader in the milling machine market.

Innovative Features That Set Chinese Milling Machines Apart

China's small milling machines are gaining global recognition due to their innovative features and advanced technology. These machines incorporate precision engineering and superior automation, allowing users to achieve high levels of accuracy and efficiency in their milling processes. With advancements in smart manufacturing, many Chinese manufacturers have integrated IoT (Internet of Things) capabilities into their equipment, enabling real-time monitoring, data collection, and analysis, which significantly enhances production workflows.

Another standout characteristic of Chinese milling machines is their adaptability. Many models can be easily customized to suit various industrial needs, making them versatile tools for different manufacturing sectors. From aerospace to automotive, these machines offer specialized attachments and software that improve functionality and precision. Moreover, the robust build quality and competitive pricing make them an attractive option for businesses looking to upgrade their milling capabilities without compromising on performance. As a result, China's innovative milling machines are not only boosting domestic production but also earning trust and respect in markets worldwide.

Addressing Quality and Reliability in Manufacturing

In recent years, China's manufacturing landscape has significantly evolved, with an emphasis on quality and reliability, particularly in the production of innovative small milling machines. With the government's backing through initiatives like the "Made in China 2025" plan, manufacturers are focusing on enhancing product standards and consistency. This strategic move not only positions Chinese manufacturers favorably on the global stage but also fosters trust among consumers and businesses alike.

Tips for manufacturers looking to enhance quality and reliability include investing in rigorous testing and certification processes. Establishing a robust quality management system can serve as a foundation for ensuring that products meet the required standards both domestically and internationally. Furthermore, continuous employee training in the latest manufacturing technologies and practices can lead to innovation and improved product quality.

Additionally, collaboration with international quality standards organizations can provide valuable insights and benchmarks. By aligning manufacturing processes with global best practices, companies can advance their reputation and expand their market reach. Embracing these strategies will not only lead to improved quality in production but also ensure long-term success in a competitive global market.

The Role of Technology in Enhancing Milling Machine Performance

The performance of milling machines has significantly improved due to advancements in technology, playing a crucial role in their increased efficiency and precision. Innovations in semiconductor manufacturing processes have directly contributed to the development of more sophisticated milling machines. As companies invest in cutting-edge technologies, the incorporation of advanced features enhances the functionality of these machines, making them indispensable in various industries.

Tips for optimizing milling machine performance include focusing on the integration of high-quality sensors and automation technologies. These additions can provide real-time data for better decision-making and maintenance strategies. Additionally, regular software updates and the use of smart algorithms can significantly enhance the productivity and lifespan of milling machines, ensuring they remain competitive in a rapidly evolving market.

Furthermore, it is essential to stay informed about the latest technological developments in the field. Engaging with industry innovations, such as advanced materials and AI-driven processes, allows manufacturers to leverage these technologies, leading to improved production capabilities and overall trust in their milling machines. Embracing these advancements not only boosts operational efficiency but also fosters a culture of continuous improvement within organizations.

Building Trust Through Customer Support and After-Sales Service

In the competitive landscape of manufacturing, exceptional customer support and after-sales service stand out as pivotal elements that foster trust between companies and their clients. Small milling machines from China's leading factories are not just celebrated for their innovative design and efficiency, but also for the robust support systems backing them. These manufacturers prioritize establishing long-term relationships with their customers, ensuring that any issues that arise post-purchase are addressed promptly and effectively. This commitment to service reassures clients that they are investing in a reliable product, thus enhancing customer loyalty and brand reputation.

Moreover, a strong after-sales service network often includes training programs, spare parts availability, and dedicated customer service representatives ready to assist. Such proactive measures not only mitigate potential downtime for clients but also empower them to maximize the capabilities of their milling machines. As customers experience the attentiveness and responsiveness of support teams, their trust in the brand deepens, making them more likely to recommend these innovative solutions within their industries. In this way, China's leading factories are not merely selling products; they are building a trust foundation that influences global acceptance and reliance on their technology.

Customer Trust in Innovative Small Milling Machines

This pie chart illustrates the factors contributing to customer trust in China's innovative small milling machines. The data reflects the importance of customer support, product quality, and after-sales service.