Why Choose a Horizontal Machining Center for Your Shop?

Investing in a Horizontal Machining Center can transform your shop's productivity. This advanced machining tool is designed to maximize efficiency and precision. With its unique design, it enables multiple-axis machining and saves time on setups.

Operators can load and unload parts while the machine works on another. This dual function minimizes downtime and increases output. However, choosing a Horizontal Machining Center must align with your shop’s specific needs. It’s not just about speed; precision matters too.

Consider the skills of your team and the complexity of your projects. Some shops may struggle to adapt to such technology. Factors like training and maintenance become crucial in this decision. Investing in a Horizontal Machining Center can yield significant benefits but requires careful planning. It's a leap that must be taken with clarity and intent.

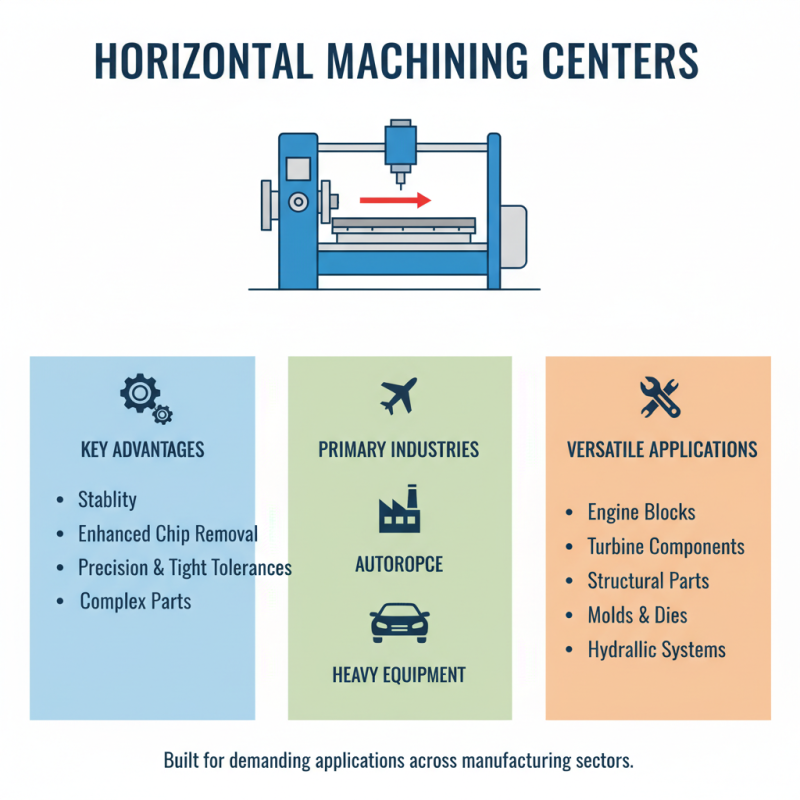

Benefits of Horizontal Machining Centers in Modern Manufacturing

Horizontal machining centers (HMCs) are increasingly preferred in modern manufacturing. They offer distinct advantages. For instance, HMCs often reduce cycle times by 30% compared to vertical machines. This improvement stems from their ability to perform multiple operations simultaneously. As a result, shops can produce more parts in less time.

Another benefit is the enhanced accuracy and quality of machined parts. According to a recent industry report, HMCs achieve tolerances of up to 0.001 inches. This precision helps manufacturers meet stringent quality standards. However, the initial investment can be significant. Some companies might hesitate to make this leap, fearing financial strain.

Additionally, horizontal centers are well-suited for complex components. They can handle larger workpieces more efficiently, thanks to their robust design. Data indicates that about 45% of companies experience increased versatility in their operations after adopting HMCs. Yet, operators need proper training to harness their full potential. The learning curve can be steep, which might discourage some businesses from transitioning.

Key Features of Horizontal Machining Centers to Consider

When considering a horizontal machining center, several key features stand out. One of the most significant aspects is the ability to handle larger workpieces. According to a report from the National Tooling and Machining Association, over 60% of shops find themselves limited by the size of the machines they use. Horizontal centers often accommodate these larger sizes, allowing for more complex operations and increased productivity.

Another essential feature is the improved chip removal systems. These machines often include advanced cooling and chip management systems. A study by the American Society of Mechanical Engineers shows that efficient chip removal can reduce cycle times by up to 30%. However, achieving this efficiency requires a careful setup and may not always be straightforward. Many operators face challenges in optimizing these systems for different materials.

Tool access and setup flexibility also play crucial roles in selecting horizontal machining centers. The design allows for multiple setups without repositioning the workpiece. This can lead to significant time savings. However, it also means operators must be meticulous in their setup processes. Many shops report a steep learning curve when transitioning to these machines. While the investments often pay off, clear understanding and proper training are essential for success.

Comparison of Horizontal and Vertical Machining Centers

When comparing horizontal and vertical machining centers, several factors come into play. Horizontal machining centers are known for their stability and efficiency. They handle larger workpieces more effectively. This design often allows for better chip removal, optimizing the machining process. In contrast, vertical centers are more versatile for smaller tasks. They offer ease of use and setup for a range of projects.

However, horizontal machining centers can be less flexible. Their setup can be more complex, requiring careful planning. On the other hand, vertical centers may struggle with larger, heavier components. They can sometimes lead to increased cycle times for heavier materials. Each machine type has distinct advantages and drawbacks that should be carefully evaluated.

Choosing the right center can impact production significantly. A horizontal machining center excels in high-volume operations with uniform parts. Yet, it may not be suitable for quick, small-scale projects. In contrast, a vertical center can adapt quickly to changing jobs but might lack efficiency in high-demand scenarios. Reflecting on your shop's specific needs is essential for making the right choice.

Why Choose a Horizontal Machining Center for Your Shop?

| Feature | Horizontal Machining Center (HMC) | Vertical Machining Center (VMC) |

|---|---|---|

| Chip Removal | Better due to gravity | Can clog; less efficient |

| Setup Time | Longer for complex parts | Typically shorter |

| Work Envelope | Larger; accommodates larger parts | Generally smaller |

| Precision | Higher stability on large parts | Excellent for smaller parts |

| Tool Access | Easier access for multiple setups | Limited access |

| Production Capability | Excellent for high-volume production | Versatile for low to medium volumes |

Applications and Industries Best Suited for Horizontal Machining

Horizontal machining centers are highly versatile machines. They excel in a range of applications across many industries. These machines are particularly effective in aerospace, automotive, and heavy equipment manufacturing. Complex parts with tight tolerances require precise machining. The horizontal setup provides stability and improved chip removal, making it ideal for these tasks.

In aerospace applications, parts often need intricate details. The ability to achieve high precision is crucial here. Similarly, the automotive industry benefits from horizontal machining. Mass production demands efficiency and quality. Horizontal centers can handle multiple operations in one setup. This reduces time and increases productivity, yet it requires skilled operators to maximize the machine's potential.

Further, industries like oil and gas utilize horizontal machining for larger components. This encourages innovation but can pose challenges. Operators must adapt to the unique properties of each material. Mistakes in machining can lead to significant costs. Therefore, understanding the application is key. Ensuring that the machining center is used correctly can help reduce errors and improve overall productivity.

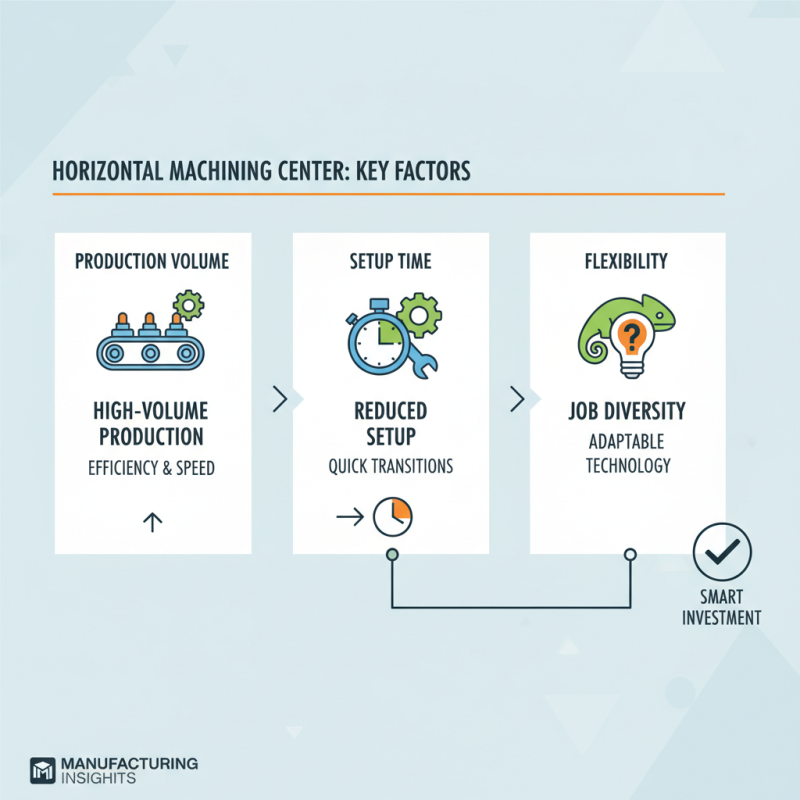

Factors Influencing the Decision to Invest in Horizontal Machining Centers

When considering a horizontal machining center, several key factors can guide your decision. First, the production volume matters. These machines excel in high-volume production, offering efficiency and speed. The setup time is reduced, allowing quick transitions from one job to another. If your shop demands such flexibility, investing in this technology may be wise.

Cost is another critical aspect. Horizontal machining centers can be pricey. However, their capabilities often justify the investment. You should analyze your budget carefully. Will the potential increase in productivity outweigh the initial costs? Additionally, consider workforce training. Operators may need time to adapt.

Maintenance requirements also play a role. These machines may need regular upkeep to operate effectively. Ensure your team is prepared for this responsibility. Balancing these factors can lead to a fruitful investment. However, each shop's unique needs will influence the final decision. Reflect on your current challenges and future goals before proceeding.

Related Posts

-

Precision CNC Machining vs Traditional Manufacturing A Comprehensive Analysis of Efficiency and Cost Effectiveness

-

Exploring Top Strategies to Source Reliable Home Cnc Machine Suppliers Globally

-

The Ultimate Guide to Choosing the Best CNC Parts for Your Project

-

What is Cnc Machining Parts and How They Transform Modern Manufacturing

-

Ultimate Checklist for Choosing the Right Industrial CNC Machine for Your Business

-

5 Reasons Why Axis CNC Machines Boost Manufacturing Efficiency by 40 Percent