How to Choose the Best Metal Milling Machine for Your Needs?

Choosing the best Metal Milling Machine can be challenging. The right machine impacts efficiency and product quality. Recent industry reports indicate that the demand for precision machining is growing rapidly. By 2026, the metal machining market is projected to reach $95 billion.

Selecting the appropriate Metal Milling Machine involves understanding specific needs. For instance, different materials require varied cutting tools. Metal types like aluminum and steel behave differently when milled. Many users overlook the machine's compatibility with their material. Additionally, considering the machine's horsepower and speed is crucial. These factors can significantly influence production rates.

Many potential buyers may underestimate the importance of machine stability. A less stable machine can lead to inaccuracies. Tolerance levels are vital for high-quality machining. Understanding your production requirements can help avoid costly mistakes. Investing time in research ultimately pays off. The right Metal Milling Machine is not just a tool; it shapes your manufacturing future.

Understanding the Basics of Metal Milling Machines

Metal milling machines are vital in manufacturing. They shape and cut metal into desired forms. Understanding the basics can significantly impact your choice. These machines operate using rotary cutters, removing material from solid workpieces. According to a report by Grand View Research, the global CNC milling machine market was valued at approximately $8.5 billion in 2020. This growth underscores their importance in metalworking.

There are different types of milling machines. Some are small and portable, while others are large and fixed. The right choice depends on your specific needs. For instance, if you require intricate designs, a CNC machine might be beneficial. However, it can be complex to operate. A manual mill is simpler but may not provide the precision required for detailed work.

The choice of materials also matters. Steel and aluminum are common, but they behave differently. Steel requires more power and may lead to faster wear and tear on tools. In contrast, aluminum is easier to machine, but can be prone to chatter. These factors need careful consideration. Your experience level affects your choice as well. Beginners may find certain machines more challenging than others.

Key Features to Consider When Selecting a Milling Machine

When selecting a metal milling machine, consider key features that align with your specific needs. One important aspect is the machine's size. A compact machine may fit in a small workshop. However, larger machines typically offer more stability and power. Assess your workspace carefully before making a decision.

Cutting speed is another critical feature. It determines how efficiently the machine operates. Higher speeds can enhance productivity but may require more robust tooling. Pay close attention to the materials you plan to mill. Different materials necessitate varied milling speeds. Consider how often you will change tasks and adjust accordingly.

The control system is equally essential. Digital controls offer precision and ease of use. However, some users prefer manual controls for a hands-on approach. Find a balance that suits your workflow. Remember, no machine fits all needs perfectly. Evaluating these factors can help in making an informed choice.

Key Features Comparison of Metal Milling Machines

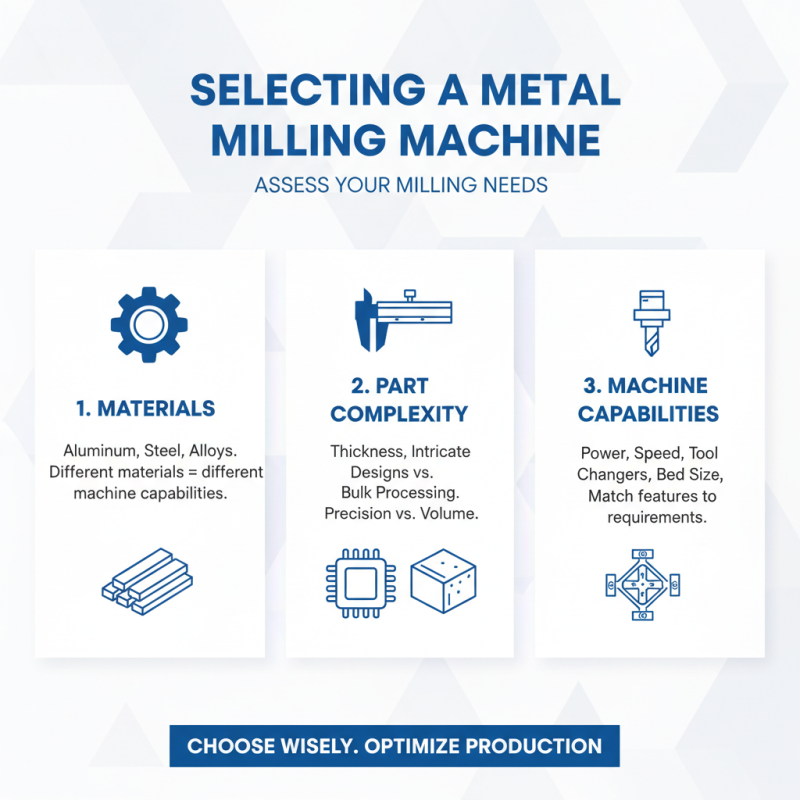

Assessing Your Specific Milling Needs and Applications

Assessing your specific milling needs is crucial when selecting a metal milling machine. Start by identifying the materials you will work with. This could include aluminum, steel, or other alloys. Each type of material may require different milling capabilities. Consider the thickness and complexity of the parts you plan to create. Some machines excel with intricate designs, while others focus on bulk processing.

Think about the scale of your projects. Will you be milling small, detailed components or larger pieces? The size of your work area is also a factor. You need a machine that fits your workspace. Be mindful of the machine's weight and power requirements, too. If you're a hobbyist, a smaller machine may suffice. However, a industrial setup could demand something more robust.

Evaluate your skill level. A beginner might struggle with complicated features. Yet, advanced users may find restrictions frustrating. It’s worth considering future projects as well, not just current ones. This means reflecting on your growth as a machinist. Balancing your immediate needs with potential future use is essential. Don’t overlook the importance of maintenance needs. Some machines require extensive upkeep, which could be daunting for some users.

Comparing Different Types of Metal Milling Machines

When considering different types of metal milling machines, it's crucial to understand their unique features. Vertical milling machines are popular for their versatility. They allow for various cutting operations. This makes them suitable for both small and large projects. However, they may lack the capacity for heavy-duty work.

Horizontal milling machines excel in production. Their robust design enhances stability during operation. This is ideal for larger workpieces. But, they can be more challenging to set up and operate. Users might find the initial learning curve steep. Not everyone is comfortable with the layout and mechanics.

CNC milling machines represent advanced technology. They offer high precision and automation. This can reduce human error significantly. However, they typically come at a higher cost. Beginners might feel overwhelmed by programming requirements. Thus, choosing the right type hinges on your specific tasks. Assess your comfort level and project needs before deciding.

Budgeting and Cost Considerations for Your Milling Machine Purchase

When budgeting for a metal milling machine, several factors come into play. The average cost varies widely, ranging from $2,000 to over $50,000. A detailed industry report indicates that approximately 65% of small businesses allocate around $10,000 for their first milling machine. This budget typically supports entry-level models that can meet basic machining needs.

Consider your production volume. If you are a small shop with occasional milling tasks, a lower budget machine may suffice. However, if you anticipate higher demand, investing more upfront can save costs in the long run. According to a 2022 industry survey, companies that spent 20% more on advanced features reported a 30% increase in productivity.

Think about additional costs too. Maintenance, tooling, and software may elevate your total expenditure. On average, these costs can add another 15-20% to your initial budget. Buyers often overlook these factors, leading to financial strain later. Reflecting on actual expenses is crucial. Balancing upfront cost with long-term efficiency will guide you towards a well-informed purchase decision.

How to Choose the Best Metal Milling Machine for Your Needs? - Budgeting and Cost Considerations for Your Milling Machine Purchase

| Feature | Description | Estimated Cost (USD) | Recommended Use |

|---|---|---|---|

| Type of Milling Machine | Vertical or Horizontal | $2,000 - $10,000 | General machining tasks |

| Bed Size | Length x Width of the working area | $1,500 - $6,000 | Larger projects and parts |

| Motor Power | Higher power allows for more robust cutting | $1,000 - $3,500 | Heavy-duty applications |

| CNC Capability | Computer Numerical Control for automation | $5,000 - $30,000 | Precision machining and mass production |

| Accessories and Tooling | Collets, drills, and end mills | $300 - $2,000 | Customizing machine capabilities |

Related Posts

-

Exploring Innovative Alternatives to Small Milling Machines: A Data-Driven Approach for Enhanced Precision

-

Maximizing Your Investment: How Post-Sales Support and Maintenance Costs Impact Desktop Milling Machine Efficiency

-

Strength from China's Leading Factory Powers Global Trust in Innovative Small Milling Machines

-

Setting the Benchmark: Global Standards and Innovations in Metal Milling Machine Production

-

Precision CNC Machining vs Traditional Manufacturing A Comprehensive Analysis of Efficiency and Cost Effectiveness

-

7 Reasons Why Investing in the Best Horizontal Machining Center Elevates Manufacturing Efficiency