Unlocking Precision: Tips to Choose the Right Desktop CNC Lathe for Your Manufacturing Needs

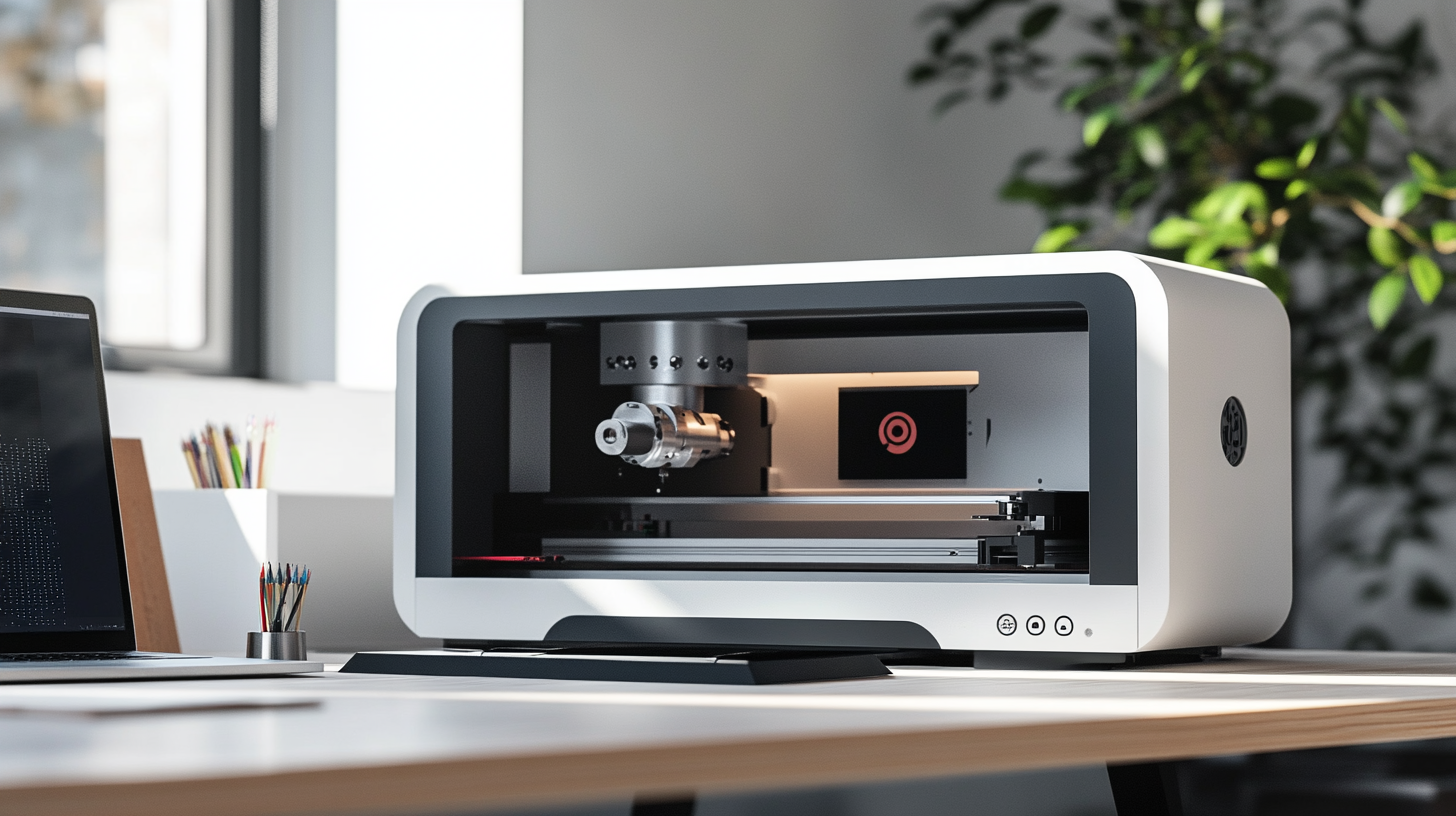

In the rapidly evolving landscape of manufacturing, the need for precision and efficiency is at an all-time high. For hobbyists and professionals alike, a Desktop CNC Lathe offers an incredible opportunity to enhance creativity and streamline production processes. However, selecting the right desktop CNC lathe can be a daunting task, given the myriad of options available on the market. Understanding your specific manufacturing needs and the capabilities of different CNC lathes is essential for making an informed decision.

As technology continues to advance, the features and functionalities of desktop CNC lathes have diversified, catering to various applications, from intricate designs to bulk production. This blog aims to provide valuable insights and practical tips for choosing the perfect desktop CNC lathe that aligns with your requirements. Whether you are a seasoned machinist or just starting your journey in CNC machining, the information provided here will guide you in unlocking the precision and efficiency you seek in your manufacturing endeavors.

Key Factors to Consider When Selecting a Desktop CNC Lathe

When selecting a desktop CNC lathe, there are several key factors to consider that can significantly impact your manufacturing outcomes. Firstly, assess the machine’s precision capabilities. Look for lathes that offer tight tolerance controls and high-resolution outputs, as these features are crucial for achieving intricate designs and maintaining consistency across projects. A machine with advanced positioning accuracy will allow for more complex shapes and detailed work, making it suitable for a variety of applications. Another factor to evaluate is the lathe's build quality and durability. Machines constructed from robust materials tend to withstand the rigors of production better, ensuring longevity and minimal maintenance. Additionally, consider the ease of use and software compatibility. A user-friendly interface, along with support for popular CAD/CAM software, will enhance your productivity and allow for seamless integration into existing workflows. Lastly, don’t overlook the importance of customer support and availability of spare parts from the manufacturer. A responsive support team can be invaluable, especially when unexpected issues arise. By taking these factors into account, you can make an informed decision when choosing the right desktop CNC lathe that aligns with your specific manufacturing needs, ultimately driving efficiency and precision in your projects.

Understanding Different Types of CNC Lathes and Their Applications

When selecting a desktop CNC lathe, it’s essential to understand the different types available and their unique applications. CNC (Computer Numerical Control) lathes can generally be categorized into two main types: the traditional CNC lathe and the more advanced multi-axis CNC lathe. Traditional CNC lathes are primarily designed for straightforward turning operations, where cylindrical parts are shaped efficiently. They are ideal for manufacturers focusing on simple production runs, such as creating shafts, tubes, and other symmetrical components.

On the other hand, multi-axis CNC lathes offer greater versatility, allowing for more complex machining operations. Typically, these lathes include additional axes of movement, which enable the production of intricate geometries and parts that require more than just turning. This makes them suitable for applications in industries like aerospace and medical device manufacturing, where precision and complexity are crucial. By understanding these distinctions, manufacturers can better assess which type of CNC lathe aligns with their specific production needs and technical requirements.

Additionally, factors such as workpiece size, material type, and desired tolerances should inform the decision-making process. Smaller desktop CNC lathes are often capable of handling a range of materials, from plastics to metal, making them a valuable asset for prototyping and small-scale production. Ultimately, integrating the right CNC lathe into your operations can lead to enhanced productivity, improved product quality, and the ability to innovate in design and manufacturing.

Evaluating Precision and Tolerance for Your Manufacturing Projects

When selecting a desktop CNC lathe for your manufacturing needs, evaluating precision and tolerance is crucial. Precision in CNC machining directly impacts the quality of your projects, ensuring that each component meets the exact specifications required for effective functionality. This aspect involves understanding the uncertainty inherent in your measurement systems, as noted in recent discussions on measurement accuracy. Choosing a CNC lathe with high repeatability precision will minimize variances in production, leading to efficient workflows and reduced waste.

Different manufacturing processes utilize various parameters to achieve desired tolerances. For example, in wire arc additive manufacturing, the coordination of process parameters plays a significant role in shaping and evaluating the final product. Similarly, in conventional CNC operations, factors such as cutting speed, feed rate, and material properties can influence the level of precision achievable. Comprehensive evaluation of these parameters is essential to ensure that your CNC lathe can consistently produce parts with the necessary dimensional accuracy and surface finish.

Furthermore, advancements in methodologies like the Ishikawa diagram promote a deeper understanding of quality assessment and error analysis in manufacturing. By integrating these insights into your decision-making process, you can effectively select a CNC lathe that aligns with your project goals, enhancing production quality and maintaining high tolerance levels throughout the manufacturing lifecycle.

Budgeting Wisely: Cost vs. Features in Desktop CNC Lathes

When considering a desktop CNC lathe for your manufacturing needs, understanding the balance between cost and features is crucial. Budget constraints are common in any project, but the cheapest option may not always fulfill your requirements. It’s essential to evaluate what features are critical for your work. For instance, if precision is a top priority, investing in a higher-quality machine with advanced tooling options may save you money in the long run by reducing waste and rework.

Another vital aspect to keep in mind is the perceived value of added features. Many desktop CNC lathes come with impressive specifications—such as higher spindle speeds, larger work envelopes, and enhanced control systems. While these might increase the initial cost, they can also significantly improve efficiency and output quality, ultimately leading to greater profitability. Therefore, take a closer look at how these features align with your manufacturing goals; an upfront investment could yield better returns than a cost-saving compromise on quality.

Finally, don't overlook the importance of support and service associated with your chosen CNC lathe. A machine that's a bit more expensive but comes with robust customer support, training resources, and warranty coverage may be worth considering. As you weigh your options, remember that the right desktop CNC lathe should not only fit your budget but also effectively meet your operational needs, ensuring that your business thrives in a competitive market.

Maintenance and Support: Ensuring Longevity of Your Equipment

When investing in a desktop CNC lathe, it's crucial to consider not just the initial purchase but also the long-term maintenance and support. Regular maintenance is key to ensuring the longevity and precision of your equipment. This includes routine checks on moving parts, lubrication of bearings, and calibration of the machine to keep it operating at peak performance. A well-maintained CNC lathe can significantly reduce the risk of unexpected breakdowns, which can be costly in terms of both time and resources.

Creating a maintenance schedule is an effective way to keep track of necessary upkeep for your CNC lathe. This might include weekly checks for wear and tear, monthly cleaning sessions, and annual professional servicing. Additionally, it’s beneficial to keep spare parts readily available, so you’re prepared for any minor repairs that could arise. Understanding your machine's service requirements enables you to anticipate issues before they escalate, ensuring a smoother operation and minimal downtime.

Another essential aspect of maintenance is having access to support and resources. Many manufacturers offer support packages that include troubleshooting guides, online forums, and direct contact with technical experts. Building a relationship with your equipment supplier can also facilitate quicker repairs and more personalized advice when needed. By prioritizing maintenance and support, you not only prolong the life of your CNC lathe but also enhance your overall productivity and efficiency in manufacturing.