What is Cnc Machining Parts and How They Transform Modern Manufacturing

In the ever-evolving landscape of modern manufacturing, CNC machining parts have emerged as a cornerstone of precision engineering and efficiency. According to a report by MarketsandMarkets, the global CNC machining market is projected to reach approximately $100 billion by 2025, driven by the increasing demand for highly accurate and complex components across various industries. These parts, produced through a computer-controlled subtractive manufacturing process, not only enhance productivity but also significantly reduce production time and waste. As businesses strive to stay competitive, the integration of CNC machining parts into their production processes is no longer optional but a necessity. This blog explores the definitions, applications, and transformative impact of CNC machining parts on modern manufacturing, highlighting how this technology continues to shape the future of industrial operations.

Understanding CNC Machining Parts: The Backbone of Industrial Innovation

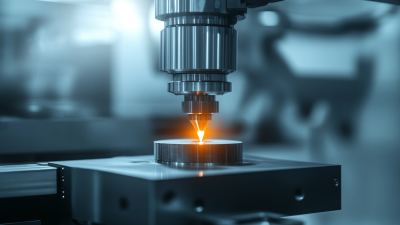

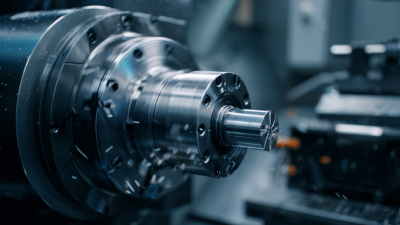

CNC machining parts serve as the backbone of industrial innovation, revolutionizing the way manufacturers create precision components. This technology utilizes computer numerical control to automate the machining process, allowing for high levels of accuracy and repeatability. By converting digital designs into tangible products, CNC machining eliminates the human error inherent in manual operations, ensuring that parts meet stringent specifications. This reliability has made CNC machining an indispensable process in numerous industries, from aerospace to automotive.

The versatility of CNC machining parts plays a crucial role in advancing modern manufacturing. With the ability to work with a wide range of materials, including metals, plastics, and composites, CNC machines can produce intricate designs that were previously impossible or cost-prohibitive. Additionally, the integration of CAD (Computer-Aided Design) software into the CNC process enables rapid prototyping and reduces lead times, allowing companies to innovate faster and respond promptly to market demands. As industries continue to embrace digital technologies, CNC machining will remain central to their growth, driving efficiency and fostering creativity in product development.

Understanding CNC Machining Parts: Production Volume by Material Type (2023)

Key Benefits of CNC Machining in Modern Manufacturing Processes

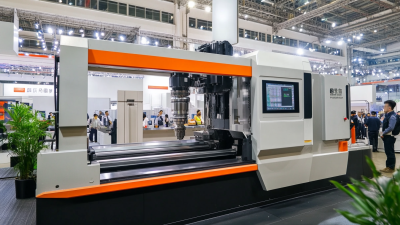

CNC machining has become a cornerstone of modern manufacturing, offering numerous benefits that enhance production efficiency and precision. The global market for machining centers has demonstrated substantial growth, with a valuation of $29.17 billion in 2018, and a projected compound annual growth rate (CAGR) of 4.9% through 2032. This growth highlights the increasing adoption of CNC technology across various industries, as manufacturers seek to optimize their operations and meet the rising demand for high-quality, durable components.

One of the key advantages of CNC machining is its ability to produce intricate parts with high accuracy and repeatability. This capability significantly reduces the margin of error that is often associated with traditional manufacturing methods. Moreover, the integration of digital manufacturing technologies is proving essential in increasing productivity, particularly in the context of Industry 4.0. As manufacturers continue to embrace automated solutions and environmentally friendly machinery, the CNC market is set to expand further, with projections indicating a growth from $14.34 billion in 2025 to $21.69 billion by 2033, at a CAGR of 5.7%. This trend underscores the critical role CNC machining plays in transforming modern manufacturing processes and meeting the evolving needs of the market.

What is Cnc Machining Parts and How They Transform Modern Manufacturing - Key Benefits of CNC Machining in Modern Manufacturing Processes

| Dimension | Details |

|---|---|

| Precision | CNC machining achieves tolerances within ±0.001 inches, ensuring high precision for complex parts. |

| Efficiency | Automated processes allow for high-volume production at faster speeds compared to traditional machining. |

| Material Versatility | CNC machining can work with a wide range of materials including metals, plastics, and composites. |

| Reduction of Waste | CNC machining optimizes material usage, thereby minimizing waste during the manufacturing process. |

| Customization | Rapid prototyping capabilities allow manufacturers to create custom parts efficiently. |

| Consistency | CNC machines ensure consistent quality across large production runs, reducing human error. |

| Safety | Automated processes increase workplace safety by minimizing operator involvement in hazardous environments. |

The CNC Machining Workflow: From Design to Production

The CNC machining workflow is a systematic process that bridges the gap between design and production, playing a pivotal role in modern manufacturing. It all begins with creating a precise computer-aided design (CAD) model. Designers utilize advanced software to conceptualize parts, taking into account specifications such as dimensions, tolerances, and materials. This stage is critical because a well-thought-out design ensures that the final product meets quality and functional requirements.

Once the CAD model is complete, it is translated into a machine-readable format, typically through computer-aided manufacturing (CAM) software. This process involves generating toolpaths that guide the CNC machines during production. With the program set, the CNC machine cuts, mills, or drills the material with high accuracy, producing parts at an impressive speed. The workflow includes careful monitoring and quality checks at various stages to ensure that the finished components match the original design. By integrating these advanced technologies, CNC machining significantly enhances efficiency, reduces waste, and allows for complex geometries that traditional manufacturing methods cannot achieve.

Common Materials Used in CNC Machining and Their Applications

CNC machining has revolutionized modern manufacturing by offering precision, efficiency, and versatility in producing components across various industries. Common materials used in CNC machining include aluminum, steel, and plastics, each chosen based on their unique properties and the specific requirements of the application. Aluminum, for instance, is favored for its lightweight nature and excellent corrosion resistance, making it ideal for electronics and automotive parts. Steel, with its strength and durability, is often used in applications where high tensile strength is required, such as aerospace components.

CNC machining has revolutionized modern manufacturing by offering precision, efficiency, and versatility in producing components across various industries. Common materials used in CNC machining include aluminum, steel, and plastics, each chosen based on their unique properties and the specific requirements of the application. Aluminum, for instance, is favored for its lightweight nature and excellent corrosion resistance, making it ideal for electronics and automotive parts. Steel, with its strength and durability, is often used in applications where high tensile strength is required, such as aerospace components.

Another popular material is plastic, which provides flexibility and can be molded into complex shapes. This versatility allows manufacturers to produce custom parts quickly and cost-effectively. The growth of the CNC machining market, projected to reach over 432.5 billion yuan in 2024, highlights the increasing demand for precision-engineered components. As industries continue to evolve, the selection of materials and their applications will play a crucial role in enhancing manufacturing processes and improving product performance.

Future Trends in CNC Machining: What to Expect in Manufacturing Technology

As we look towards the future of CNC machining, we can anticipate significant advancements that will reshape the landscape of manufacturing technology. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach $100 billion by 2025, growing at a CAGR of 7.5%. This growth is driven by the increasing demand for precision parts and the rise of automation in production processes. Industries are increasingly leveraging CNC machining for its accuracy, efficiency, and ability to reduce human error, which is becoming paramount in meeting the qualitative demands of modern manufacturing.

Emerging technologies, such as Artificial Intelligence (AI) and the Internet of Things (IoT), are set to revolutionize CNC machining. The integration of AI in CNC systems can enhance predictive maintenance, optimize machining processes in real time, and lead to improved overall equipment effectiveness. Likewise, IoT connectivity enables machines to communicate and share data, leading to smarter factories and quicker responses to production anomalies. As reported by Deloitte, the smart manufacturing market could exceed $500 billion by 2025, hinting at a promising future where CNC machining forms the backbone of intelligent manufacturing systems, driving efficiency and innovation in ways that were previously unimaginable.

Related Posts

-

Ultimate Guide to Sourcing the Best CNC Precision Parts: Key Insights and Industry Trends

-

Essential Guide: 10 Key Features to Evaluate When Choosing an Industrial CNC Machine

-

Built on Trust Best Axis Cnc from a Leading Chinese Factory

-

Choosing the Right Manufacturer for Your Best Axis CNC Needs

-

Exploring the Versatile Features and Applications of the Best CNC Machines for Global Buyers

-

Exploring Opportunities for Multi Axis CNC Machine at the Successful 137th China Import and Export Fair