Digital Insights into the Best CNC Precision Techniques for 2023

In 2023, the landscape of manufacturing continues to evolve, with CNC precision standing at the forefront of this transformation. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach $100 billion by 2026, reflecting a compound annual growth rate (CAGR) of 6.5% from 2021. This surge underscores the increasing demand for high-precision machinery in various industries, from aerospace to automotive. As businesses strive to enhance efficiency and reduce costs, mastering CNC precision techniques is paramount. This blog will delve into the latest digital insights and best practices for optimizing CNC precision, ensuring manufacturers stay competitive in an ever-changing market. Whether you are a seasoned professional or just starting in the field, understanding these techniques will be crucial for leveraging the full potential of CNC technology.

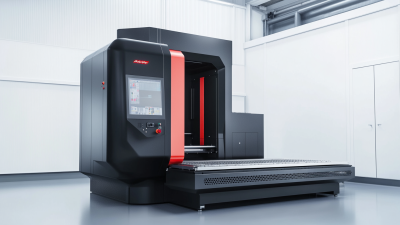

Innovative CNC Precision Techniques Transforming the Manufacturing Landscape in 2023

The manufacturing landscape is evolving rapidly in 2023, with innovative CNC precision techniques leading the charge. These advancements not only enhance productivity but also allow for unprecedented levels of customization and efficiency. As industries adopt digital manufacturing technologies, they are witnessing significant changes that streamline operations and reduce waste, positioning themselves for success in a competitive market.

One critical tip for manufacturers is to invest in integrating artificial intelligence with CNC machines. This combination enables real-time analysis of production processes, allowing for immediate adjustments and minimizing errors. Additionally, leveraging additive manufacturing techniques can enhance design flexibility and material use, making it easier to meet specific industry demands while supporting sustainability efforts.

Another vital consideration is the importance of upskilling employees to handle advanced manufacturing tools. With the industry's shift towards automation and precision, organizations should focus on training their workforce in these new technologies. Emphasizing ongoing education not only boosts productivity but also fosters a culture of innovation that is essential for thriving in the advanced manufacturing sector.

Top Challenges Faced by CNC Operators in Achieving Precision and Efficiency

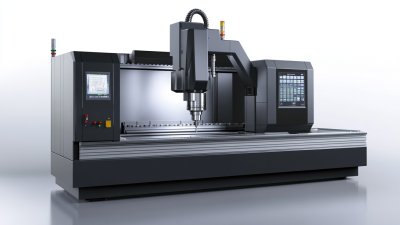

Achieving precision and efficiency in CNC operations is increasingly challenging, especially as the industry adapts to new technologies and rising demands. CNC operators often encounter issues related to maintaining accuracy while optimizing production speed. Factors such as tool wear, machine calibration, and environmental influences can significantly impact the final output quality. As the market projected to grow significantly, operators must tackle these challenges head-on to stay competitive.

Tips for enhancing CNC precision include implementing in-process monitoring strategies. By continuously measuring key parameters such as force and temperature during machining, operators can make real-time adjustments that ensure better accuracy. Additionally, adopting advanced robotic milling techniques can lead to higher precision in complex parts. Operators should also focus on improving their machining process planning and trajectory optimization to mitigate vibration issues, ultimately enhancing overall efficiency.

Moreover, investing in innovative calibration technologies, such as nozzle aligners, can drastically improve the precision of laser cutting processes. These advancements not only streamline operations but also help to address common calibration challenges that arise in CNC machining environments. By embracing these strategic approaches, CNC operators can elevate their precision, ultimately leading to greater productivity and profitability in a rapidly evolving market.

Impact of Advanced Materials on CNC Machining Precision in the Current Industry

The advent of advanced materials is significantly influencing CNC machining precision, enhancing capability while reducing operational costs. As industries increasingly adopt 5-axis CNC machining, the integration of materials like titanium and high-performance polymers is allowing for intricate designs and greater geometrical precision. These materials not only enhance the durability of the machined components but also improve the overall efficiency of machining processes. The shift towards self-optimized machine cutting techniques further complements this trend, leveraging data and analytics to ensure optimal performance and precision.

Moreover, the role of nanotechnology is becoming increasingly prominent in modern CNC machining, enabling manufacturers to discover and utilize new materials that meet stringent precision requirements. By employing advanced manufacturing techniques alongside digital twin technology, companies can simulate real-world conditions, allowing for proactive adjustment and refinement during the machining process. This synergy between innovative materials and intelligent manufacturing solutions paves the way for unprecedented levels of accuracy and productivity in CNC operations, reflecting the dynamic landscape of the current industry.

Statistical Analysis of CNC Machine Performance: What the Data Reveals for 2023

In 2023, the realm of CNC machining has made significant strides, and statistical analysis has become integral in revealing machine performance nuances. By meticulously analyzing data from various CNC machines, manufacturers can identify trends in efficiency, accuracy, and operational downtime. Metrics such as feed rate, spindle speed, and tool wear contribute to a comprehensive understanding of performance, enabling operators to optimize processes and reduce waste.

Moreover, the implementation of advanced analytics tools allows for real-time monitoring and predictive maintenance, ensuring machines operate at peak efficiency. As we delve deeper into the data, it becomes clear that specific techniques, such as adaptive machining and intelligent tool management, emerge as frontrunners in enhancing precision. Armed with insights from performance data, manufacturers can make informed decisions to invest in technology and training, pushing the boundaries of what is achievable in CNC precision machining. The future of CNC lies in leveraging data-driven insights for continuous improvement and innovation.

Emerging Technologies Shaping the Future of CNC Precision Machining

The landscape of CNC precision machining is being profoundly shaped by emerging technologies such as artificial intelligence (AI) and the Internet of Things (IoT). A recent industry report highlights that businesses integrating these technologies have seen productivity increases of up to 30%. This digital transformation not only streamlines operations but also enhances the precision of machine tools, allowing for more complex and intricate designs to be executed with minimal errors.

Moreover, the shift towards automation in the manufacturing sector, particularly in regions like Dongguan, is indicative of a global trend. Leading CNC equipment manufacturers are expanding their production capabilities, with facilities now boasting advanced robotics that can operate seamlessly in conjunction with human workers. This evolution is pivotal for maintaining competitiveness in an era where speed and quality are paramount.

Research suggests that by 2025, companies that successfully leverage these innovations could realize operational efficiencies of 40% or more, redefining what’s possible in precision machining.

Related Posts

-

Discover the Competitive Edge of Axis Cnc for Your Global Manufacturing Needs

-

Exploring the Versatile Features and Applications of the Best CNC Machines for Global Buyers

-

Optimizing Maintenance Costs and Enhancing After Sales Support for Cnc Precision Parts

-

Evaluating CNC Parts: Key Factors That Distinguish Quality Suppliers

-

Unlocking Efficiency in Global Procurement: Mastering CNC Turning Techniques for Optimal Sourcing

-

Finding Reliable Suppliers for Your Cnc Machine Tools Needs