Future Trends in CNC Turning Machines and Global Market Comparisons for 2025

The landscape of manufacturing technology is evolving rapidly, with CNC turning machines at the forefront of this transformation. As industries increasingly demand precision and efficiency, the global CNC turning machine market is projected to expand significantly. According to a report by Research and Markets, the CNC turning machine market is expected to reach approximately $12 billion by 2025, with a compound annual growth rate (CAGR) of over 6% from 2020 to 2025. This growth is fueled by surging demand in sectors such as automotive, aerospace, and medical, where high precision and reliability are paramount.

In addition to increased production capabilities, advancements in automation and artificial intelligence are set to redefine the operational efficiency of CNC turning machines. Industry experts predict that by 2025, more than 40% of turning machines will be equipped with smart technology for data analytics and predictive maintenance. A report by Market Research Future highlights how such innovations will not only enhance productivity but also reduce downtime, thereby enabling manufacturers to better meet the evolving needs of the global market. As we delve deeper into the future trends of CNC turning machines, understanding these dynamics will offer valuable insights into strategic planning for stakeholders across the industry.

Emerging Technologies Shaping the Future of CNC Turning Machines

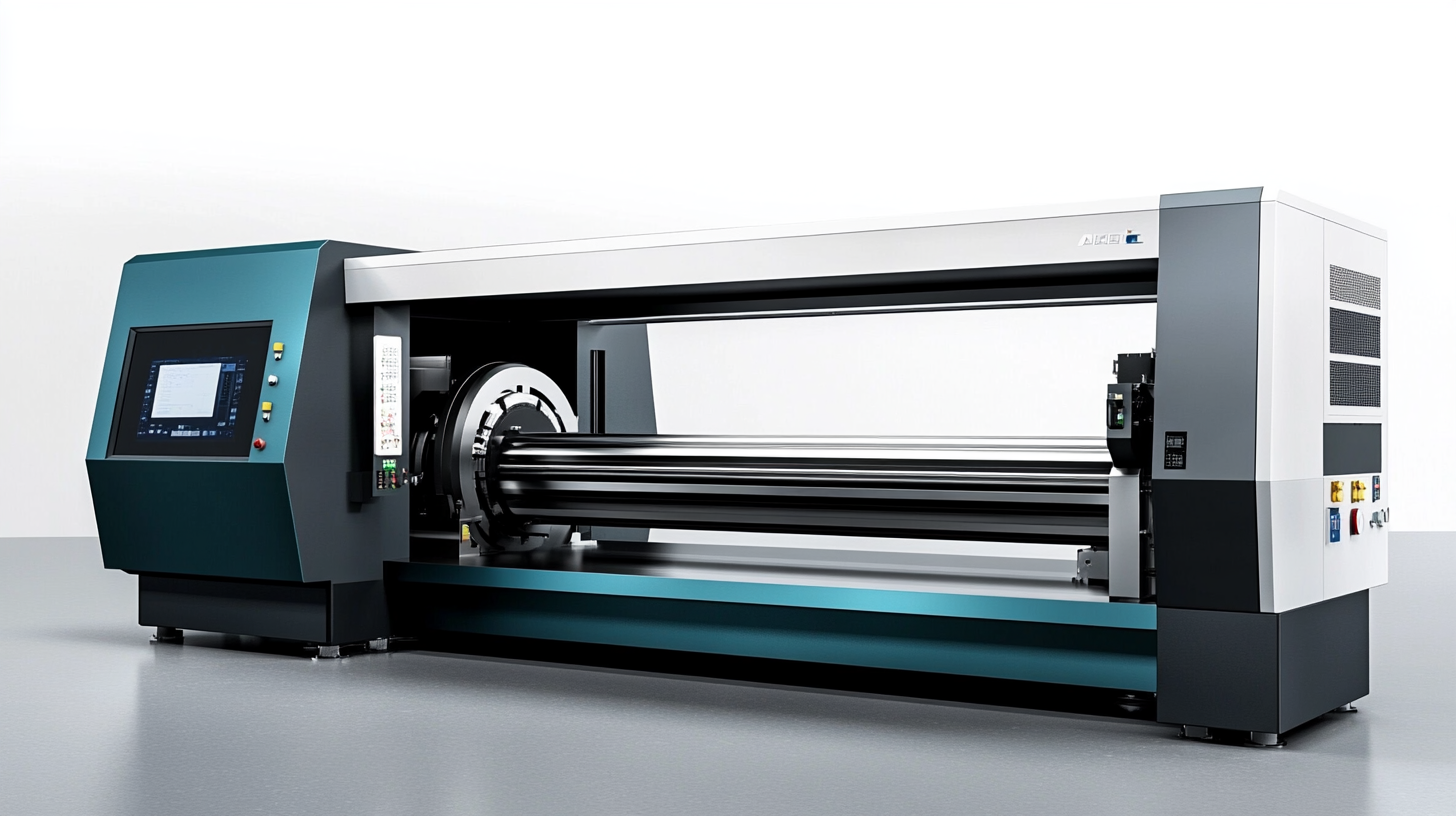

The landscape of CNC turning machines is set to undergo significant transformation by 2025, driven by emerging technologies that promise to enhance precision, efficiency, and automation. One of the most pivotal trends is the integration of advanced robotics in CNC turning processes. These robots not only streamline operations but also increase productivity by handling complex tasks that were previously time-consuming or prone to human error. As manufacturers increasingly adopt automation, the demand for skilled labor is shifting towards machine programming and maintenance, reshaping workforce requirements in the industry. Another influential factor is the rise of Industry 4.0 and the Internet of Things (IoT). Smart CNC machines equipped with sensors and real-time data analytics can monitor performance and predict maintenance needs, minimizing downtime and optimizing production. This data-driven approach fosters greater flexibility in manufacturing, allowing companies to tailor their output to specific market demands swiftly. In addition, the development of cloud computing platforms enables enhanced collaboration and resource sharing among manufacturers globally, fostering innovation and competitiveness. Moreover, advancements in materials technology are playing a crucial role in the evolution of CNC turning machines. The ability to machine new composite materials and lightweight alloys not only elevates the performance standards of end products but also reduces waste and energy consumption during production. As sustainability becomes a central concern across various industries, CNC turning machines will adapt to meet these new standards, aligning with global initiatives aimed at reducing environmental impact. The adoption of these emerging technologies is set to redefine the operational capabilities of CNC turning machines, marking a pivotal shift in manufacturing practices in the years to come.

Key Market Players and Competitive Landscape in CNC Turning for 2025

The CNC turning machine market is poised for significant expansion as we approach 2025, with a notable shift in the competitive landscape. Key market players are increasingly investing in advanced technologies and automation capabilities to enhance their offerings. This trend reflects a broader industry move towards precision engineering, which not only boosts efficiency but also helps manufacturers meet the rising demand for high-quality, customized products. Companies that leverage automation and digital solutions are likely to gain a competitive edge, allowing them to respond swiftly to market changes.

As the CNC machine market is projected to grow from $101.22 billion in 2025 to $195.59 billion by 2032, the role of strategic partnerships and collaborations cannot be overlooked. Key players in the industry are focusing on developing alliances that enhance their technical expertise and market reach. By integrating innovative technologies, such as IoT and AI, these companies are set to redefine manufacturing processes, making them more adaptive and user-friendly.

Moreover, the global lathe machines market is experiencing a surge due to increased automation and a demand for precision engineering. This shift signals a promising future for manufacturers willing to innovate. As market dynamics evolve, it will be critical for industry participants to monitor growth trends and seize emerging opportunities to maintain a strong competitive position in the marketplace.

Global Market Trends: Growth Drivers and Challenges in CNC Turning Machines

The global CNC (Computer Numerical Control) machines market is poised for significant growth, projected to expand from approximately $101.22 billion in 2025 to $195.59 billion by 2032, reflecting a robust CAGR of 9.9%. This upward trajectory can be attributed to several growth drivers, including rising demand for automation in manufacturing and advancements in AI technology, which are enhancing machining capabilities and precision. However, high installation and maintenance costs remain considerable challenges that could impede overall market potential.

Moreover, the CNC machining and turning centers market is estimated at $25.99 billion in 2023, with expectations of a 6.6% CAGR from 2024 to 2030. This growth is driven by increasing applications in various industries such as aerospace, automotive, and healthcare, where precision and efficiency are paramount. Importance is being placed on innovation, with special emphasis being placed on 5-axis CNC machining centers that utilize self-optimized cutting processes to deliver superior results.

As we move toward 2025, the competitive landscape of the CNC machines market will increasingly hinge on the ability of manufacturers to integrate cutting-edge technologies and streamline operational efficiencies. The synergy between machine design and intelligent automation will likely become a defining trend, influencing investment and production strategies across the sector.

Regional Analysis: CNC Turning Machine Adoption Across Different Markets

The global CNC turning machine market is expected to see significant growth through 2025, driven by advancements in manufacturing automation and an increasing demand for precision in production processes. As industries around the world strive to enhance efficiency and product quality, regions such as North America, Europe, and Asia-Pacific are witnessing varying rates of CNC turning machine adoption. This divergence can be attributed to factors like technological readiness, workforce skills, and the economic landscape unique to each area.

In North America, particularly the U.S., the adoption of CNC technology is robust, spurred by widespread use in aerospace, automotive, and medical device manufacturing. Companies are investing heavily in automation to maintain competitive advantage, resulting in a surge in demand for sophisticated CNC turning machines. Meanwhile, Europe reflects a similar trend, with countries like Germany leading the way in high-precision engineering and innovation in CNC machining. The ongoing push for sustainability and integration of smart manufacturing concepts further accelerates the adoption of these advanced machine tools.

Conversely, in Asia-Pacific, the market is characterized by rapid industrialization and a growing manufacturing base. Countries like China and India are quickly adopting CNC turning machines to meet the growing demands of both local and export markets. The region's focus on enhancing production capabilities and improving efficiency in manufacturing processes signifies a significant opportunity for growth. By 2032, the market for CNC machines in Asia-Pacific is projected to match or even exceed that of its Western counterparts, showcasing the global shift towards embracing automation and precision engineering on a broader scale.

Sustainability in CNC Manufacturing: Eco-Friendly Innovations and Practices

As the CNC manufacturing industry looks toward the future, the focus on sustainability is becoming increasingly prominent. Innovations in eco-friendly practices are shifting the landscape of CNC turning machines, making them not only more efficient but also significantly reducing their environmental footprint. This trend aligns with a broader global movement toward sustainable manufacturing, where companies are exploring technologies and methods that promote resource conservation and waste reduction.

China's Genghai No. 1 marine ranching project exemplifies the potential of integrating high-tech solutions into sustainability efforts. By restoring marine ecosystems and promoting responsible resource management, this initiative offers insights into how industries can harmonize their operations with environmental stewardship. Similar approaches in CNC machining can involve the adoption of advanced materials, energy-efficient processes, and recycling practices, ultimately contributing to the preservation of natural resources.

In the CNC sector, eco-friendly innovations like water-based coolants and energy-efficient motors are paving the way for greener manufacturing practices. The integration of IoT and AI technologies can further enhance operational efficiency, allowing manufacturers to monitor and optimize their processes in real time, thereby minimizing waste. As we advance toward 2025, the synergy between sustainability and technological advancement will not only reshape CNC turning machines but will also catalyze a more responsible manufacturing industry on a global scale.