What is a Cooling Tower and How Does It Work?

cooling towers play a crucial role in various industries. According to Dr. Emily Schneider, a leading expert in thermal systems, “Cooling towers are essential for efficient heat management.” This statement highlights their importance in modern engineering.

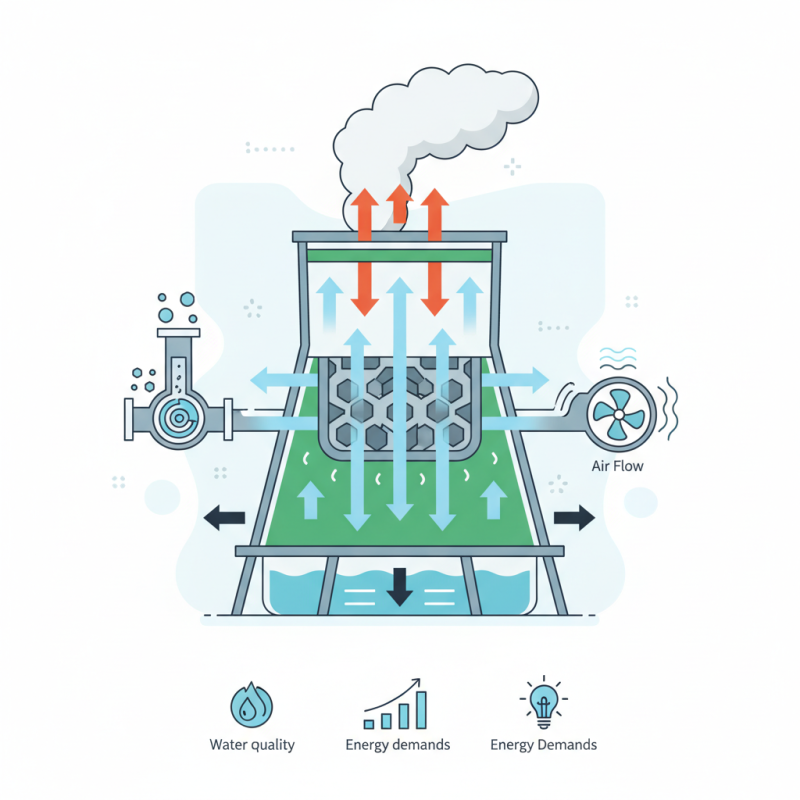

A cooling tower functions by rejecting heat from water. This process allows warm water to cool down before it cycles back into industrial systems. However, designing a cooling tower isn't straightforward. Factors like water quality and air flow can affect performance.

Moreover, despite advancements in technology, challenges remain. Many cooling towers face issues with scaling and maintenance. Addressing these concerns is vital for ensuring efficiency. In a world where energy demands are rising, understanding cooling towers is more important than ever.

What is a Cooling Tower?

Cooling towers play a crucial role in industrial and commercial facilities. They are essential for dissipating excess heat from water used in cooling systems. The basic principle involves transferring heat from the water to the air, often through evaporation. According to the U.S. Department of Energy, cooling towers can reduce energy consumption by up to 30% in large facilities, making them vital for efficiency.

The design of a cooling tower can vary significantly. Some are open cooling towers that rely on natural draft to move air through them. Others are closed circuit towers that circulate water in closed loops. Each has advantages and disadvantages. For example, open cooling towers are more efficient but require more maintenance. In contrast, closed cooling towers may be more straightforward to maintain but can be less efficient.

Despite their efficiency, cooling towers are also sources of potential issues, such as water treatment needs and bacteria growth. The CDC highlights that Legionella, a harmful bacteria, can thrive in poorly maintained towers. Regular inspections and proper maintenance are essential, yet many facilities overlook these aspects. Managing a cooling tower effectively requires ongoing attention and resources.

Types of Cooling Towers and Their Applications

Cooling towers play a vital role in various industries. They help dissipate heat from water-cooled systems. There are two primary types: open-circuit and closed-circuit cooling towers. Each serves distinct needs.

Open-circuit cooling towers are commonly utilized in large facilities. They expose water to ambient air, allowing evaporation to cool it down. Reports show that these towers can achieve cooling efficiencies of about 70% under optimal conditions. However, they are prone to water loss and require regular maintenance to prevent scaling and biological growth.

Closed-circuit cooling towers, on the other hand, recirculate water without contact with outside air. This design reduces evaporation losses. According to industry studies, they can save up to 30% more water than open systems. Although they are more efficient, initial costs are higher. Operators often face challenges with fouling and heat transfer efficiency. Balancing these factors is crucial for effective cooling tower operation. Managing these complexities can lead to optimized performance and reduced energy consumption.

Cooling Tower Types and Their Applications

This chart shows the number of applications (in thousands) for different types of cooling towers. Open circuit cooling towers are the most widely used, followed by closed circuit, dry cooling, and hybrid cooling systems.

How Cooling Towers Operate: The Basic Principles

Cooling towers are vital components in large-scale cooling systems. They help regulate temperatures in industrial processes. Understanding how they operate is crucial.

Cooling towers function based on evaporative cooling principles. Warm water flows from a facility into the tower. As it descends through fill material, the water spreads out, increasing surface area. Air is drawn in from the bottom. This interaction allows some water to evaporate, taking away heat. The cooler water collects at the bottom and is recirculated.

Despite their efficiency, cooling towers can face challenges. Dust and debris often accumulate, affecting airflow. Regular maintenance is necessary to keep them functioning optimally. Smaller systems may not need elaborate equipment, yet they can still struggle to remove heat effectively. Monitoring performance regularly can help identify issues early.

What is a Cooling Tower and How Does It Work? - How Cooling Towers Operate: The Basic Principles

| Dimension | Value |

|---|---|

| Cooling Capacity | 1000 Tons |

| Water Flow Rate | 8000 GPM |

| Heat Exchange Area | 1500 m² |

| Fan Power | 15 kW |

| Design Temperature Range | 5°C - 35°C |

| Expected Lifespan | 30 Years |

| Cooling Medium | Water |

Key Components of a Cooling Tower

Cooling towers are essential for thermal management in various industries. They help to dissipate unwanted heat. The main components of a cooling tower include the fill, drift eliminators, fans, and water distribution system.

Fill materials increase surface area for heat exchange. They allow water to spread, maximizing contact with air. This enhances evaporation and improves efficiency. According to industry reports, well-designed fills can increase cooling capacity by up to 30%. Drift eliminators minimize water loss. They trap water droplets, ensuring more stays in the system. Fans create airflow, essential for heat removal. Proper fan maintenance is crucial for optimal operation.

Tip: Regularly check the fill for scaling and fouling. Neglected fills can significantly reduce efficiency. Ensure that the water distribution system works effectively. Blockages can lead to uneven water flow, resulting in hot spots. Monitor the overall operation closely. Any irregularities could indicate underlying issues needing attention.

Maintenance and Efficiency Considerations for Cooling Towers

Cooling towers play a critical role in industrial systems, primarily in thermal regulation. Regular maintenance is essential to ensure optimal performance. Neglected towers can lead to efficiency losses. A study from the U.S. Department of Energy highlights that poorly maintained cooling towers can operate at 15-20% less efficiency. This inefficiency can significantly increase operational costs.

Routine inspections should include checking for scale, corrosion, and biological growth. These issues may lead to system failures. Visual checks can identify obvious debris. Data from industry standards suggest that cleaning towers can improve efficiency by up to 25%. Moreover, proper water treatment practices cannot be overlooked. They prevent build-up and extend the lifespan of the equipment.

Monitoring water usage is also critical. An inefficient cooling tower can result in excessive water loss, leading to higher expenses. Automating monitoring systems can help detect leaks or irregularities early. However, many facilities still rely on outdated methods, which is concerning. Investing in technology may seem costly, yet it often pays off in terms of energy savings and reduced water waste.