Optimizing Maintenance Costs and Enhancing After Sales Support for Cnc Precision Parts

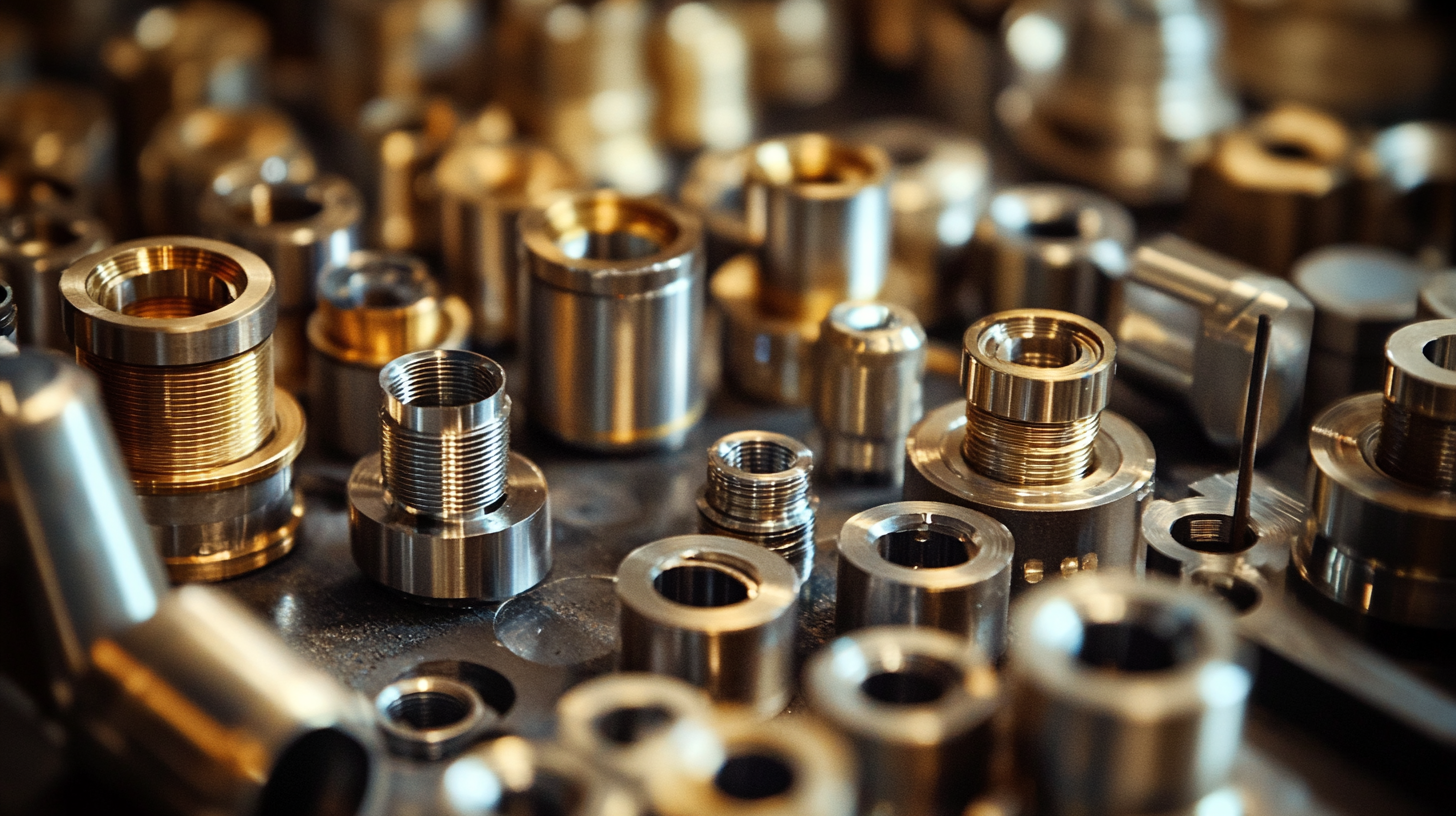

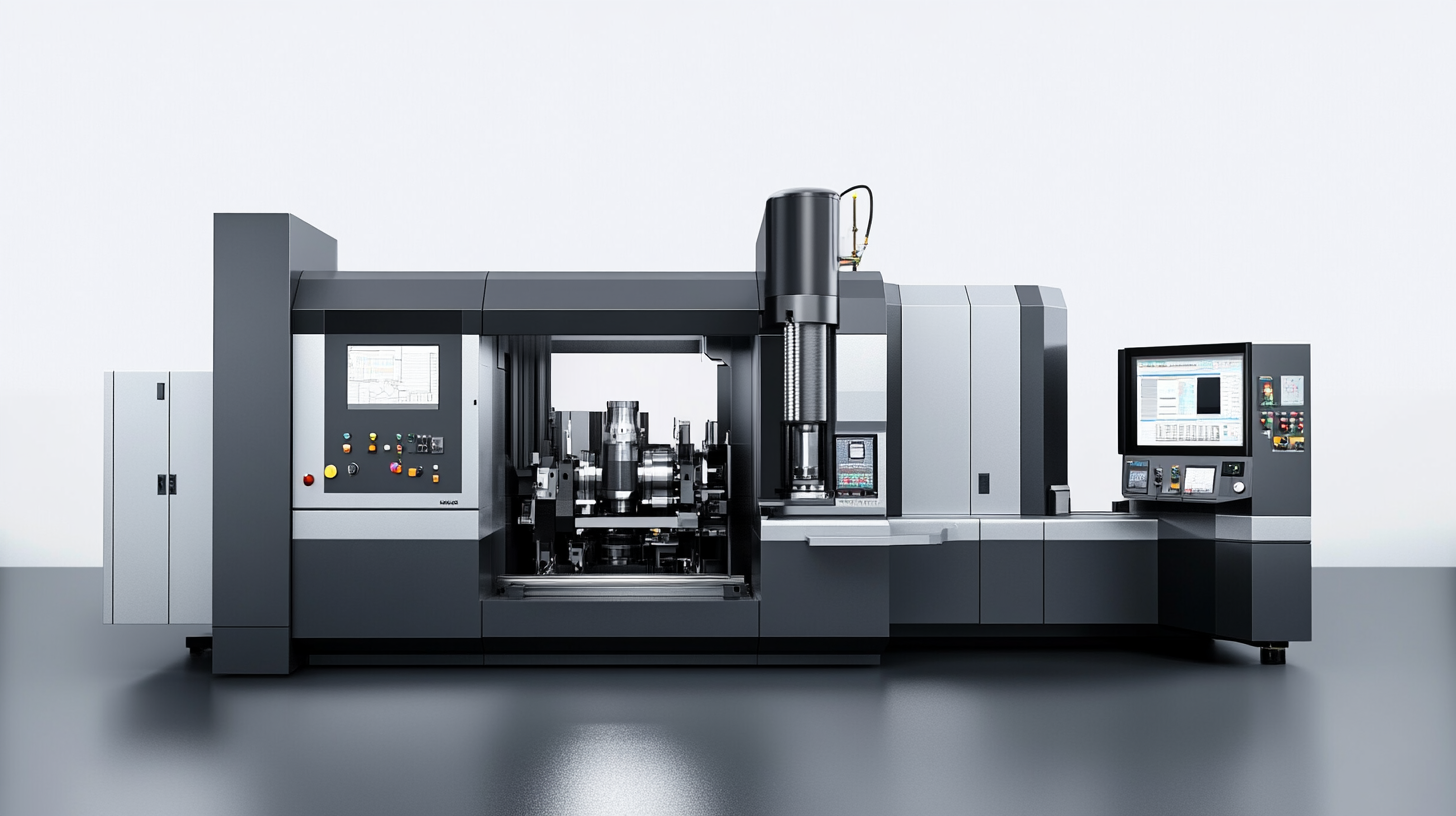

In the present manufacturing environment, very dynamic and competitive, maintenance costs management and enhancing after-sales support should be given utmost importance. One such crucial factor is the management of CNC precision parts. These components largely determine the performance of machining processes and are a considerable investment for the manufacturers. While manufacturers are doing their best to maximize production capabilities, they must seek new profitable avenues to minimize maintenance costs, thus providing better long-term support to CNC precision parts for sustained relevance.

As demand in precision engineering has increased, the issues surrounding CNC machinery maintenance and after-sales service have grown teeth. A proactive solution is needed for companies to value maintenance work so that CNC precision parts are never out of condition, thus maximizing productivity with minimal downtime. In this blog, we will examine ways to reduce maintenance costs and improve after-sales support, which should yield positive insights on how your business can utilize CNC precision parts to improve operational efficiency and customer satisfaction.

Identifying Key Maintenance Costs in CNC Precision Parts Production

It is equally important to identify the key maintenance costs associated with the production of CNC precision parts to boost operational efficiency and sustainability. Maintenance practices are acquiring the economic aspect of an operation, especially with digital transformation and automation invading the industry. Maintenance in CNC machining could be attributed to various factors-general maintenance due to slight wear and tear processes, maintenance including software updates, and interventions due to unplanned downtime. Through these analyses, manufacturers could recognize true maintenance costs, allowing them to make informed decisions regarding budgetary allocations and improvements on their equipment life. Meanwhile, automation and digital technologies are evolving CNC machining at a very fast pace. The latest trend is Industry 4.0, which promotes the introducing of cutting-edge technologies like AI and IoT into production systems. This new dimension not only increases efficiency in production operations but also raises the demand for predictive maintenance strategies. Predictive maintenance relies on data analytics to foresee equipment failures before they happen, greatly minimizing unexpected downtime and risk costs. Conversely, these innovations empower manufacturers to enrich their maintenance with more predictiveness and rapidly respond to operational concerns to keep their equipment in good working order. Furthermore, while after-sales support has been in more emphasis, it turns to be a necessity as manufacturers face increasing competition and customers' high expectations. Hence, companies must provide strong support and services to their clients. After-sales strategies are training, technical assistance, etc. To achieve maximum customer satisfaction and loyalty, after-sales services must be matched by strong technical support. By maximizing the maintenance optimization as well as after-sales support, manufacturers can leverage a distinct competitive advantage in the ever-evolving CNC precision parts industry.

Strategies for Reducing Maintenance Costs without Compromising Quality

It is a very precarious juggling act for the manufacturing sector, to maintain high-quality standards and at the same time, optimise maintenance costs. The most feasible approach is by advanced materials and data-driven technology. One such example is the recent advance in protective coatings that allowed the newly applied nano-ceramic coatings on Suzhou's wave-shaped barriers. Collectively, industries foster strength and reduce maintenance requirements. Durability is thus improved in terms of life extension for infrastructure while reducing the frequency of normal maintenance interventions, effecting notable cost savings.

It enables the manufacturers to optimize further the maintenance costs without compromising their quality by employing machine learning and data analytics. Companies are capable of predicting future failures, which leads to reduced downtime and costs of repair using predictive maintenance techniques. This would assist organizations to become more efficient in managing assets and prioritize resources appropriately. These advances reflect the value in such enterprises, whose value comes from digital transformation as enablers of upward quality change rather than cost efficiency.

Initiation of sound systems of after-sales support also becomes critical in ensuring the keeping of optimal performance. Manufacturers now need to focus on developing more comprehensive support strategies that will boost customer satisfaction and loyalty. The timely provision of maintenance solutions and linkages to cutting-edge technologies keep products at peak operational condition. This early support reduces lifetime maintenance costs while developing permanent relationships with clients, thus further driving the development of specialized and innovative enterprises in the industry.

The Role of Predictive Maintenance in CNC Equipment Longevity

Predictive maintenance is changing the way organizations think about the lifecycle costs associated with CNC equipment, ultimately leading to savings and better support after the sale. Using predictive maintenance with advanced analytics and Internet-of-Things (IoT) technologies, manufacturers can monitor conditions of equipment in real time. Before breakdown, they can usually predict or foresee the damage that can occur. As per research and markets, the predictive maintenance industry will grow by 23.5 billion dollars by the year 2023, with CNC applications among the prime beneficiaries of this trend.

Perhaps the best part of predictive maintenance is that it helps reduce unplanned downtime. According to Deloitte, this costs manufacturers around $50 billion in the US annually. However, this problem can be solved with predictive analytics, as CNC machine operators will be able to identify common patterns and deviations among machine behaviors and predict when maintenance activities should take place during non-value-adding hours to help increase equipment effectiveness (OEE). The proactive attitude is about paying maintenance visits before a given component can get bad enough to require fix failure operations.

Predictive maintenance will also help manufacturers to add extra value to their after-sales support in that it forms the basis for additional services. According to research by McKinsey, companies that now adopt predictive maintenance in their services may boost their revenues by up to 25%. Giving users actionable performance data on how best to use their machines also goes some way to building user trust, stronger relationships, and future sales. The future of the industry is very promising, and predictive maintenance will be the big thing in the optimization of maintenance costs and improvement of life for CNC precision parts.

Enhancing After Sales Support: Best Practices for Customer Engagement

Introducing after sales support in a CNC precision parts manufacturing organization can become a great strategy for engaging customers and minimizing maintenance costs. Companies with customer support frameworks in place are registering about 20% more customers retained, according to recent reports. All of these conjunction with how AI technologies facilitate more personalized dealings with customers in addition to timely responses to inquiries.

Most businesses according to latest data are employing generative AI to boost their support efforts, as it can run from one inquiry to another. Artificial Intelligence-driven chatbots and virtual assistants can handle common worries that people jump to solve while leaving the complicated ones for real humans. Moreover, one shines in findings by McKinsey that "those who apply AI in their engagements with customers should expect at least 30 percent more operational efficiency."

In addition to having immediate needs catered to by an after-sales system, it could also develop relations with customers after time. Reports have stated that highly involved customer programs can improve level of satisfaction up to 50%. Best practice use in terms like feedback loops and personalized follow-ups in after-sales communication can create a seamless experience for repeat business.

Thus, from the smallest startup to the largest, the present shaky industry is focusing on digital transformation for all types of organizations. It is about becoming part of an approx $1 trillion incremental market value across all trends of the digital economy, as companies continue to improve on AI and customer support capabilities.

Leveraging Technology to Improve Maintenance and Support Efficiency

In CNC precision parts manufacturing, technology is a critical requirement of the time that will help to bring down maintenance costs and enhance aftersales support. Advanced analytics and IoT devices are making a complete shift by changing how businesses undertake machinery upkeep and customer support. In the MarketsandMarkets report, the IoT in manufacturing global market is likely to go from $29.9 billion in 2020 to $98.9 billion by 2025, because of this urgency from the users.

One prominent benefit of technology integration is predictive maintenance, which applies machine learning algorithms to analyze performance data of machines. As per McKinsey & Company studies, it leads to 30% reduction in maintenance costs and reduced machine downtime to almost 50%. The entire paradigm shift involves anticipating problems before they materialize and scheduling interventions, not addressing issues that have already occurred.

Thus, it would also drive the after-sales service to technology-enabled channels through which manufacturers would be able to assist their customers in real time. According to a report by Salesforce, nearly 70% of customers believe brands must now understand their needs and make relevant suggestions. So, meeting these expectations while ameliorating operating costs would suffice through chatbots and AI-based customer service tools. These technologies facilitate a proactive communication strategy, ensuring customers receive timely updates and support, ultimately leading to improved customer satisfaction and loyalty in a highly dynamic market.