Finding Quality Suppliers for Best Cnc Turning Machine with Proven Strategies and Insights

In the ever-evolving landscape of manufacturing, the demand for CNC turning machines has surged, with industry analysts projecting a compound annual growth rate (CAGR) of approximately 6.2% from 2021 to 2028. This growth highlights the critical importance of sourcing quality suppliers capable of delivering high-performance CNC turning machines tailored to diverse industry needs. A reliable supplier doesn't just provide machinery; they ensure precision, efficiency, and longevity, which are essential in maintaining productivity standards in highly competitive markets. However, with numerous options available, identifying the best suppliers can be a daunting task. This blog will explore proven strategies and insights to help manufacturers navigate the complex supply chain, ensuring they invest in top-notch CNC turning machines that enhance their operational capabilities and drive business success.

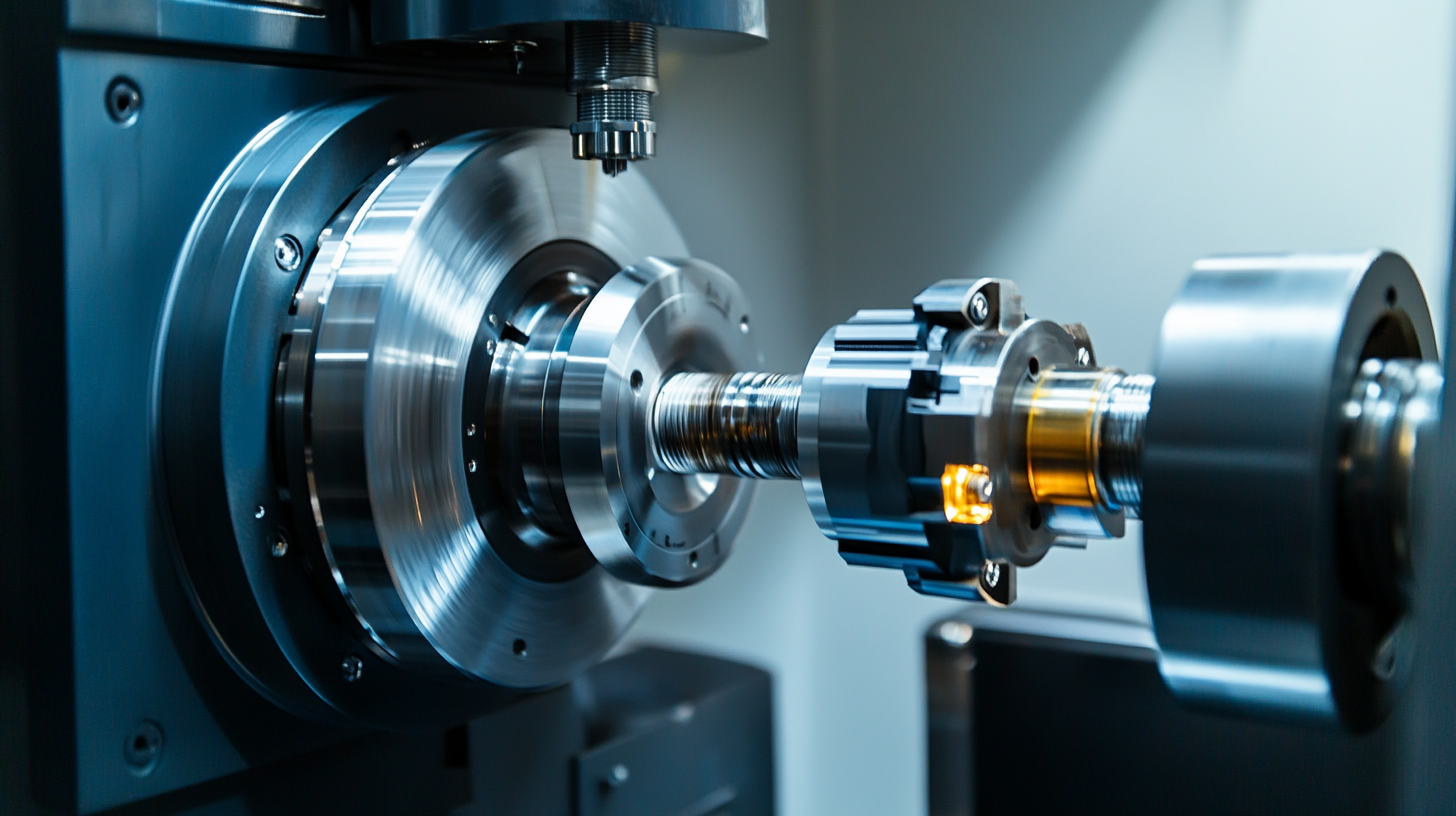

Understanding the Importance of CNC Turning Machines in Modern Manufacturing

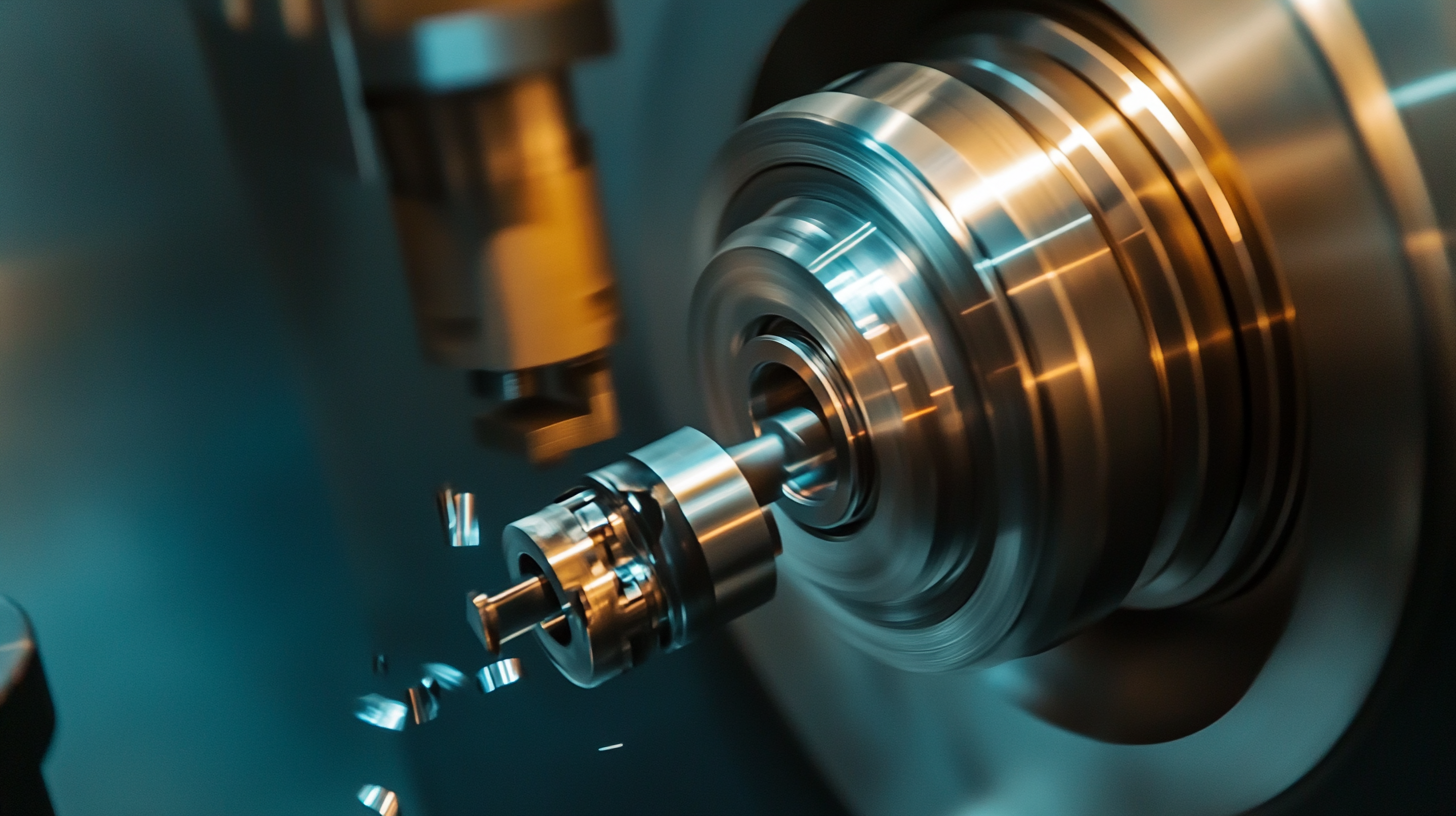

CNC turning machines play a pivotal role in modern manufacturing, offering precision and efficiency that is essential in today’s competitive landscape. These machines utilize computer numerical control to automate the cutting and shaping of materials, allowing for intricate designs and exact specifications. The ability to produce high-quality components in large volumes not only enhances productivity but also minimizes waste, making CNC turning an indispensable process for industries such as automotive, aerospace, and medical device manufacturing.

In addition to their efficiency, CNC turning machines contribute to improved product quality. With advanced technology, manufacturers can achieve tighter tolerances and repeatability that manual processes often cannot provide. This improvement in quality control leads to less rework and higher customer satisfaction, ultimately driving the success of businesses. As the manufacturing sector continues to evolve, understanding the critical importance of CNC turning machines will be key for companies aiming to harness innovation and maintain a competitive edge in the market.

Key Factors to Evaluate When Sourcing CNC Turning Machine Suppliers

When sourcing CNC turning machine suppliers, evaluating key factors is paramount to ensure you partner with the right provider. The global CNC machine market is projected to grow significantly, from $101.22 billion in 2025 to an impressive $195.59 billion by 2032, with a compound annual growth rate (CAGR) of 9.9%. This surge highlights the increasing demand for high-quality CNC solutions, making it essential for manufacturers to select suppliers who can deliver reliable performance.

In this competitive landscape, manufacturers must consider several factors when assessing potential suppliers. First, the quality of the machines is critical; suppliers should provide evidence of precision engineering and advanced technology. Additionally, the supplier’s ability to adapt to economic pressures, such as rising costs and supply chain disruptions, is another vital consideration. With the CNC machines market reaching a valuation of $55.1 billion in 2022, aligning with a supplier who not only offers innovative solutions but also demonstrates strong adaptability can significantly impact operational efficiency and sustainability in production processes.

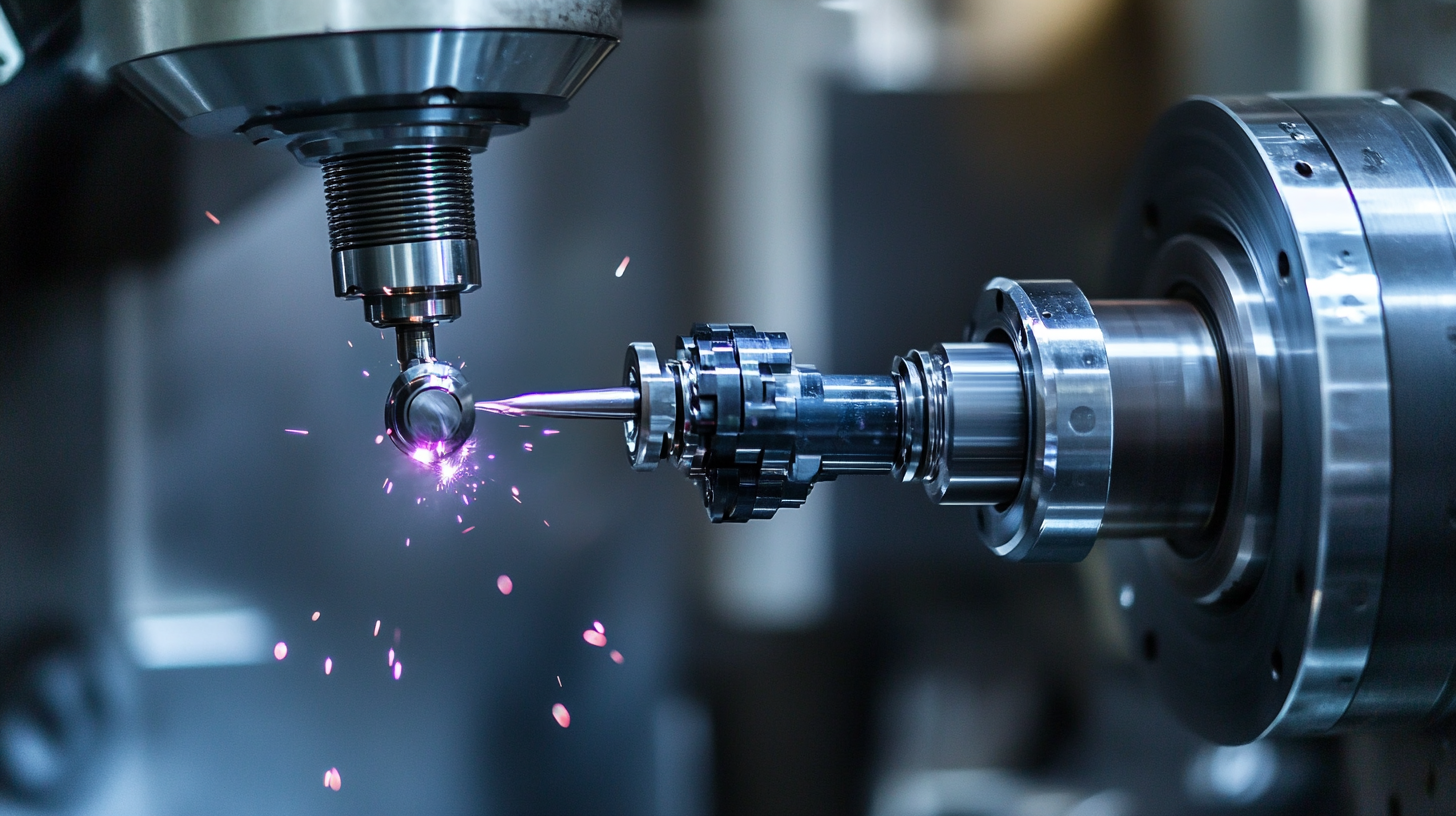

Analyzing Industry Trends: The Rise of Quality Assurance in CNC Manufacturing

In today's CNC manufacturing landscape, quality assurance has significantly risen to prominence. With the CNC controller market projected to grow from $3.2 billion in 2023 to an estimated $7.2 billion by 2033, achieving high standards in manufacturing processes becomes increasingly critical. This growth is driven by innovations in technology that enhance precision and efficiency, making quality control a focal point in the production process. The integration of structured light scanning and machine vision solutions is redefining quality control in factories, enabling manufacturers to ensure that every component meets stringent requirements.

Moreover, the CNC machining and turning centers market is also experiencing substantial growth, driven by industries such as automotive. Reports indicate that this market will continue to evolve, reflecting broader trends in automation and the need for enhanced quality assurance. As manufacturers seek to adopt advanced techniques, like AI and machine learning, they also boost their competitiveness by prioritizing quality. The trend towards adopting reliable cutting fluids and precision tools further amplifies these efforts, allowing companies to extend tool life and improve machining efficiencies, making it paramount for suppliers to recognize and adapt to these evolving demands.

Finding Quality Suppliers for Best Cnc Turning Machine with Proven Strategies and Insights - Analyzing Industry Trends: The Rise of Quality Assurance in CNC Manufacturing

| Dimension | Description | Current Trend | Quality Assurance Practices |

|---|---|---|---|

| Supplier Location | Geographic regions where suppliers are concentrated | Increasing preference for local sourcing | Regular audits and inspections |

| Materials Used | Types of materials utilized in CNC turning | Higher demand for sustainable materials | Certification of material sources |

| Technology Adoption | Level of advanced technologies integrated into processes | Shift towards automation and IoT | Implementation of digital quality management systems |

| Customer Feedback | Insights and evaluations from customers about suppliers | Growing use of online review platforms | Structured feedback collection processes |

| Pricing Strategies | Pricing models used by suppliers | Focus on value-based pricing | Transparent pricing practices |

Proven Strategies to Identify Reliable CNC Turning Machine Suppliers

When searching for reliable CNC turning machine suppliers, it’s essential to have a systematic approach to identify quality manufacturers. Start by conducting comprehensive research on potential suppliers. Utilize online platforms, industry forums, and trade shows to gather information on various manufacturers. Pay attention to their reputation, customer reviews, and the breadth of their product offerings. This foundational step will help you build a list of candidates worthy of further evaluation.

Once you have identified prospective suppliers, deep dive into their credentials. Check for certifications such as ISO 9001, which indicates a commitment to quality management. It's also crucial to assess their experience in the industry—companies with a long track record of service are often better equipped to handle complex projects. Additionally, initiating direct communication can provide insights into their customer service and responsiveness. Ask for samples or visit their facilities if possible, to better understand their manufacturing capabilities and quality control processes.

By combining thorough research with a careful vetting process, you can ensure you partner with a reliable CNC turning machine supplier that meets your operational needs.

Leveraging Data: Insights into the Performance of Chinese CNC Machinery Suppliers

In the competitive landscape of CNC machinery, leveraging data becomes crucial for identifying quality suppliers. By analyzing performance metrics, customer feedback, and market trends, businesses can gain invaluable insights into the strengths and weaknesses of various Chinese CNC machinery suppliers. This data-driven approach not only aids in evaluating the reliability of these suppliers but also helps businesses align their requirements with the right partners.

Furthermore, tracking supplier performance through data analytics allows companies to make informed decisions regarding procurement strategies. By monitoring aspects such as delivery times, product quality, and customer service, companies can create a comprehensive profile of each supplier. This can lead to better negotiation power and the ability to forge long-term partnerships with suppliers that consistently meet and exceed expectations. Investing in data analysis not only highlights effective suppliers but also streamlines the selection process, making it easier for businesses to find the best CNC turning machines tailored to their needs.