The Future of Precision Manufacturing: Revolutionizing Production with the Best Desktop CNC Milling Machine

The landscape of manufacturing is experiencing a transformative shift, driven by advancements in technology and an increasing demand for precision and efficiency. A significant player in this evolution is the Desktop CNC Milling Machine, which has emerged as a game-changer for both small-scale manufacturers and hobbyists alike. According to a recent industry report, the global CNC machine market is projected to reach $100 billion by 2025, with the desktop variant gaining popularity due to its affordability and compact design. These machines are not only enhancing production capabilities but also enabling a new wave of innovation in prototyping and custom manufacturing. As we delve deeper into the features and specifications of the best desktop CNC milling machines, we will explore how they are revolutionizing production processes across various industries, making precise machining accessible to a broader audience.

The Evolution of Desktop CNC Milling Machines in Precision Manufacturing

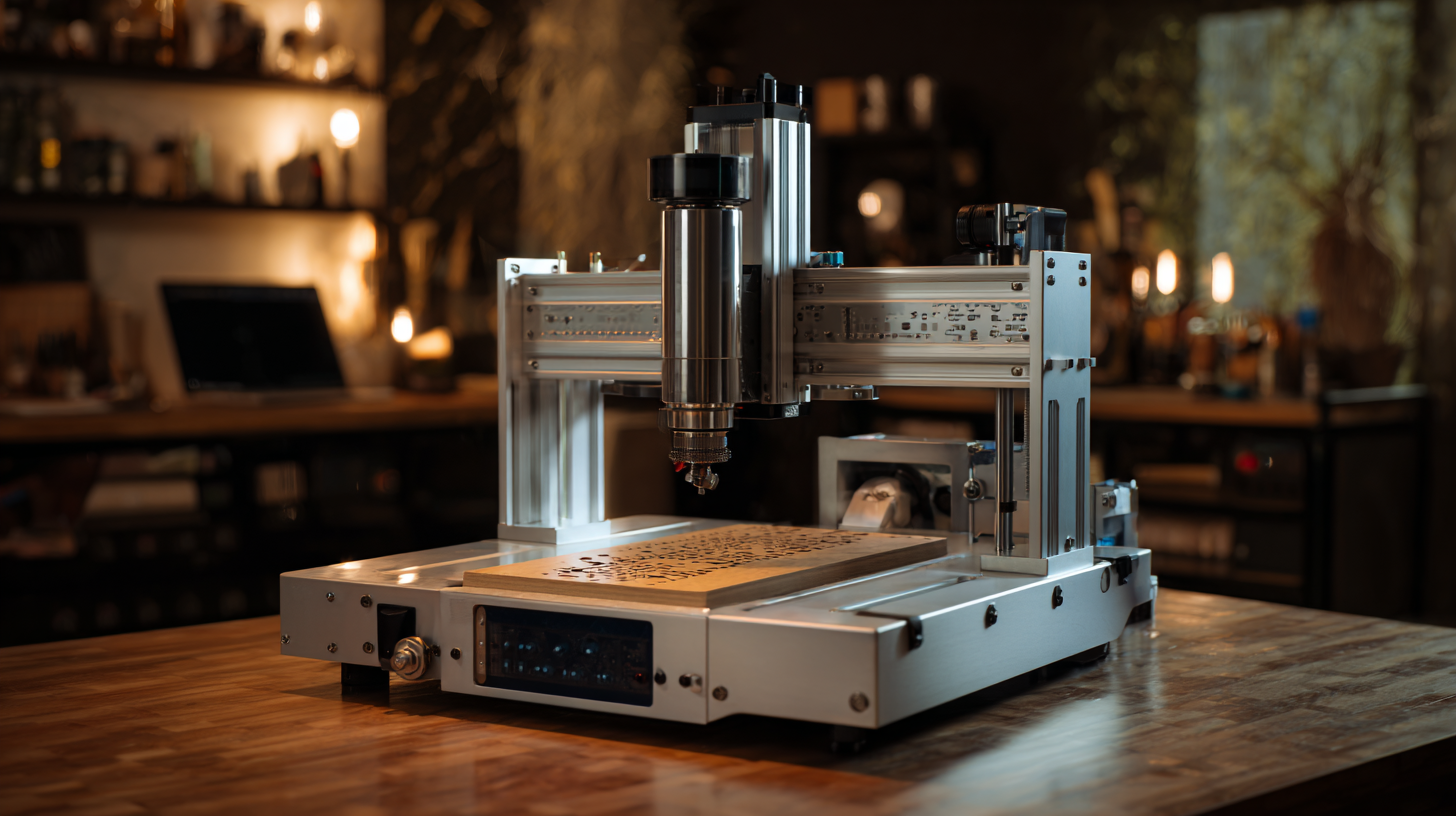

The evolution of desktop CNC milling machines has dramatically transformed the landscape of precision manufacturing. Initially, these machines were bulky and costly, limiting their accessibility to large industrial sectors. However, advancements in technology have led to compact, user-friendly models that can fit into small workshops and even home garages. This democratization of precision engineering allows hobbyists and small businesses to fabricate intricate designs that were once the exclusive domain of big manufacturers.

As desktop CNC milling machines have become more sophisticated, their capabilities have expanded, allowing for finer tolerances and diverse materials usage. Today's machines integrate advanced software that simplifies programming, enabling users with little to no machining experience to produce professional-grade results. Innovations such as automatic tool changers and improved spindle speeds further enhance productivity and precision. This evolution signals a future where personalized manufacturing is not just possible but prevalent, fostering creativity and innovation across various industries.

Key Benefits of Utilizing Desktop CNC Machines in Modern Production

The integration of desktop CNC milling machines in modern production has transformed how manufacturers approach precision engineering. According to a report by Deloitte, the global CNC machining market is expected to reach $117 billion by 2026, growing at a CAGR of 5.6%. This growth is driven largely by the increasing demand for high-precision components in industries such as aerospace, automotive, and healthcare, where the quality and accuracy of the final product are paramount.

Desktop CNC machines offer an accessible solution for smaller manufacturers, enabling them to produce intricate designs and maintain a competitive edge in high-stakes markets.

Desktop CNC machines offer an accessible solution for smaller manufacturers, enabling them to produce intricate designs and maintain a competitive edge in high-stakes markets.

One of the key benefits of utilizing desktop CNC machines lies in their efficiency and cost-effectiveness. These machines significantly reduce setup times and material waste, a vital factor highlighted in a study by the Manufacturing Institute, which estimates that process improvements in CNC operations can boost productivity by up to 30%. Additionally, desktop CNC systems provide unparalleled flexibility, allowing manufacturers to quickly adapt designs and produce small batches without the need for extensive retooling. This adaptability is crucial in today’s fast-paced market, where customization and rapid prototyping are paramount for meeting evolving consumer demands.

Comparative Analysis: Traditional vs. Desktop CNC Milling Technologies

In the realm of modern manufacturing, a significant debate revolves around the efficiency and applicability of traditional CNC milling technologies versus innovative desktop CNC machines. Traditional CNC milling machines are known for their robust capabilities and suitability for high-volume production runs, offering larger workspaces and the ability to handle extensive materials. However, they require substantial financial investment and a dedicated floor space, which can be a barrier for small businesses and hobbyists.

In contrast, desktop CNC milling machines have emerged as game-changers in the industry. These compact, user-friendly machines make precision manufacturing accessible to a broader audience, from startups to educational institutions. They maintain impressive accuracy and functionality while operating on a much smaller scale. Additionally, advancements in technology have made desktop CNC machines increasingly powerful, enabling them to mill a variety of materials with remarkable precision, all within a fraction of the operational costs associated with traditional models. This comparative analysis clearly illustrates how the shift towards desktop CNC milling is revolutionizing production processes and democratizing manufacturing capabilities for a diverse range of users.

The Future of Precision Manufacturing: Revolutionizing Production with the Best Desktop CNC Milling Machine

| Feature | Traditional CNC Milling | Desktop CNC Milling |

|---|---|---|

| Cost | $50,000 - $200,000 | $1,000 - $10,000 |

| Size | Large (industrial use) | Compact (desktop use) |

| Setup Time | Days to Weeks | Hours |

| Ease of Use | Requires skilled operators | User-friendly interface |

| Material Compatibility | Metals, Plastics, Composites | Plastics, Wood, Soft Metals |

| Production Speed | High production rates | Lower production rates |

| Precision | High precision | Good precision |

Market Trends: Demand and Growth Projections for Desktop CNC Solutions

The market for desktop CNC solutions is experiencing unprecedented growth, driven by advancements in technology and an increasing demand for precision manufacturing. According to a recent report by Markets and Markets, the global CNC machine market is expected to reach $100 billion by 2025, growing at a compound annual growth rate (CAGR) of 6.0% from 2020. This surge is largely fueled by the accessibility of desktop CNC milling machines, which allow small businesses and hobbyists to engage in high-quality production without the need for large-scale industrial equipment.

Additionally, the rise of the maker movement has significantly contributed to this trend. A study by Technavio projects that the demand for desktop CNC machines will grow by over 12% annually in the coming years. This increase is attributed to the growing DIY culture and the need for custom, low-volume production runs in various sectors such as aerospace, automotive, and healthcare. The affordability and user-friendly nature of these machines empower more individuals and small enterprises to innovate and optimize their manufacturing processes, reshaping the landscape of production.

Case Studies: Successful Implementations of Desktop CNC in Various Industries

Precision manufacturing is rapidly evolving, and desktop CNC milling machines are at the forefront of this revolution. Various industries have successfully integrated these advanced tools into their production processes, demonstrating their versatility and efficiency. For instance, in the aerospace sector, companies have utilized desktop CNC machines to create intricate components with minimal waste. By enabling rapid prototyping, these machines allow engineers to test designs quickly, leading to streamlined development cycles and reduced costs.

Another notable implementation can be found in the custom jewelry industry. Artisans have adopted desktop CNC milling machines to produce highly detailed and personalized pieces that were previously difficult to achieve. This technology not only enhances the quality of the work but also allows for greater creativity, enabling jewelers to push the boundaries of design. Similarly, in the education sector, schools and universities are incorporating desktop CNC milling into their curricula, equipping students with hands-on experience in advanced manufacturing techniques, thereby preparing the next generation of innovators for future challenges. These case studies highlight how desktop CNC technology is transforming production across diverse fields, enhancing both capability and efficiency.