Exploring Top Strategies to Source Reliable Home Cnc Machine Suppliers Globally

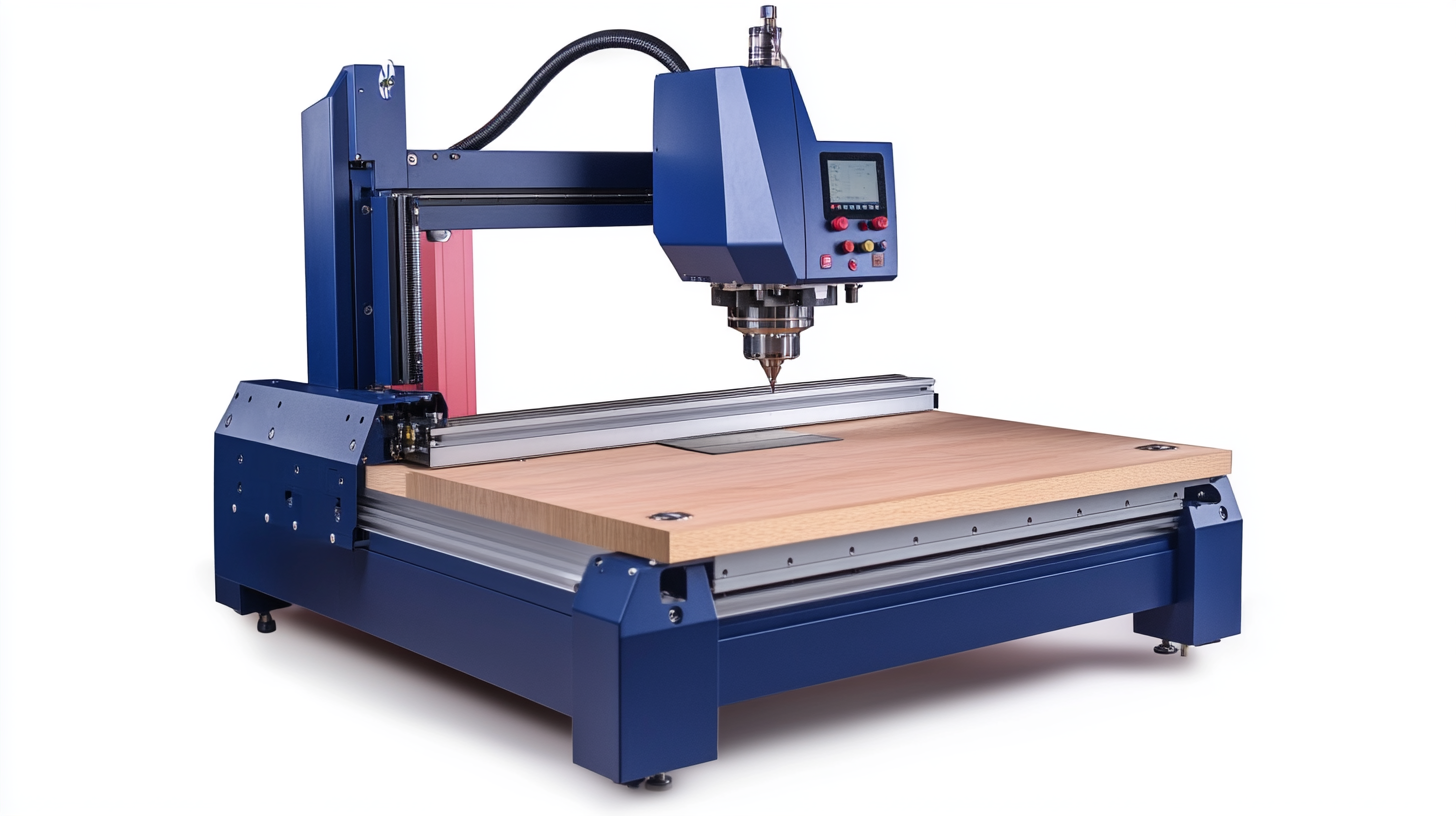

In today's world, changing at a breakneck speed in the field of manufacturing technology, house CNC machines have equally become the most demanded gadget by hobbyists, small business owners, and entrepreneurs as well. This tool allows them to make very complex designs, prototypes, and custom products from one location called 'home.' This market has become so much flooded with suppliers that it's quite a task locating good home CNC machine suppliers. This blog will take you through the hassles associated with sourcing reliable suppliers across the globe, providing useful insights and strategies for both novice and experienced buyers.

While probing the different landscapes of home CNC machine suppliers, one must note the actual criteria for determining reliability and quality. This includes everything from digging into the supplier credentials to noting market trends and customer reviews. The approach should be strategic as the quest of finding someone to supply for the perfect machine for someone starting a hobby or even someone looking to broaden his small business capabilities because trustworthy suppliers are essential. Here, join us as we take a dive into the best strategies for finding and dealing with the top home CNC suppliers across the world so that you can make informed choices that move your creative projects ahead.

Understanding the Importance of Reliable CNC Machine Suppliers in Home Projects

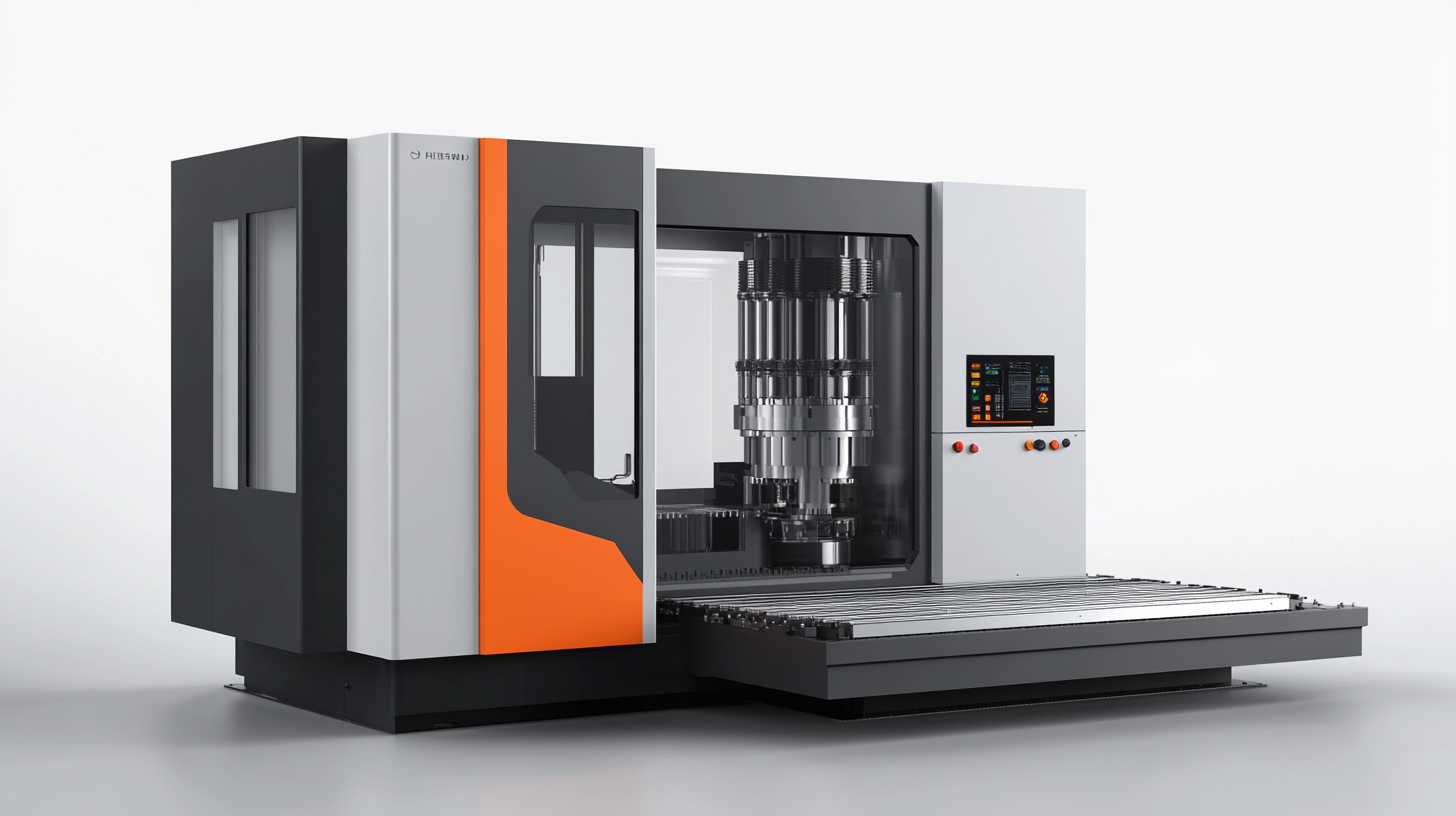

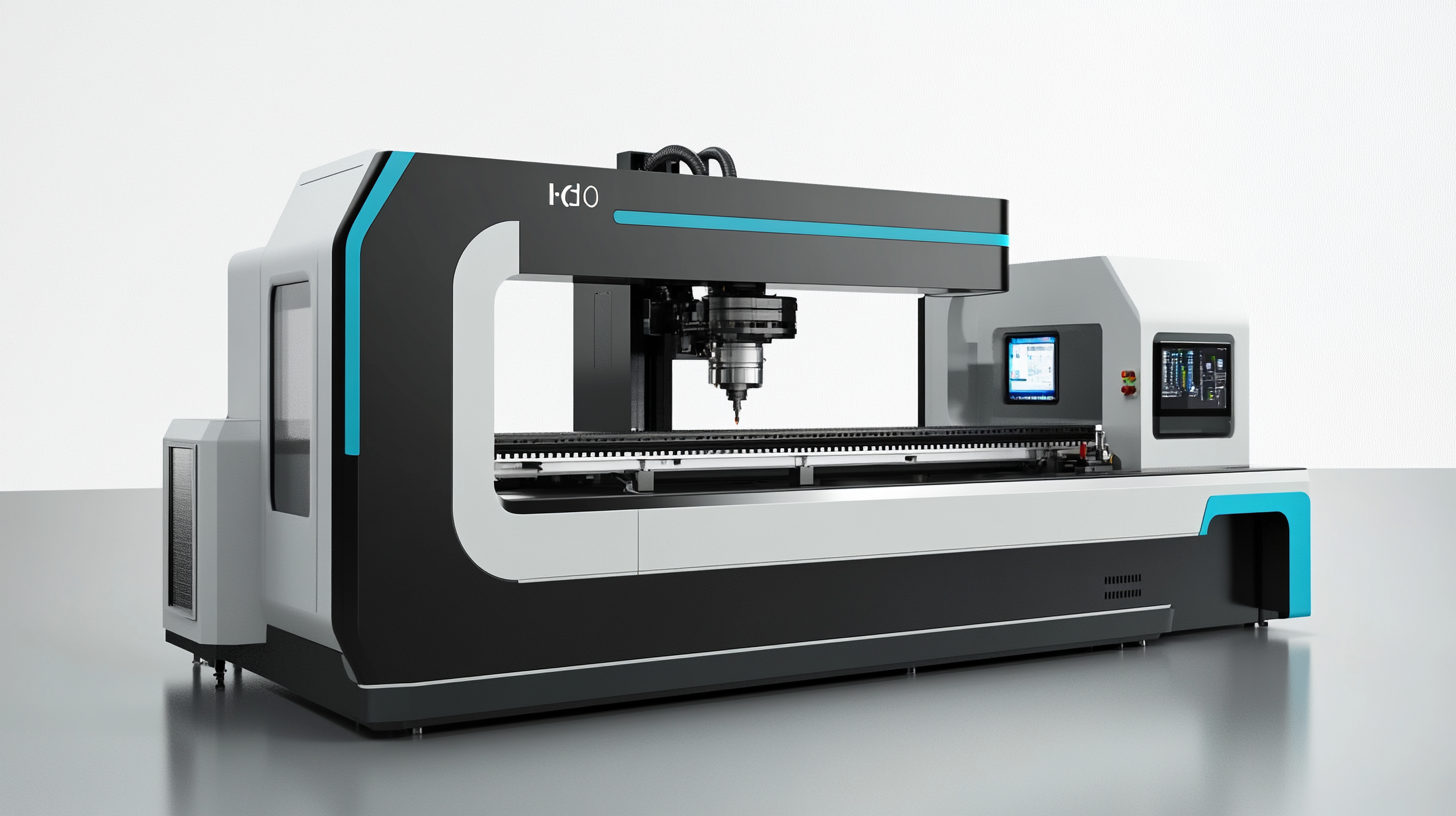

Now, it is important to realize reliability in CNC suppliers for home usage for projects to be successful. The pressing need for customized and higher-precision machining makes supplier reliability a must for hobbyists and small-scale businesses alike. Home CNC users depend on these suppliers for not just the machines but also timely and dependable support, quality parts, and delivery. The knowledge of trustworthy suppliers allows users to smoothly and efficiently finish their projects, hence being able to achieve their results in time without confusion. This sizable market is expected to grow chinks in the whole CNC machine market with newer technological demands for high guards upon newer efficient machines. From the analysts' standpoint, the CNC market has been forecasted to be nearing 450 billion yuan by the year 2025. The rise is not surprising, considering that-applications pertaining to exports and not so much home-use projects are benefiting. The growing precision for home applications is supplemented by fast and versatile techniques in metal cutting and forming. Investment in high-end CNC technologies also indicates their predominant role in industry and domestic applications. Innovative new developments are expected to further enhance home users' possibilities with newly acquired CNCs. Building the relationship with approved suppliers considerate of the need for individual clients is key to ensure project success. As the market continues to change, more information about the tools and techniques for home manufacturing has become absolutely crucial."

Key Criteria for Evaluating Home CNC Machine Suppliers Effectively

When hunting down a reliable home CNC machine supplier, you have to set key criterion so that you can weigh up potential partners. Start with product evaluation since this is really what determines the supplier's repute. The best suppliers should show a detailed specification of each machine, and this should include materials used, as well as its certification for verification to ensure conformity to industry standards. Customer testimonials and case studies also go a long way in terms of informing you about how operationally reliable and well-performing their products are.

Another consideration would be customer support and service. Buy a good qualified CNC machine and well be taking time and cost terms later on for maintenance/repairs needed. Think about technical support basics, ease in reaching, avenues for troubleshooting, and warranties.

Price is, of course, an important criterion, but it should never be the only determinant. Instead, consider the complete value by weighing a machine's quality against the value of customer service and other enhancements the supplier may include. It might be better value to purchase a somewhat more expensive machine where you get a complete support service than it would be to go for the cheaper alternative with no service. Focus on these criteria for sounder decision-making in sourcing home CNC machine suppliers globally.

Leveraging Online Platforms and Marketplaces to Find Trusted Suppliers

Getting online and utilizing the marketplaces to source credible home CNC machine suppliers worldwide are the steps that must be taken. As the global e-commerce market lures all sorts of businesses, online sourcing remains a vital part of any such endeavor. Alibaba, ThomasNet, and Maker's Row sites are a good starting place. Here one can find not just a host of suppliers, but also the systems that provide supplier ratings and scrutinize reviews, thus reflecting the credibility of that supplier.

Important points in an online sourcing of suppliers include gauging credibility and product quality. Detailed descriptions of the product offered for sale, such as user feedback or verified certificates, are essential to ascertain one entity's credibility over another. Good old engagement with communication features built into the supplier finding platforms also affords good documentation. Days of delays ahead are also created for any clarifying issues pertaining to their production or dispatch pattern.

Additionally, engaging in online forums and social media groups specific to the industry will assist in finding suppliers. Fellow entrepreneurs sometimes give references based on firsthand experiences, leading to credible sources that cannot be found with a basic internet search. Accordingly, the above-mentioned strategies will help nip to a large extent finding entry for businesses into the global market while also securing reliable suppliers for their home CNC machine requirement.

Building Relationships with CNC Suppliers for Long-Term Success

Build your strong relationships with CNC machine suppliers so that you can survive any manufacturing business for an extended period. In a scenario where companies have to turn to the rest of the world for most of their production requirements, the ability to develop trust and a sense of affiliation with your supplier becomes even more critical. These cities are major manufacturing hubs wherein supply chains for major tech companies, such as Apple, have a big footprint. Zhengzhou, Suzhou, and Shenzhen - among others.

Communication methods that guarantee openness and cooperation must therefore also be established. Such access includes constant visits to facilities, attendance in local exhibitions, and participation in community functions. It will create these interpersonal networks for the mutual understanding of capabilities and expectations. Within the high-speed CNC machining environment, where precision and reliability hold the key, a supplier who is willing to respond and adapt will dramatically affect production.

Moreover, using technology to make collaboration easier is becoming increasingly important; for example, quote management systems or collaborative platforms can help maintain the flow of communication so that the two parties will come to agree on as many of the operating principles as possible. This is necessary to keep misunderstanding to a minimum and also puts both parties in a stronger position for negotiations at some point in the future, establishing terms that are beneficial toward building a partnership. Basically, building these relationships solidifies the ground on which market shocks and innovation challenges can be banked on.

Navigating Global Trade Regulations When Sourcing CNC Machines Abroad

International sourcing of CNC machinery might involve comprehension of global trade regulations by manufacturers. An International Trade Centre report indicates that around 80% of companies doing international trade face hiccups in terms of varied regulations and compliance requirements. Export controls on such technologies and machinery can actually affect the import procurement, especially from those countries like the United States and EU with strict rules.

Another hurdle is the documentation requirement for CNC machines to be imported. Goods pass customs during 4 to 10 days, as indicated by a survey done by the World Bank depending on the country, thus necessitating ample preparations. Importers should also be very cognizant of the Harmonized System (HS) codes categorizing machinery for tariff purposes as misclassification would lead to delay and extra costs. Furthermore, i.e. with regard to recent trade agreements such as the USMCA, where there are potentially preferential tariffs but fine details need to be documented for compliance, a consideration.

Beside these, with the increase of digital trade, there are also many new cybersecurity regulations that suppliers will have to negotiate. According to the recent report of McKinsey, the very large portion of companies mentions that their decisions related to the supply chain are largely influenced by increasing concerns regarding data privacy laws. By understanding these regulations, risks associated with data breaches and compliance violations in sourcing CNC machines globally can be mitigated. That is why legal experts consult specialized platforms, and manufacturers should also do so to keep abreast of these new regulatory landscapes.