Exploring Industry Trends: Desktop CNC Milling Machines at the 138th Canton Fair 2025 - A Data-Driven Insight

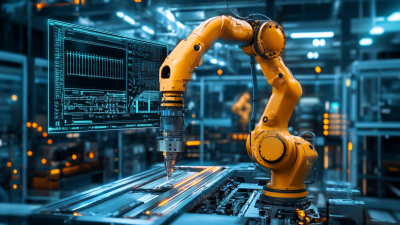

The rapidly evolving landscape of manufacturing technology underscores the significance of innovative tools such as the Desktop CNC Milling Machine. As we approach the 138th Canton Fair in 2025, industry professionals and enthusiasts alike are keenly exploring the latest trends and advancements in this domain. This seminal event will showcase an array of cutting-edge products, highlighting the pivotal role that Desktop CNC Milling Machines play in enhancing precision and efficiency across various sectors.

Leveraging data-driven insights, this analysis will delve into the emerging patterns observed at the Fair, focusing on how these machines are revolutionizing production processes for both small-scale workshops and large industrial operations. By examining current market trends and their implications for the future, we aim to provide a comprehensive understanding of the significance of these tools in shaping the manufacturing landscape in the coming years.

Emerging Technologies in Desktop CNC Milling Machines at the 138th Canton Fair

At the 138th Canton Fair in 2025, the spotlight will shine on emerging technologies in desktop CNC milling machines, marking a pivotal moment for innovation in the field. This year's exhibition will showcase advancements such as enhanced precision through AI-driven software, which optimizes machining processes and reduces human error. Additionally, the integration of IoT connectivity will allow operators to monitor and control machines remotely, further streamlining production workflows and improving efficiency.

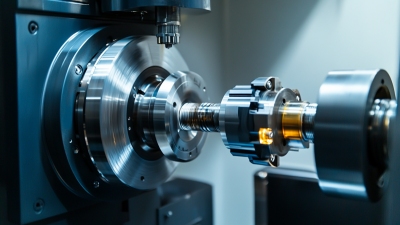

Moreover, the introduction of eco-friendly materials and energy-efficient designs is set to revolutionize the desktop CNC milling segment. Manufacturers are now prioritizing sustainability, responding to growing consumer demand for greener technologies. Attendees can expect to engage with cutting-edge developments that not only boost productivity but also align with environmental standards, making these machines an attractive choice for modern fabrication shops. The innovations presented at the Canton Fair will undoubtedly shape the future landscape of desktop CNC milling, pushing the boundaries of what is possible in precision engineering.

Emerging Technologies in Desktop CNC Milling Machines at the 138th Canton Fair 2025

Market Growth Projections: The Rise of CNC Milling Machinery in 2025

The global dental milling machine market is anticipated to grow from USD 984.9 million in 2025 to USD 1,865 million by 2032, reflecting a compound annual growth rate (CAGR) of 9.5%. This robust growth in the CNC milling machinery sector is underpinned by increasing automation and technological advancements, which are driving demand across various applications. Furthermore, the CNC machine tool market in China is projected to surpass CNY 450 billion in 2025, highlighting the critical role that such technology plays in enhancing manufacturing efficiency and precision.

In addition to dental milling machines, the broader landscape of CNC machinery demonstrates significant growth potential. Reports indicate that the CNC machine tool market, valued at CNY 4.09 trillion in 2023, is expected to achieve a CAGR of 5.75% through 2024. The push for innovation in sectors like automotive, industrial equipment, and precision engineering is fueling investments in high-end machines, particularly five-axis CNC systems, which stand at the forefront of this evolution. These trends reflect a shifting paradigm towards increased adoption of automated solutions to meet growing industrial demands.

Comparative Analysis of CNC Milling Machine Capabilities and Applications

At the upcoming Canton Fair 2025, the spotlight will be on desktop CNC milling machines, showcasing a surge in technological advancements and applications. This comparative analysis will delve into the various capabilities of different CNC milling machines, emphasizing their unique features, such as precision, versatility, and ease of use. As industries continue to adopt automated solutions, understanding these differences is crucial for manufacturers seeking to enhance productivity and innovation.

Tips: When evaluating CNC machines, consider the material compatibility and production volume you require. High precision models are essential for intricate designs, while larger machines could better serve mass production needs. Be sure to analyze customer reviews and machine specifications to identify the best fit for your specific projects.

In addition to technical specifications, applications of these machines can vary significantly across fields such as aerospace, automotive, and educational purposes. This fair provides an ideal opportunity for attendees to gain insights into how different CNC milling machines perform under varying conditions and requirements. By staying informed about the latest trends and technologies, manufacturers can make more informed decisions that align with their strategic objectives.

Tips: Network with industry professionals at the fair to gain firsthand insights and potential partnerships that could lead to innovative solutions for your business. Engaging with experts can also give you a clearer picture of emerging trends and technologies within the CNC milling sector.

Sustainability Trends: Eco-Friendly Innovations in Desktop CNC Milling

The desktop CNC milling machine sector is significantly influenced by sustainability trends as manufacturers increasingly adopt eco-friendly innovations. As the global CNC milling market is projected to grow from USD 83.09 billion in 2024 to USD 103.92 billion by 2032, there's a notable shift towards integrating advanced design automation that emphasizes sustainability. This surge is driven by the growing demand for machines that not only deliver high performance but also minimize environmental impact.

Moreover, the rise of generative CNC technology, expected to reach USD 6,294 million by 2035, underscores the trend towards efficiency and reduced waste in the production process. Generative design algorithms optimize material usage, aligning perfectly with circular economy principles aimed at sustainability. This innovation enables manufacturers to create products that are not only aesthetically pleasing but also environmentally responsible, showcasing the balance between industrial advancement and ecological sensitivity. As such, the 138th Canton Fair in 2025 will likely highlight these advancements, reflecting a commitment to an eco-friendly future in the CNC industry.

Consumer Demand and Industry Adaptation: Insights from the Canton Fair 2025 Data

At the 138th Canton Fair 2025, a visible shift in consumer demand is reshaping the landscape for desktop CNC milling machines. Data collected during the event reveals an increasing preference for compact, versatile, and user-friendly models that cater not only to industrial users but also to hobbyists and small businesses. The innovation of features such as enhanced automation, improved software interfaces, and energy efficiency has become a focal point, indicating that consumers are seeking solutions that blend performance with sustainability.

Industry players are responding to this demand by adapting their offerings and marketing strategies. Companies are leveraging data analytics to predict trends and align their product development with consumer expectations. The fair showcased a range of exhibitors emphasizing customization options and ease of use, aiming to meet the diverse needs of the market. This data-driven approach highlights the importance of understanding consumer behavior and preferences, which is essential for staying competitive in the rapidly evolving CNC milling machine sector.

Exploring Industry Trends: Desktop CNC Milling Machines at the 138th Canton Fair 2025

| Dimension | 2023 Demand (%) | 2024 Projected Demand (%) | Industry Adaptation Strategies |

|---|---|---|---|

| Consumer Awareness | 35% | 42% | Educational Campaigns |

| Technology Incorporation | 45% | 50% | R&D Investments |

| Sustainability Practices | 28% | 36% | Eco-friendly Materials |

| Customization Options | 50% | 58% | Flexible Manufacturing |

| Pricing Competitiveness | 30% | 40% | Cost Reduction Techniques |

Related Posts

-

Challenges Faced by Global Buyers When Selecting the Best Desktop CNC Milling Machines

-

The Future of Precision Manufacturing: Revolutionizing Production with the Best Desktop CNC Milling Machine

-

Transforming Manufacturing: 2025 Innovations in CNC Turning Machines & Buyer’s Guide

-

Unlocking Precision: The Advantages of Investing in a Mini CNC Mill for Your Workshop

-

Choosing the Right Manufacturer for Your Best Axis CNC Needs

-

Finding Quality Suppliers for Best Cnc Turning Machine with Proven Strategies and Insights