Innovative Approaches to Sourcing the Best Desktop Cnc Milling Machine Worldwide

In today’s rapidly evolving manufacturing landscape, the demand for precision and versatility is at an all-time high, particularly in the realm of Desktop CNC Milling Machines. According to a recent industry report by MarketsandMarkets, the global CNC machine market is projected to reach USD 100 billion by 2025, underscoring the increasing reliance on these machines for both hobbyist and professional applications. As businesses and makers strive to stay competitive, sourcing high-quality suppliers for Desktop CNC Milling Machines has become paramount. This blog will explore innovative approaches to identifying and evaluating the best suppliers worldwide, ensuring that manufacturers unlock the full potential of their machining capabilities while maintaining cost-effectiveness and reliability in their production processes. Whether you are an established enterprise or a burgeoning startup, understanding how to navigate this complex market will be crucial for achieving operational excellence.

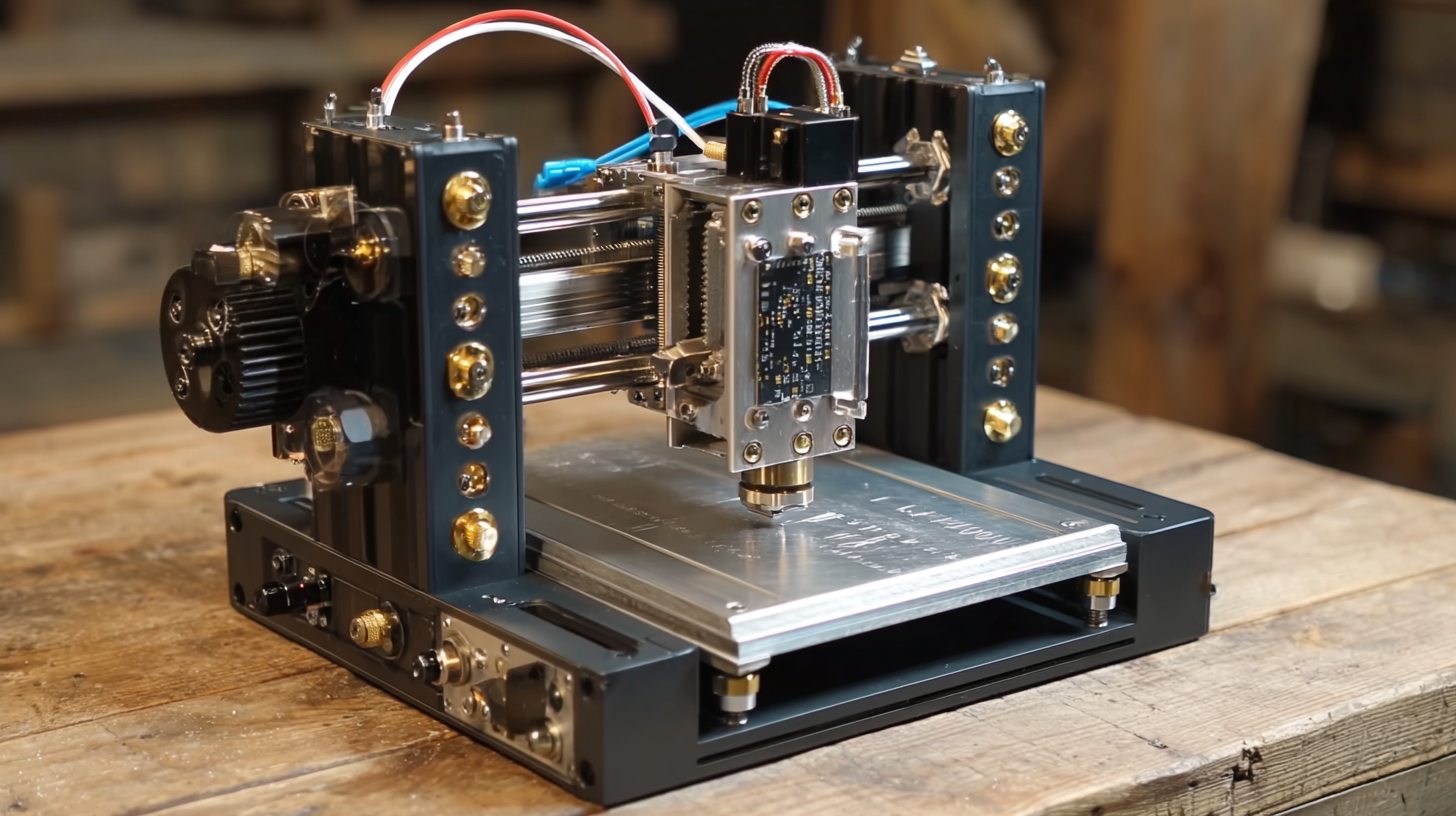

Key Technical Specifications to Consider When Choosing a Desktop CNC Milling Machine

When choosing a desktop CNC milling machine, understanding the key technical specifications is crucial for making an informed decision. Firstly, the spindle speed and power can significantly influence the machine’s capability. A higher spindle speed allows for faster machining and the ability to work with various materials, from soft plastics to hard metals. Power, measured in watts, affects the machine's efficiency and cutting performance; thus, it’s essential to select a unit that can handle the specific materials you intend to work with.

Another vital consideration is the machine’s working area, which directly impacts the size of the projects you can undertake. A larger work area offers versatility, enabling the machining of bigger parts without the need for multiple setups. Additionally, look for features such as a robust frame, which ensures stability during operation, and precision in the motion system—such as linear guides and lead screws—which contribute to accuracy and repeatability in your machining tasks. Evaluating these specifications will help you find a desktop CNC milling machine that meets your needs and supports your creative projects effectively.

Innovative Approaches to Sourcing the Best Desktop CNC Milling Machine Worldwide

This bar chart illustrates the importance ratings for key technical specifications to consider when choosing a desktop CNC milling machine. Ratings are based on factors such as precision, speed, stability, software compatibility, and user-friendly interface.

Understanding Different Types of Desktop CNC Milling Machines Available in the Market

The desktop CNC milling machine market has witnessed significant growth, driven by the increasing demand for precision engineering and prototyping across various industries. According to the Business Research Company, the global market size is expected to expand markedly in 2023, propelled by innovations in machine technology and the rising trend of DIY manufacturing. This surge is largely attributed to the versatility of desktop CNC machines in both metal cutting and forming applications, making them an essential tool for makers, engineers, and small businesses alike.

When it comes to selecting the right desktop CNC milling machine, understanding the different types available on the market is crucial. These machines can be categorized based on their primary functions: metal cutting machines are designed for precise shaping and finishing of metal parts, while metal forming machines excel in bending and molding materials. The latest advancements in digital twin technology also play a role in optimizing machine performance, allowing manufacturers to simulate machining processes digitally before actual production. With the right choice, users can enhance their capabilities and efficiency in producing high-quality outputs.

Comparative Analysis of Leading Brands in Desktop CNC Milling Technology

When it comes to selecting the best desktop CNC milling machine, a comparative analysis of leading brands is crucial for informed decision-making. Each manufacturer brings unique features to the table, often tailored to different user needs. For instance, brands like X-Carve and Shapeoko are well-regarded for their user-friendly setups and robust online communities, making them ideal for beginners. These machines often highlight accessibility without compromising on precision, making them popular choices for hobbyists and small workshops.

On the other hand, brands like Tormach and Othermill are geared towards professionals seeking higher performance and advanced capabilities. Tormach's machines, for instance, are known for their exceptional build quality and reliability, catering to those who require consistent output for small batch manufacturing. Meanwhile, Othermill stands out in the market with its compact design and innovative software integration, which appeals to tech-savvy users looking for versatility in their milling projects. By evaluating these comparative strengths, individuals can better navigate the diverse offerings available and pinpoint the machine that aligns with their specific milling needs and budget.

Innovative Approaches to Sourcing the Best Desktop CNC Milling Machine Worldwide - Comparative Analysis of Leading Brands in Desktop CNC Milling Technology

| Feature | Machine A | Machine B | Machine C | Machine D |

|---|---|---|---|---|

| Maximum Cutting Speed (mm/min) | 5000 | 6000 | 4500 | 5200 |

| Work Area (mm) | 300 x 200 x 150 | 400 x 300 x 200 | 250 x 200 x 150 | 350 x 250 x 200 |

| Spindle Power (W) | 500 | 750 | 450 | 600 |

| Weight (kg) | 30 | 40 | 25 | 35 |

| Price (USD) | 2000 | 2500 | 1800 | 2200 |

Step-by-Step Guide: How to Select the Right CNC Milling Machine for Your Needs

When selecting the right CNC milling machine, it's essential to start with a clear understanding of your specific needs. According to a Market Research Future report, the global CNC machine market is expected to reach approximately $100 billion by 2026, driven by increased automation in manufacturing. Thus, identifying whether you need a desktop model for prototyping or a more robust system for high-volume production is crucial. Factors such as the size of the materials you'll be working with, the types of materials, and the complexity of the designs will greatly influence your choice.

Once you've defined your requirements, consider the specifications of the machines available. The spindle speed, feed rate, and precision are key parameters. For instance, a study by SmarTech Publishing indicates that high-precision CNC machines, which offer tolerances within 0.002 inches, are in high demand for industries such as aerospace and healthcare. Lastly, assess the supplier's support, warranty options, and the availability of spare parts, as these aspects can significantly impact your operational efficiency in the long run. By following these steps, you can make a well-informed decision that aligns with your production goals.

Innovative Features to Look for in Cutting-Edge Desktop CNC Milling Machines

When exploring innovative features in cutting-edge desktop CNC milling machines, efficiency and versatility stand out as key attributes. Recent industry reports indicate a growing demand for machines that offer superior precision while accommodating various materials, from soft plastics to hard metals. Look for models equipped with advanced spindle designs, which can enhance cutting speed and maintain higher torque at lower RPMs, optimizing both quality and productivity.

Additionally, automation features such as built-in tool changers and user-friendly software interfaces are becoming increasingly prevalent. These advancements significantly reduce setup time, allowing hobbyists and professionals alike to focus more on creativity and less on mechanical adjustments. For those considering a purchase, pay attention to machine compatibility with CAD/CAM software, as seamless integration can expedite the design-to-production workflow.

Tip: Always check for the latest firmware updates from manufacturers, as these can unlock new functionalities and enhance machine performance.

Another essential feature to consider is the machine's ability to connect with IoT devices, which provides remote monitoring and real-time feedback. This capability not only improves maintenance schedules but also maximizes operational uptime—an invaluable factor in today's fast-paced manufacturing landscape.

Tip: Evaluating customer reviews and product demos can provide insight into a machine's performance and reliability before making a purchasing decision.