Unlocking Precision: The Advantages of Investing in a Mini CNC Mill for Your Workshop

In today's rapidly evolving manufacturing landscape, precision and efficiency are paramount for any workshop seeking to maintain a competitive edge. The global CNC machining market was valued at approximately $63 billion in 2021 and is projected to reach $100 billion by 2028, highlighting the growing demand for advanced machining technologies. Among these innovations, the Mini CNC Mill stands out as a versatile solution tailored for small to medium-scale operations. By providing unparalleled accuracy, reduced material waste, and increased production speeds, investing in a Mini CNC Mill enables workshops to streamline their processes while catering to the rising trend of custom and intricate designs. This blog will explore the advantages of incorporating a Mini CNC Mill into your workshop, presenting compelling reasons that emphasize its value in today’s precision-driven industry.

The Evolution of CNC Milling: Why Mini CNC Mills Are Gaining Popularity

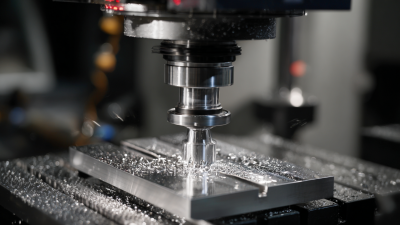

The evolution of CNC milling technology has positioned mini CNC mills as an increasingly popular choice among makers, hobbyists, and small businesses. The emerging trends in the desktop CNC machine market illustrate a significant shift towards more compact, high-precision solutions. According to market analysis, the global CNC machine tools market is projected to grow by USD 21.9 billion from 2025 to 2029, driven by a rising demand for high-precision, multi-axis machining centers. This trend underscores the growing recognition of mini CNC mills as efficient tools that can deliver professional-grade results without the space and cost requirements of larger machines.

Moreover, the accessibility and versatility of mini CNC mills are transforming how DIY enthusiasts approach their projects. With the capabilities to undertake various tasks—from intricate carvings to precise cutouts—these machines cater to both casual users and dedicated entrepreneurs. As the market for desktop CNC machines continues expanding, fueled by technological advancements and increased consumer interest, mini CNC mills are becoming indispensable assets in workshops worldwide. This accessibility is further enhanced by the integration of AI technologies, driving innovation and refining performance in CNC machining, ultimately unlocking new possibilities for creativity and production.

Unlocking Precision: The Advantages of Investing in a Mini CNC Mill for Your Workshop

| Feature | Mini CNC Mill | Traditional CNC Mill |

|---|---|---|

| Cost | $1,000 - $5,000 | $10,000 - $100,000 |

| Size | Compact | Large |

| Precision | Up to 0.01 mm | Up to 0.005 mm |

| Ease of Use | Beginner Friendly | Requires Expertise |

| Applications | Hobby Projects, Prototyping | Industrial Production |

| Portability | High | Low |

| Maintenance | Low | High |

Top Features to Look for When Choosing the Right Mini CNC Mill

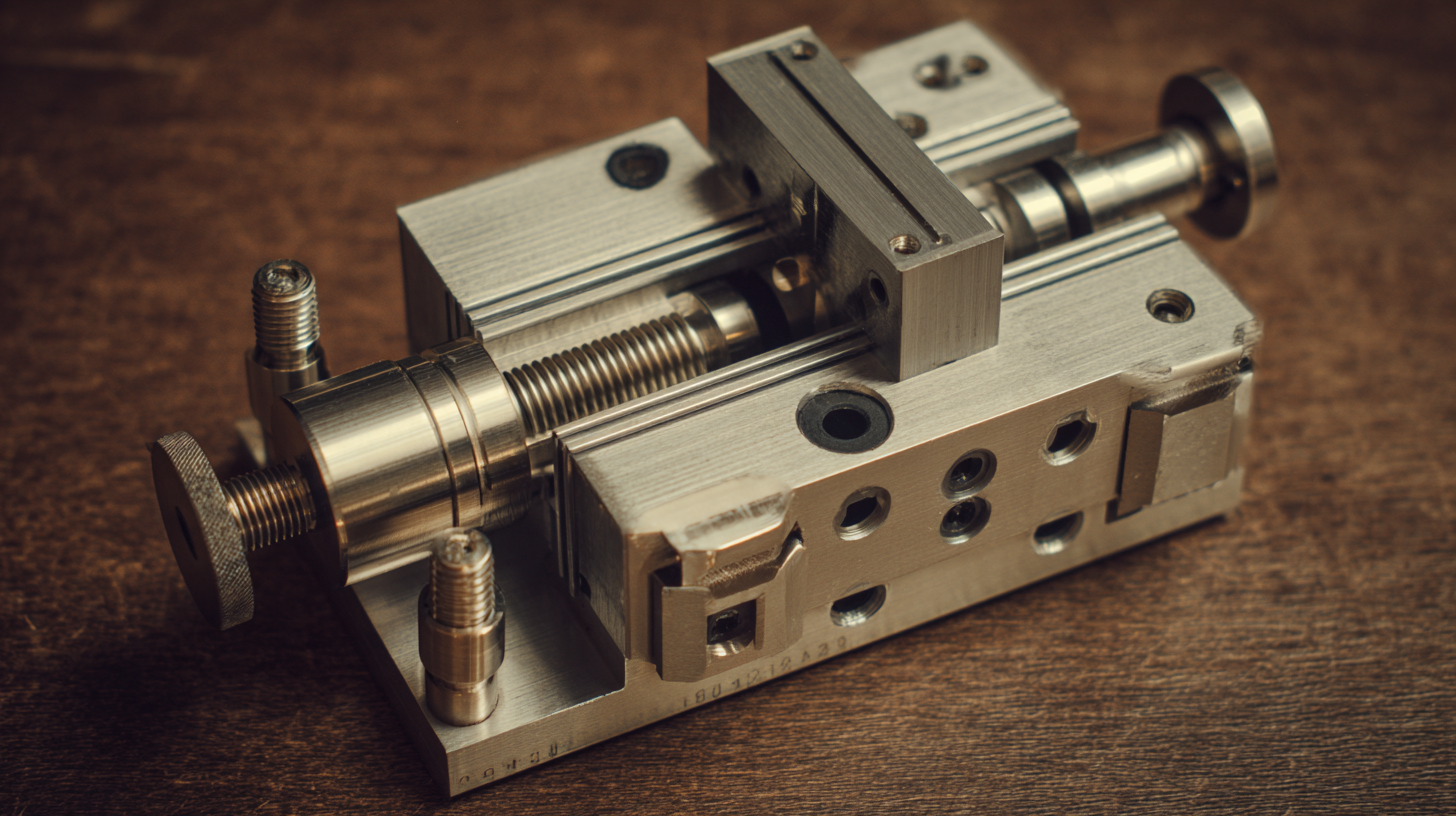

When selecting a mini CNC mill for your workshop, several key features can elevate your projects from mediocre to exceptional. One crucial aspect is precision; look for machines with a repeatability tolerance of at least 0.001 inches. This level of accuracy allows for intricate designs and finer details, making it ideal for both prototyping and production work.

Another important feature to consider is the machine's compatibility with various materials. Many mini CNC mills can handle a range of substrates, from wood to plastics and metals, expanding your creative potential. Recent reports indicate that versatile CNC machines are trending in the DIY community due to their multifunctional capabilities. For instance, some models now integrate 3D printing and laser engraving features, providing a comprehensive solution for makers looking to diversify their skill set.

Lastly, don't underestimate the importance of robust software support. The best mini CNC mills come bundled with user-friendly design programs or are compatible with free software alternatives. This can significantly streamline your workflow, allowing you to turn ideas into tangible products faster. As the market for desktop CNC machines grows, investing in one equipped with these features can position your workshop for success.

Cost-Effectiveness: Comparing Mini CNC Mills to Traditional Milling Machines

When considering the integration of CNC technology into a workshop, many enthusiasts and professionals face a critical decision: whether to invest in a mini CNC mill or a traditional milling machine. The cost-effectiveness of mini CNC mills is a significant advantage, particularly for hobbyists and small businesses. Mini CNC mills typically have a lower initial purchase price, making them accessible for those with budget constraints. This affordability does not compromise functionality, as these machines offer precise machining capabilities that rival their larger counterparts.

In addition to the initial investment, mini CNC mills often incur lower ongoing operational costs. They usually consume less power and require less maintenance compared to traditional machines, which can lead to substantial savings over time. Furthermore, their compact size means they require less floor space, allowing workshops to maximize their operational area. For individuals and small businesses aiming to enhance productivity without overspending, a mini CNC mill presents an ideal solution, offering reliability and efficiency while remaining financially viable.

Enhancing Precision in Your Projects with a Mini CNC Mill

When it comes to enhancing precision in your projects, a mini CNC mill emerges as an indispensable tool for workshop enthusiasts and professionals alike. This compact machine allows for exceptionally detailed work, making it easier to achieve intricate designs and exact specifications. Whether you're working on small-scale prototypes or custom parts, a mini CNC mill can elevate the quality of your projects significantly.

Tip: To maximize the precision of your mini CNC mill, ensure that your workspace is clean and free from debris. A clutter-free environment not only helps maintain the machine but also enables you to focus on your projects without distractions. Additionally, regularly calibrate your machine for the best results.

Investing in a mini CNC mill also opens up new avenues for creativity. With its capability for complex cuts and diverse materials, your design possibilities expand. This versatility allows for the creation of customized components that can perfectly fit your vision, setting your projects apart.

Tip: Experiment with different materials and cut settings to discover the optimal configuration for your design requirements. Keeping a record of successful settings will help streamline your future projects and boost productivity.

Space-Saving Solutions: How Mini CNC Mills Fit into Any Workshop

In today’s fast-paced crafting and manufacturing world, mini CNC mills are proving to be game-changers for workshop enthusiasts. One of the most compelling reasons to invest in a mini CNC mill is its ability to fit into any workshop, regardless of size. According to a 2022 industry report, approximately 70% of DIY enthusiasts operate in spaces smaller than 500 square feet, which emphasizes the need for space-efficient solutions. Mini CNC mills offer a compact alternative without sacrificing functionality, allowing users to execute precise milling tasks within a limited footprint.

Moreover, investing in a mini CNC mill enhances not only the diversity of projects that can be tackled but also the collaborative potential of shared maker spaces. These cooperative environments have seen a significant rise; a survey revealed that 45% of makers reported increased innovation and creativity through shared resources. By leveraging the capabilities of mini CNC mills, individuals can access advanced manufacturing technologies without requiring extensive space or investment, fostering a community-driven approach to making. As these tools become more prevalent, they empower workshop owners to maximize their potential, no matter the size of their workspace.

Related Posts

-

Understanding Manufacturing Standards for the Best Desktop CNC Milling Machine for Global Buyers

-

Transforming Manufacturing: 2025 Innovations in CNC Turning Machines & Buyer’s Guide

-

Exploring Cnc Machine Technologies Shaping the Future of Global Manufacturing by 2025

-

Maximizing Your Investment: How Post-Sales Support and Maintenance Costs Impact Desktop Milling Machine Efficiency

-

Future Trends in CNC Turning Machines and Global Market Comparisons for 2025

-

Exploring Innovative Alternatives to Small Milling Machines: A Data-Driven Approach for Enhanced Precision