Understanding Manufacturing Standards for the Best Desktop CNC Milling Machine for Global Buyers

In the rapidly evolving world of manufacturing, selecting the right Desktop CNC Milling Machine is crucial for both efficiency and precision. As global buyers navigate the sea of options available, understanding manufacturing standards becomes a vital part of the decision-making process.

This blog will guide you through the essential steps to identify high-quality suppliers and ensure that you are making an informed investment. From recognizing the significance of certifications to evaluating technical specifications, we will delve into the critical aspects that differentiate a top-tier milling machine from the rest.

Whether you’re a seasoned manufacturer or new to the CNC landscape, our comprehensive approach aims to empower you with the knowledge needed to choose a Desktop CNC Milling Machine that meets your specific requirements while adhering to international standards.

Importance of Manufacturing Standards in CNC Milling Machines

Manufacturing standards play a crucial role in the realm of CNC milling machines, particularly for global buyers seeking the best desktop models. These standards, which encompass safety, quality, and performance specifications, ensure that machines meet international requirements, making it easier for consumers to make informed purchasing decisions. For manufacturers, adhering to these standards not only enhances product reliability but also builds trust with customers who depend on consistent results.

Moreover, compliance with manufacturing standards helps streamline the integration of CNC milling machines into existing workflows. When machines are designed and constructed according to recognized benchmarks, they are more likely to operate efficiently alongside other tools and technologies. This interoperability is especially vital in a global market where various manufacturers and users may have differing levels of expertise and expectations. Ultimately, prioritizing manufacturing standards in CNC milling machines enables buyers to invest confidently in equipment that delivers precision and durability, vital qualities for any manufacturing process.

Understanding Manufacturing Standards for the Best Desktop CNC Milling Machine for Global Buyers - Importance of Manufacturing Standards in CNC Milling Machines

| Dimension | Standard | Importance |

|---|---|---|

| Accuracy | ISO 230-2 | Ensures precision in machining processes |

| Safety | ANSI/RIA R15.06 | Minimizes risks and promotes safe operation |

| Interoperability | ISO/IEC 15067-3 | Facilitates integration with other systems |

| Quality | ISO 9001 | Ensures consistent quality management practices |

| Environmental Impact | ISO 14001 | Promotes sustainable manufacturing processes |

| Performance | ISO 10791 | Measures machine tool performance specifications |

Key Features to Look for in a Desktop CNC Milling Machine

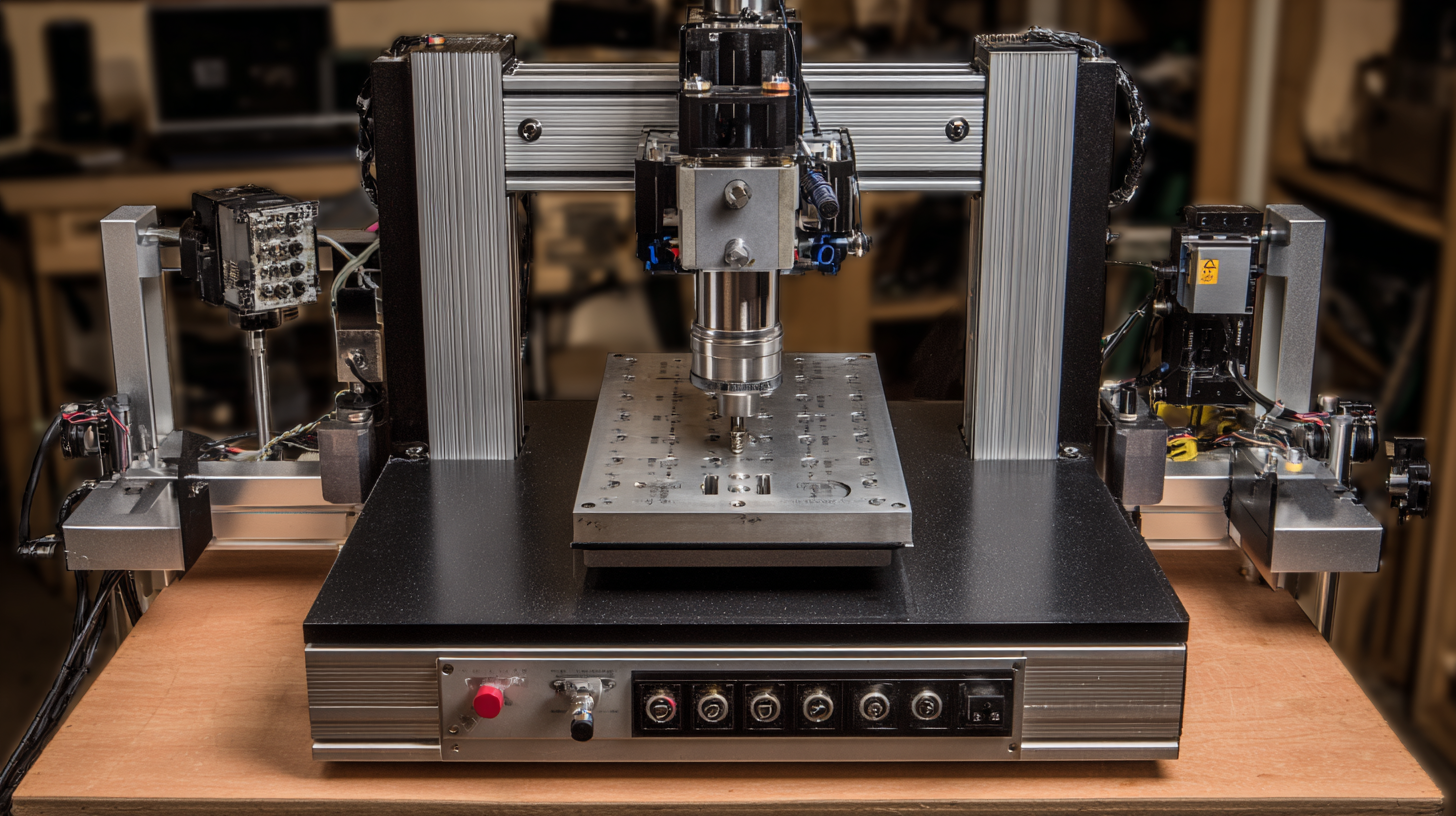

When selecting a desktop CNC milling machine, understanding the key features is essential for making an informed decision. One of the most critical aspects is the machine's build quality and rigidity. A robust structure not only ensures precision in cuts but also enhances the longevity of the machine. Buyers should look for mills made from high-quality materials, such as aluminum or cast iron, which can withstand the rigors of intensive machining. Additionally, vibration dampening features can significantly improve performance and accuracy during operation.

Another vital feature to consider is the software compatibility and user interface of the CNC milling machine. A user-friendly interface can make a significant difference, especially for beginners. Look for machines that come with comprehensive software support, enabling smooth transitions from design to production. Furthermore, compatibility with popular design software like SolidWorks or Fusion 360 can help in streamlining workflow processes. Lastly, evaluating the machine's precision specifications, such as repeatability and resolution, will directly affect the quality of the end products, making it imperative to choose a model that meets these high standards.

Comparing Global Manufacturing Standards for CNC Equipment

When choosing a desktop CNC milling machine, understanding global manufacturing standards is crucial for buyers seeking quality and reliability. Different countries maintain various regulations and guidelines that influence the performance and safety of CNC equipment. For instance, the ANSI (American National Standards Institute) sets extensive safety and operational standards for manufacturing in the U.S., while the European Union relies on CE marking to signify compliance with health, safety, and environmental protection standards. According to a report by MarketsandMarkets, the global market for CNC machines is expected to reach $100 billion by 2026, emphasizing the importance of adhering to these standards to meet increasing demand while ensuring user safety.

In the Asia-Pacific region, manufacturers often follow JIS (Japanese Industrial Standards), which ensure that products meet specific quality specifications. The coordination of these international standards is vital as it paves the way for manufacturers to export their products worldwide. A 2021 study by IBISWorld noted that companies adhering to these standards report lower product failure rates, enhanced customer satisfaction, and improved market competitiveness. Thus, understanding and comparing these global manufacturing standards are essential for buyers to ensure they invest in machines that are not only capable but also compliant with international expectations.

Evaluating Performance Metrics for Different CNC Milling Machines

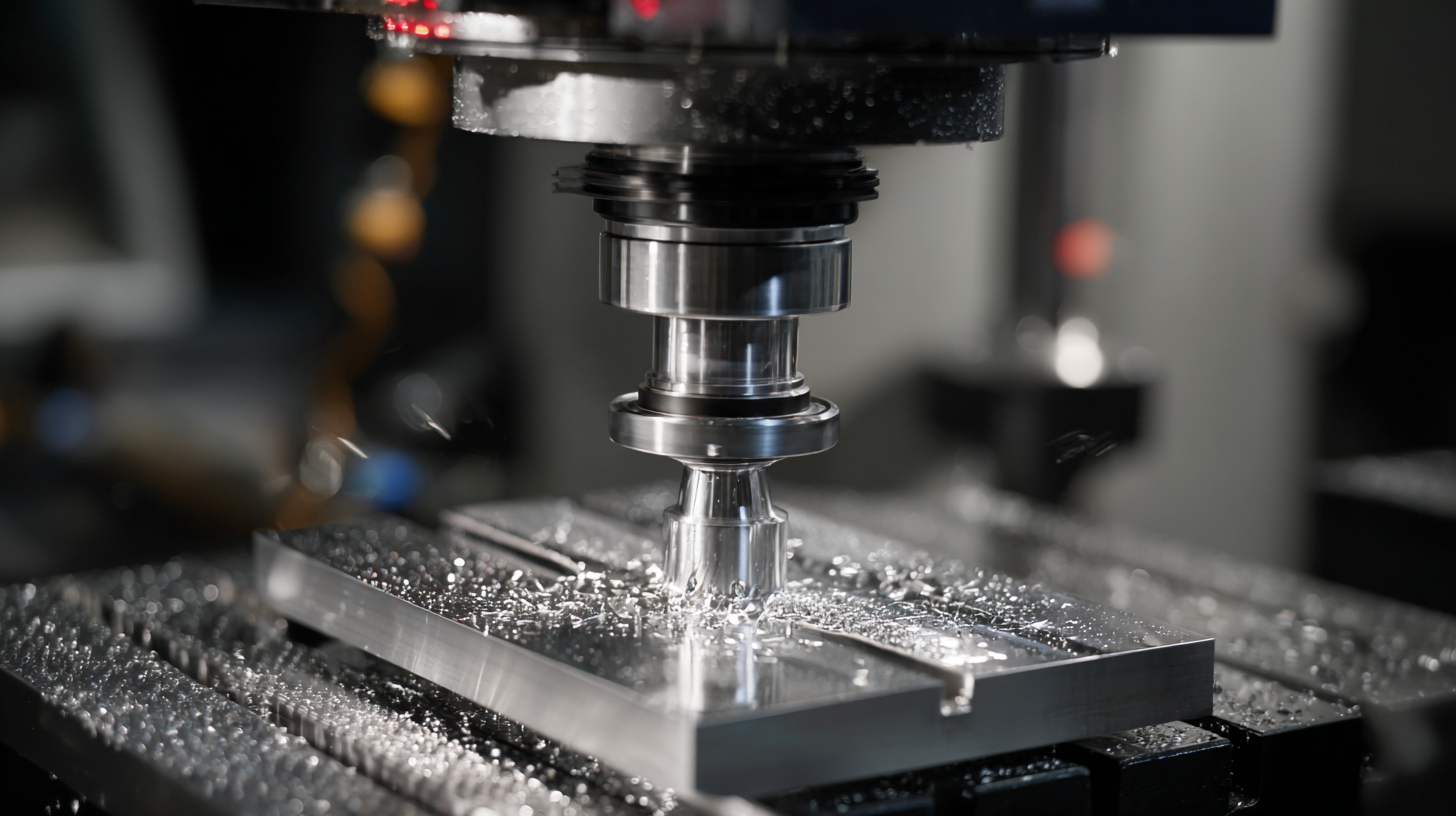

When evaluating the performance metrics of different CNC milling machines, key factors such as precision, speed, and operational versatility must be taken into account. According to a recent industry report by MarketsandMarkets, the global CNC machine tool market is projected to reach $100.3 billion by 2025, driven by the increasing demand for high-performance machinery capable of producing complex parts with minimal human intervention. Precision is often measured in micrometers, and top-tier desktop CNC mills typically offer tolerances as tight as ±0.01 mm, making them suitable for high-stakes applications in sectors like aerospace and medical manufacturing.

Tip: When assessing CNC machines, consider the spindle speed and feed rate, as these directly impact productivity. Higher spindle speeds—often exceeding 20,000 RPM in advanced models—enable faster material removal rates, which can significantly enhance overall machining efficiency. Additionally, versatility in tooling options—such as the ability to exchange tools automatically—can further streamline production processes and reduce downtime.

Furthermore, an evaluation of user feedback on performance can provide vital insights. A survey conducted by the International Manufacturing Technology Show (IMTS) revealed that over 60% of users prioritize ease of use and reliability when selecting CNC machines. Understanding these metrics can help global buyers identify the best desktop CNC milling machine that meets their specific manufacturing needs while ensuring optimal performance.

Case Studies: Successful Implementations of Desktop CNC Solutions

In the world of desktop CNC milling, case studies provide invaluable insights into successful implementations that highlight the versatility and efficiency of these machines. One notable case study involved a small jewelry manufacturer that adopted a high-precision desktop CNC milling machine to enhance their production capabilities. By leveraging the machine's advanced software and tooling options, the company was able to reduce production time by 30%, while also improving the quality of their intricate designs. This not only led to increased customer satisfaction but also opened avenues for new product lines, showcasing how a robust CNC solution can impact a niche market significantly.

Another example comes from an educational institution that integrated desktop CNC milling machines into their engineering curriculum. Students were able to engage in hands-on projects that instructed them on real-world manufacturing processes. This case revealed the ability of desktop CNC milling machines to streamline educational practices and foster creativity among students. By transitioning from traditional methods to modern CNC technology, the institute not only enhanced its teaching methodology but also better prepared students for careers in design and manufacturing. Such successful cases emphasize the importance of understanding and implementing the right manufacturing standards, ensuring that global buyers can make informed decisions for their specific needs.