Mastering Precision: How Desktop CNC Lathes Revolutionize Hobbyist Machining Projects

In recent years, the hobbyist machining landscape has experienced a remarkable transformation, largely driven by the advent of the Desktop CNC Lathe. According to a report by the International Association of Machinists and Aerospace Workers, the hobbyist machining sector has seen a growth rate of over 15% annually, fueled by advances in technology and the increasing accessibility of sophisticated tools.

Desktop CNC Lathes, once confined to professional workshops, now empower enthusiasts to undertake complex projects with unprecedented precision and efficiency. Industry data highlights that user-friendly design coupled with enhanced capabilities has attracted a broader audience, making precision machining more attainable than ever. As more hobbyists explore the capabilities of Desktop CNC Lathes, the impact on creative manufacturing and custom artistry becomes profoundly evident, signaling a new era in personal machining projects.

Desktop CNC Lathes, once confined to professional workshops, now empower enthusiasts to undertake complex projects with unprecedented precision and efficiency. Industry data highlights that user-friendly design coupled with enhanced capabilities has attracted a broader audience, making precision machining more attainable than ever. As more hobbyists explore the capabilities of Desktop CNC Lathes, the impact on creative manufacturing and custom artistry becomes profoundly evident, signaling a new era in personal machining projects.

Understanding Desktop CNC Lathes: Features and Benefits for Hobbyists

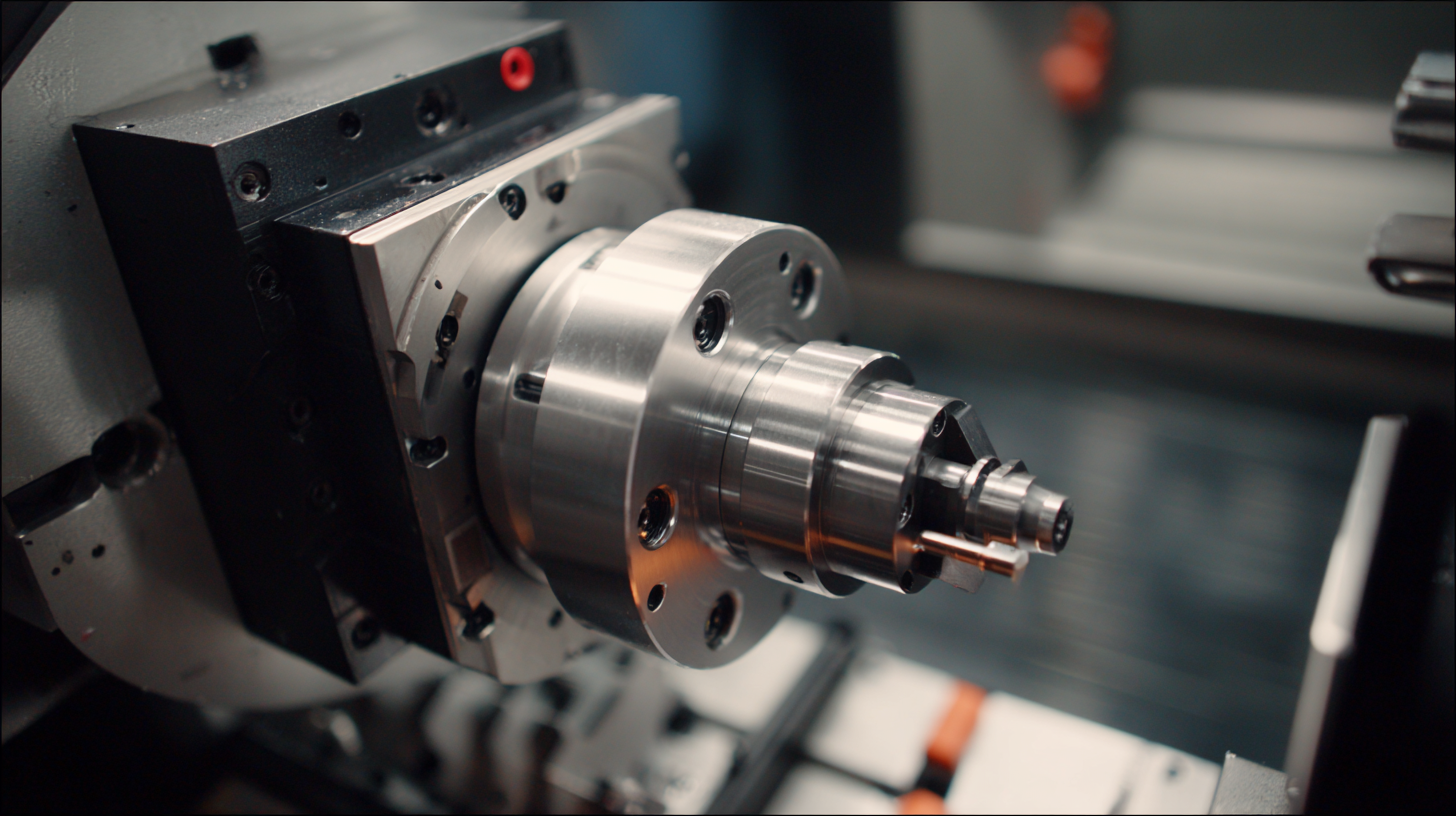

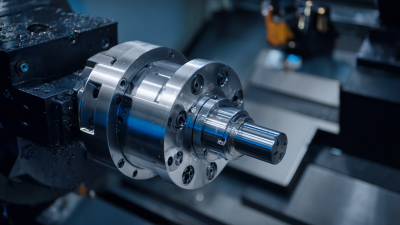

Desktop CNC lathes have transformed the landscape of hobbyist machining, making high-precision fabrication accessible to anyone with a passion for creation. These compact machines, designed to fit conveniently on a desk,

offer a remarkable range of features that empower users to undertake projects that were once the domain of large, expensive industrial equipment. With capabilities for cutting, engraving, and milling various materials like aluminum and wood, hobbyists can explore their creativity without the need for a professional workshop.

Desktop CNC lathes have transformed the landscape of hobbyist machining, making high-precision fabrication accessible to anyone with a passion for creation. These compact machines, designed to fit conveniently on a desk,

offer a remarkable range of features that empower users to undertake projects that were once the domain of large, expensive industrial equipment. With capabilities for cutting, engraving, and milling various materials like aluminum and wood, hobbyists can explore their creativity without the need for a professional workshop.

The benefits of desktop CNC lathes extend beyond their size. They provide intuitive interfaces and often come equipped with advanced software that simplifies the design and machining process. This user-friendly approach encourages newcomers to delve into the world of CNC machining, while seasoned makers can refine their skills and produce intricate designs. As the market for these machines grows, many manufacturers are aiming to support hobbyists in seamlessly transitioning their projects from personal endeavors to small-scale manufacturing, fostering a vibrant community of makers and innovators.

Essential Tools and Accessories for Maximizing Your CNC Lathe Experience

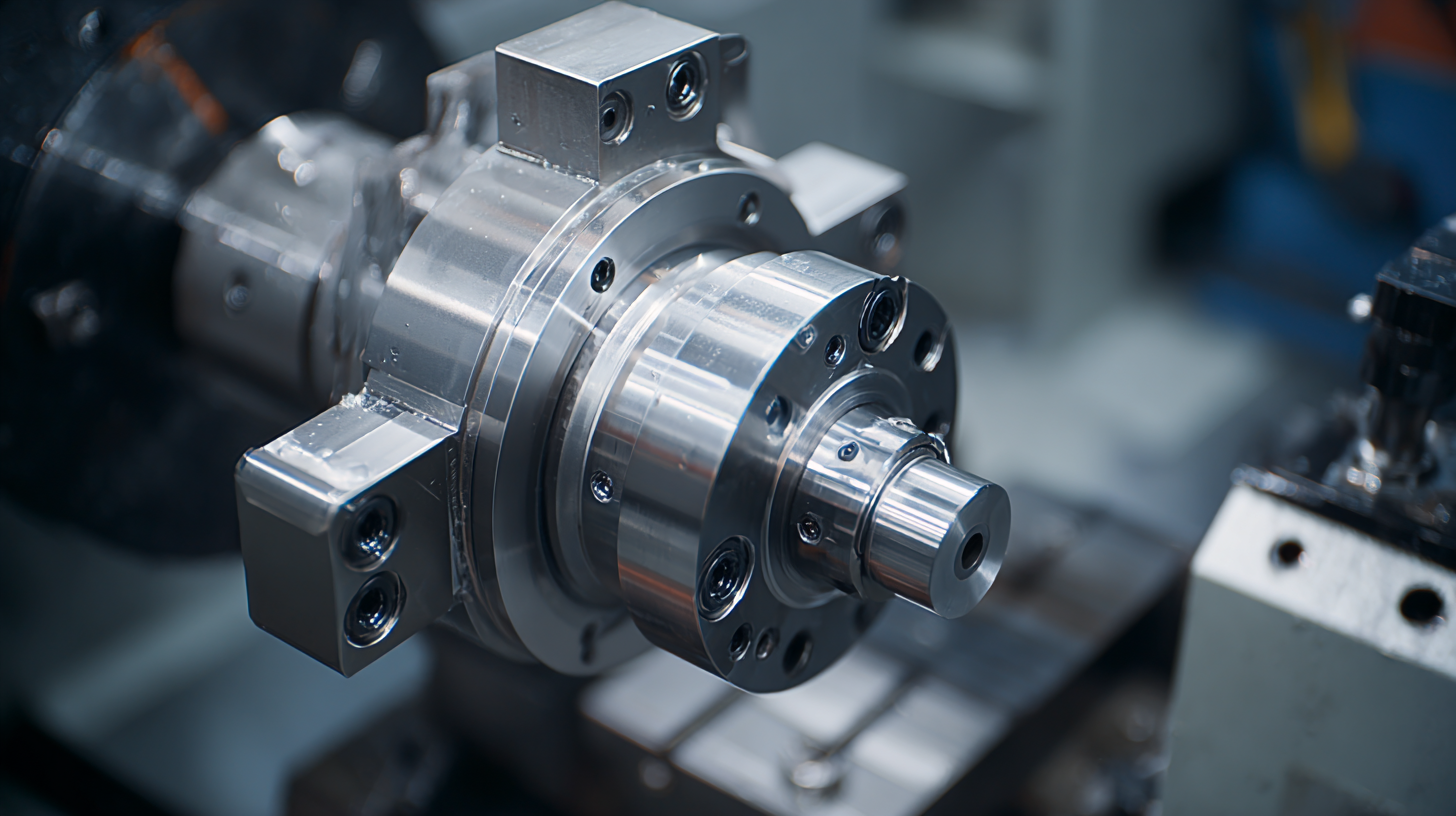

When diving into the world of desktop CNC lathes, understanding the essential tools and accessories can significantly enhance the machining experience. According to a report by Research and Markets, the global CNC machine market is projected to reach $100 billion by 2025, underlining the increasing popularity and accessibility of CNC technology among hobbyists. To get the most out of your CNC lathe, it’s important to invest in quality tools such as precision cutting tools, tool holders, and measuring devices. High-speed steel (HSS) and carbide bits are essential for achieving smooth finishes on various materials, and using the right tool holder ensures improved stability and reduced vibration during operation.

Additionally, accessories like digital readouts (DRO) and coolant systems can transform your setup into a more efficient workspace. According to a study by Statista, the demand for CNC accessories has risen by over 15% in recent years as enthusiasts seek to emulate professional machining standards. Implementing a DRO enhances accuracy, while a dedicated coolant system extends tool life and improves cutting performance. Together, these tools and accessories not only enhance the precision of hobbyist projects but also elevate the overall machining experience, reflecting the advancements and accessibility of desktop CNC technology.

Step-by-Step Guide to Setting Up Your Desktop CNC Lathe

Setting up a desktop CNC lathe can be an exciting yet daunting task for hobbyists, but with the right approach, it can lead to incredible precision in machining projects. According to a report by the Association for Manufacturing Technology, the desktop CNC machine market is expected to grow by 12% annually, highlighting the increasing popularity and accessibility of these tools for enthusiasts. First, start by selecting a suitable workspace—ensure that it is stable, clean, and has sufficient ventilation. This environment is critical for the longevity of your equipment and safety during operation.

Next, unpack your CNC lathe and organize all the necessary components. Typically, this includes the lathe itself, power supply, control software, and an assortment of cutting tools. Referencing the "Desktop CNC Machining Market Trends" report, a well-optimized setup can enhance workflow efficiency by up to 25%, indicating how vital proper configuration is. After ensuring all connections are secure, install the software on your computer and familiarize yourself with the interface. Many manufacturers provide detailed user manuals and online tutorials that can guide you through initial settings, calibration processes, and troubleshooting tips. Following these steps not only sets a robust foundation for your projects but also maximizes the accuracy and results of your machining endeavors.

Desktop CNC Lathe Usage in Hobbyist Projects

Techniques for Precision Machining: Tips for Hobbyist Projects

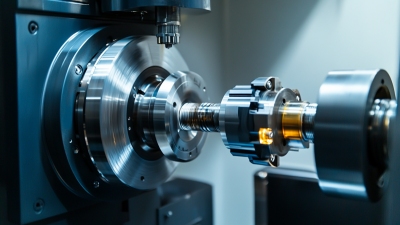

Desktop CNC lathes have transformed the landscape of hobbyist machining by enabling unparalleled precision in crafting intricate projects. With the rise of affordable and user-friendly models, hobbyists now have access to tools that were once confined to professional workshops. According to a report from the Association for Manufacturing Technology, the CNC market is projected to grow steadily, with significant increases in the hobbyist segment driven by advancements in technology and accessibility. This shift empowers enthusiasts to tackle complex projects that require a level of accuracy previously deemed unattainable.

To master precision machining with a desktop CNC lathe, several techniques can significantly enhance your project outcomes. Start by investing in quality cutting tools, as they are crucial for achieving clean and accurate cuts. Regular maintenance of your CNC machine is equally important; a well-oiled and calibrated machine performs better and extends your tool's lifespan. Incorporating proper design software can also streamline your workflow, allowing for precise measurements and adjustments that ensure your final pieces meet your expectations. As noted in industry data, hobbyists who adopt these practices not only improve their skills but also elevate the quality of their work, leading to more successful and satisfying projects.

Common Mistakes to Avoid When Using a Desktop CNC Lathe

When diving into the world of desktop CNC lathes, hobbyists often encounter several pitfalls that can derail their projects. One common mistake is overlooking the importance of

proper setup. Before beginning any machining task, ensuring that the lathe is calibrated accurately and all components are

securely fastened is crucial. An improperly set up machine can lead to inaccurate cuts and wasted materials, ultimately costing time and resources.

Another frequent error is neglecting to perform regular maintenance on the lathe. Dust and debris can accumulate, affecting the precision of cuts and the overall performance of the machine.

Hobbyists should develop a maintenance schedule, including cleaning and lubricating parts, to keep their equipment in top shape. Additionally, lacking a solid understanding of materials can lead to choosing the wrong tools and

settings. Each material reacts differently under machining conditions, and misjudging this can result in subpar finishes or, worse, machine damage. By being mindful of these common mistakes, hobbyists can enhance their experience and

achieve more successful outcomes with their CNC lathe projects.

Related Posts

-

Transforming Manufacturing: 2025 Innovations in CNC Turning Machines & Buyer’s Guide

-

Unlocking Precision: Tips to Choose the Right Desktop CNC Lathe for Your Manufacturing Needs

-

Future Trends in CNC Turning Machines and Global Market Comparisons for 2025

-

Finding Quality Suppliers for Best Cnc Turning Machine with Proven Strategies and Insights

-

Elevate Your Manufacturing with China’s Premier Desktop CNC Lathes: A Global Standard

-

Ultimate Guide to Your Best Small Cnc Lathe Purchase Checklist