How to Maximize Efficiency with a Multi Axis CNC Machine for Your Projects

In today's fast-paced manufacturing environment, optimizing production efficiency is more crucial than ever, and one of the best solutions available is the Multi Axis CNC Machine. According to a report by MarketsandMarkets, the global CNC machine market is expected to reach $100 billion by 2026, with a significant shift towards multi-axis machines due to their versatility and precision.

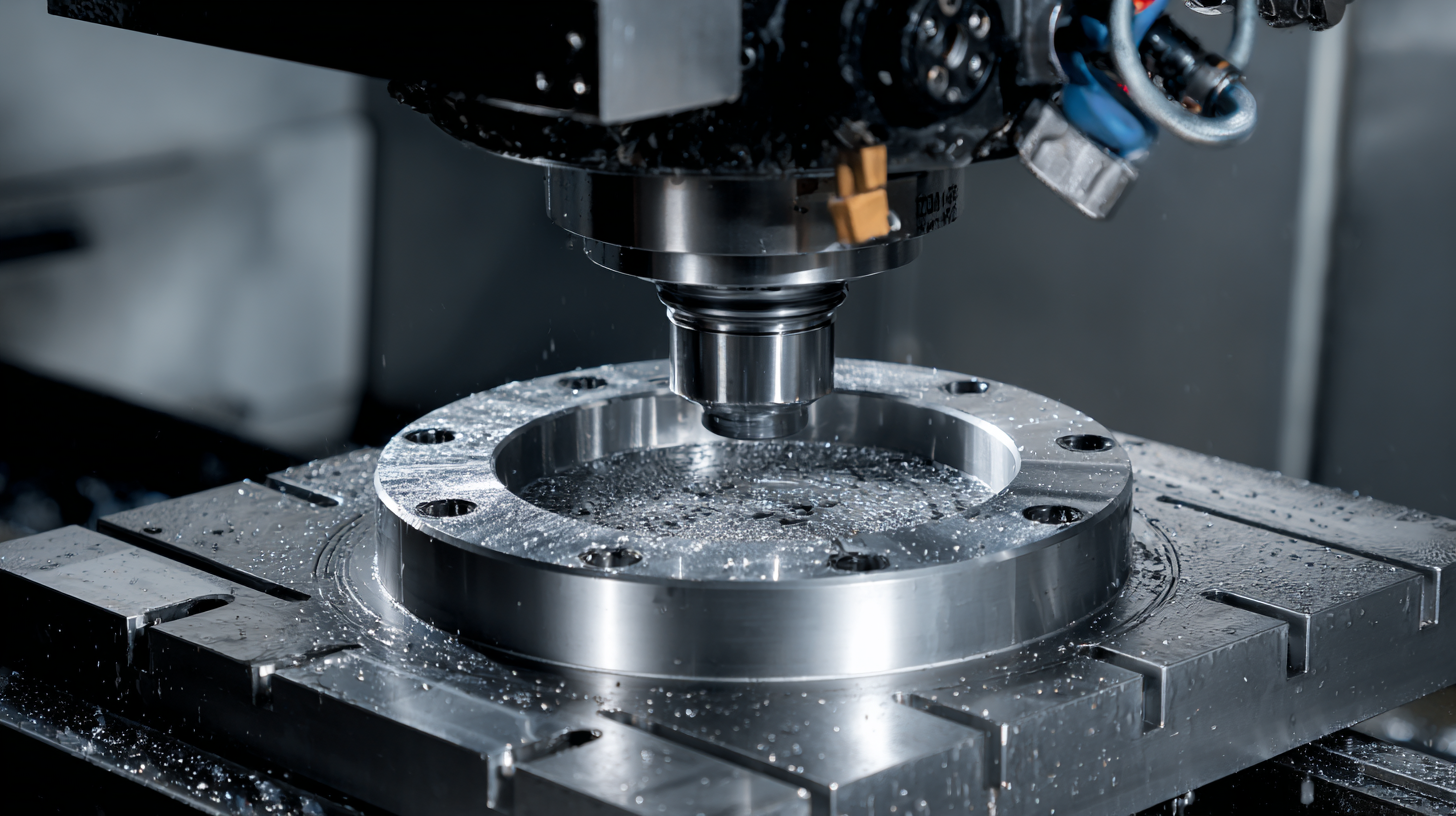

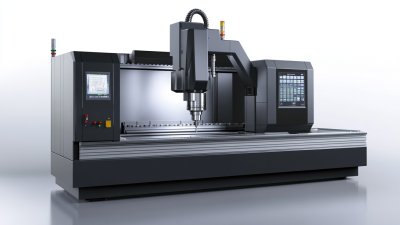

Multi Axis CNC Machines can mill, turn, and drill parts with intricate geometries in a single setup, reducing cycle times and increasing throughput. Studies indicate that companies integrating multi-axis technology have seen efficiency improvements of up to 30%, which is essential in competitive industries like aerospace and automotive. By leveraging the capabilities of Multi Axis CNC Machines, manufacturers can not only enhance their productivity but also achieve higher quality output, making it a vital consideration for modern machining projects.

Benefits of Multi-Axis CNC Machines in Modern Manufacturing Efficiency

Multi-axis CNC machines are revolutionizing modern manufacturing by enhancing efficiency through their advanced capabilities. Unlike traditional CNC machines, which typically operate on three axes, multi-axis systems can pivot and rotate, allowing for more complex geometries and designs to be produced in a single setup. This not only cuts down on production time but also minimizes the need for multiple setups, reducing potential errors that can occur when transferring workpieces between machines.

The benefits extend beyond just time savings. Multi-axis CNC machines lead to improved precision and quality in the final products. With the ability to reach intricate angles and tight tolerances, manufacturers can create more intricate components that are often impossible to achieve with simpler machines. Additionally, the versatility of these machines allows for greater flexibility in production, accommodating a wider variety of materials and designs. As a result, businesses leveraging multi-axis technology find themselves better equipped to meet the demands of a competitive market while still controlling costs.

Understanding the Key Performance Indicators for CNC Machining

When utilizing a multi-axis CNC machine, understanding key performance indicators (KPIs) is crucial for maximizing efficiency throughout your projects. KPIs in CNC machining typically include aspects such as cycle time, accuracy, repeatability, and machine utilization. Each of these metrics provides insights that can help refine production processes, reduce waste, and ensure high-quality output.

**Tip:** Regularly monitor cycle time to identify bottlenecks in your machining processes. A well-optimized cycle time not only reduces lead times but also enhances productivity.

Another critical KPI is accuracy, which measures how closely parts match their specified dimensions. Maintaining a high level of accuracy minimizes rework and scrap, ultimately saving time and materials. Additionally, repeatability affects how consistently a CNC machine can produce parts over multiple runs.

**Tip:** Invest in proper maintenance and calibration of your CNC machine to ensure sustained accuracy and repeatability throughout its operational lifespan.

By focusing on these KPIs, manufacturers can make informed decisions to enhance the efficiency of their multi-axis CNC operations and achieve better overall project outcomes.

Strategies for Optimizing Tool Path Design in Multi-Axis Operations

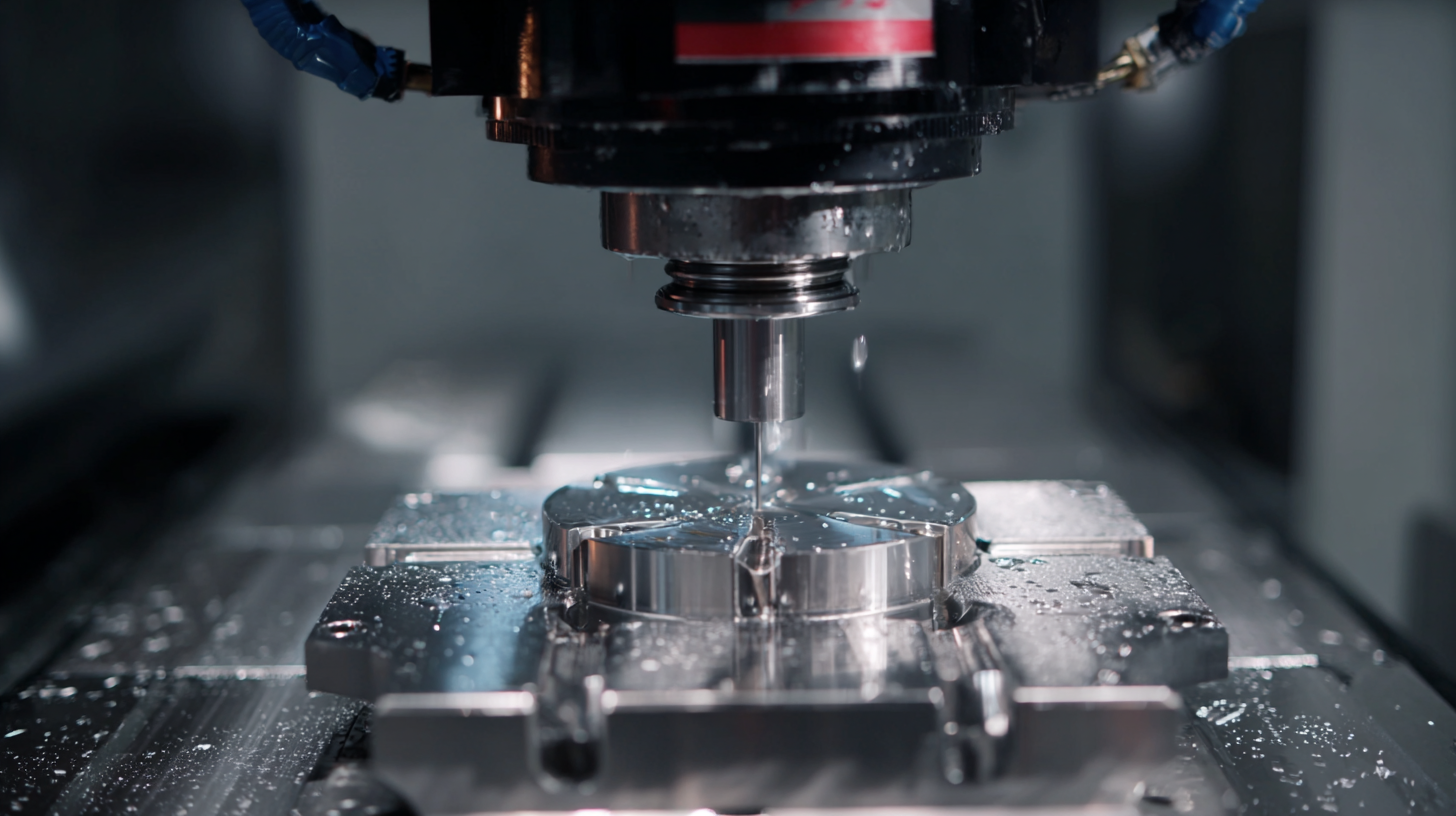

In multi-axis CNC machining, optimizing tool path design is crucial to enhance machining efficiency and precision. One effective strategy is to leverage advanced software that allows for simulation and visualization of the tool path. By using these tools, operators can identify potential collisions and inefficiencies in the design before actual machining begins. This proactive approach not only saves time and resources but also ensures higher quality finishes by minimizing tool wear and maximizing feed rates.

In multi-axis CNC machining, optimizing tool path design is crucial to enhance machining efficiency and precision. One effective strategy is to leverage advanced software that allows for simulation and visualization of the tool path. By using these tools, operators can identify potential collisions and inefficiencies in the design before actual machining begins. This proactive approach not only saves time and resources but also ensures higher quality finishes by minimizing tool wear and maximizing feed rates.

Another strategy involves utilizing adaptive tool path strategies that take into account the geometry of the workpiece and the capabilities of the CNC machine. Implementing techniques such as continuous path control can significantly reduce cycle times by allowing smoother transitions between cuts. Furthermore, understanding the specific cutting tools and their optimal operating conditions—like speed and feed—can greatly influence the effectiveness of the machining process. By focusing on these aspects, manufacturers can maximize the full potential of multi-axis CNC machines, leading to improved productivity and cost savings in machining operations.

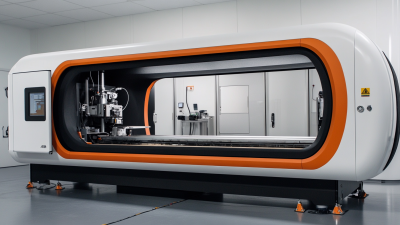

Integrating Automation Technologies to Enhance Multi-Axis Machine Workflow

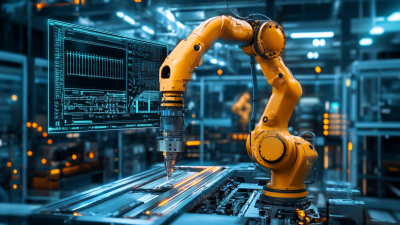

Integrating automation technologies within multi-axis CNC machining workflows can significantly enhance operational efficiency and precision. According to a report by MarketsandMarkets, the CNC machine market is projected to grow to $100 billion by 2025, driven largely by advancements in automation and smart manufacturing solutions. By integrating automation technologies such as robotics and AI-driven software, manufacturers can increase production speed by up to 30%, while reducing errors associated with manual operations.

Moreover, automation allows for improved workflow management, maximizing the capabilities of multi-axis CNC machines. A study by Deloitte highlights that companies implementing automation have seen a 20% reduction in lead times and a 50% decrease in downtime. This proves crucial for projects that demand high adaptability and a quick turnaround. By utilizing automated tools like predictive maintenance and real-time monitoring systems, manufacturers can ensure consistent operational efficiency and maintain optimal machine performance, ultimately leading to higher quality outputs and increased customer satisfaction.

Analyzing Cost Savings through Increased Production Speed with Multi-Axis CNC

Maximizing efficiency with a multi-axis CNC machine is essential in today’s fast-paced manufacturing environment. By leveraging the capabilities of these advanced machines, companies can significantly enhance their production speed, leading to substantial cost savings. Reports suggest that the global precast concrete market is projected to grow from $151.49 billion in 2024 to approximately $246.07 billion by 2032. This growth demonstrates a vital opportunity for manufacturers to adopt multi-axis CNC technology to meet increasing demand while simultaneously reducing operational expenses.

The integration of multi-axis CNC machines allows for complex geometries to be machined in a single setup, resulting in fewer errors and reduced cycle times. In addition, as manufacturers face declining prices in raw materials—such as wheat in the Midwest—optimizing production processes becomes increasingly critical to maintaining profitability. By enhancing production efficiency through advanced machining techniques, companies can better navigate market fluctuations and sustain their competitive edge in a challenging economic landscape.

Production Speed vs. Cost Savings with Multi-Axis CNC Machines

This chart illustrates the relationship between production speed and cost savings achieved through the use of multi-axis CNC machines. As production speed increases, cost savings also rise, demonstrating the efficiency benefits of advanced CNC technology.

Related Posts

-

10 Reasons Axis Cnc is Revolutionizing the Manufacturing Industry

-

Transforming Manufacturing: 2025 Innovations in CNC Turning Machines & Buyer’s Guide

-

Optimizing Maintenance Costs and Enhancing After Sales Support for Cnc Precision Parts

-

Exploring Cnc Machine Technologies Shaping the Future of Global Manufacturing by 2025

-

Evaluating CNC Parts: Key Factors That Distinguish Quality Suppliers

-

Finding Reliable Suppliers for Your Cnc Machine Tools Needs