Precision CNC Machining vs Traditional Manufacturing A Comprehensive Analysis of Efficiency and Cost Effectiveness

As the manufacturing landscape continues to evolve, the debate between Precision CNC Machining and traditional manufacturing methods becomes increasingly relevant. According to a report by the International Federation of Robotics, the global market for CNC machines is expected to grow at a CAGR of 7.2%, reaching $79 billion by 2027, underscoring the rising adoption of advanced machining technologies. Precision CNC Machining offers significant advantages in terms of efficiency and cost-effectiveness, providing manufacturers with the ability to produce complex parts with high accuracy while minimizing waste. In contrast, traditional manufacturing methods often involve longer production times and higher labor costs, making them less competitive in today’s fast-paced market. This comprehensive analysis will delve into the key differences between these two manufacturing approaches, highlighting the transformative impact of Precision CNC Machining on the industry and offering solutions tailored to modern production demands.

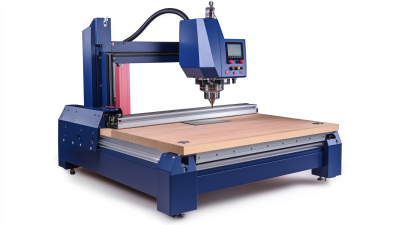

Precision CNC Machining: An Overview of Modern Manufacturing Techniques

Precision CNC machining has revolutionized modern manufacturing techniques by providing unparalleled accuracy and efficiency. Unlike traditional manufacturing methods that often rely on manual labor and time-consuming setups, CNC (Computer Numerical Control) machines automate the process, significantly reducing production times. A study by the National Institute of Standards and Technology reported that companies employing CNC machining can achieve up to 50% greater accuracy compared to their traditional counterparts. This precision not only elevates product quality but also minimizes material waste, thus optimizing overall costs.

**Tip:** When considering a transition to CNC machining, it’s crucial to evaluate the initial investment against long-term savings. Investing in high-quality CNC machines can lead to a 30% reduction in labor costs and a drastic improvement in output quality.

Furthermore, CNC machining offers flexibility that is essential in today’s fast-paced market. Manufacturers can quickly alter designs or switch between different products without extensive retooling processes, which often plague traditional methods. According to a report by MarketsandMarkets, the CNC machine market is projected to reach $117.16 billion by 2026, highlighting its increasing role in manufacturing efficiency.

**Tip:** To maximize the benefits of CNC technology, ensure that your staff is well-trained in both operating the equipment and in understanding CAD (Computer-Aided Design), as this pairing is vital for achieving optimal results in precision machining.

Precision CNC Machining vs Traditional Manufacturing

This chart illustrates the comparison of efficiency and cost-effectiveness between Precision CNC Machining and Traditional Manufacturing methods based on various production factors.

Comparative Efficiency: CNC Machining vs. Traditional Methods in Production Time

In the ongoing debate between precision CNC machining and traditional manufacturing methods, efficiency in production time emerges as a critical factor. CNC machining, with its automated capabilities, significantly reduces the lead time compared to manual processes. This is particularly evident in complex parts production, where CNC machines excel at maintaining tight tolerances and repeatability. The integration of advanced software and robotic automation further streamlines operations, making it possible to produce intricate designs with minimal downtime.

Conversely, traditional manufacturing techniques often rely on manual labor and slower, more labor-intensive processes. While these methods can be cost-effective for low-volume production, they struggle to match the speed and precision achieved by CNC machining in high-demand scenarios. Studies show that time efficiency can improve by over 50% when utilizing CNC technology, allowing manufacturers to respond rapidly to market changes. As industries seek to optimize production cycles and enhance competitiveness, the shift towards CNC machining is increasingly favored for its ability to merge efficiency with cost-effectiveness.

Cost Analysis: Understanding Material Waste and Labor Costs in Manufacturing

In the realm of manufacturing, cost analysis plays a critical role in determining the efficiency and sustainability of production methods. When comparing precision CNC machining to traditional manufacturing techniques, material waste is a significant factor. According to industry reports, CNC machining can reduce material waste by up to 80% compared to traditional methods. This reduction stems from the precise cutting capabilities of CNC machines, which allow for tighter tolerances and optimized material utilization.

Labor costs also present a stark contrast between these two manufacturing processes. Traditional manufacturing often relies on labor-intensive techniques that incur higher wage expenses and longer production times. In contrast, CNC machining automates processes, thus reducing labor involvement and minimizing human error. Reports indicate that companies see a labor cost reduction of up to 30% when switching to CNC machining, leading to quicker turnaround times and improved profitability. These efficiencies not only benefit the bottom line but also contribute to a more sustainable manufacturing model by minimizing waste and maximizing productivity.

Precision CNC Machining vs Traditional Manufacturing: A Comprehensive Analysis of Efficiency and Cost Effectiveness

| Manufacturing Method | Material Waste (%) | Labor Cost per Hour ($) | Average Production Time (hrs) | Setup Cost ($) |

|---|---|---|---|---|

| Precision CNC Machining | 3% | 25 | 1 | 500 |

| Traditional Manufacturing | 10% | 20 | 5 | 300 |

| Hybrid Manufacturing | 5% | 30 | 3 | 600 |

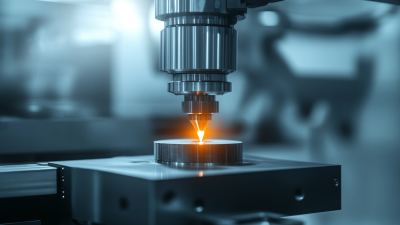

Precision Levels: How CNC Machining Achieves Tighter Tolerances Than Traditional Approaches

CNC machining has revolutionized the manufacturing industry by providing precision levels that far exceed those of traditional methods. This technology utilizes computerized controls to manipulate cutting tools, enabling the production of complex parts with tighter tolerances. In fields such as medical device manufacturing, where the demand for smaller, highly functional components is ever-increasing, CNC machining ensures that parts are fabricated with immaculate precision. The use of advanced techniques, such as laser processing alongside traditional machining, further enhances these capabilities, making it possible to meet rigorous industry standards.

As the industry evolves, the significance of precision in manufacturing cannot be overstated. Companies require faster verification of parts and the ability to measure dimensions more accurately than ever before. This shift is not only driven by technological advancements but also by market demands for quality and efficiency. Solutions like the integration of modern sensor systems in grinding operations and innovations in micromachining techniques allow manufacturers to achieve unparalleled accuracy. Consequently, CNC machining remains at the forefront of manufacturing, setting a new benchmark for quality management while addressing the needs of various sectors, from healthcare to automotive and beyond.

Industry Trends: Growth Projections for CNC Machining in the Manufacturing Sector

The manufacturing sector is on the cusp of significant transformation, driven by the increasing adoption of CNC (Computer Numerical Control) machining techniques. As industries seek higher precision, versatility, and automation, CNC machining is projected to experience considerable growth over the next decade. According to market analyses, the demand for CNC machinery is expected to rise sharply, fueled by advancements in technology that allow for more intricate designs and faster production times. This trend highlights the shift in focus from traditional manufacturing methods to more sophisticated, computer-driven processes.

Moreover, the efficiency of CNC machining presents a compelling case for its adoption. Unlike traditional manufacturing, which often requires extensive manual labor and setup time, CNC machines operate based on pre-programmed computer software, vastly reducing production cycles and minimizing human error. As manufacturers increasingly prioritize operational efficiency and cost-effectiveness, CNC machining emerges as a key player in meeting these goals. Companies that capitalize on this trend not only enhance their production capabilities but also position themselves competitively in a rapidly evolving market landscape.

Related Posts

-

Exploring Top Strategies to Source Reliable Home Cnc Machine Suppliers Globally

-

Ultimate Comparison of Best Cnc Machine Tools for Precision Manufacturing in 2023

-

Built on Trust Best Axis Cnc from a Leading Chinese Factory

-

Ultimate Guide to Sourcing the Best CNC Precision Parts: Key Insights and Industry Trends

-

Ultimate Checklist for Choosing the Right Industrial CNC Machine for Your Business

-

5 Reasons Why Axis CNC Machines Boost Manufacturing Efficiency by 40 Percent