Finding Reliable Suppliers for Your Cnc Machine Tools Needs

In the ever-evolving world of manufacturing, maintaining a competitive edge requires access to high-quality Cnc Machine Tools. Whether you are a seasoned industry professional or a newcomer to the field, finding reliable suppliers is crucial to your success. The performance and longevity of your CNC machinery depend not only on the machines themselves but also on the quality of the tools and components used within them. This blog will guide you through the essential steps in sourcing trustworthy suppliers who can meet your specific needs for CNC machine tools.

Selecting the right suppliers is more than just a transaction; it is an investment in the efficiency and effectiveness of your operations. As manufacturing demands grow, the importance of finding suppliers who understand the intricacies of Cnc Machine Tools and can offer tailored solutions cannot be overstated. In the following sections, we will explore key strategies for evaluating potential suppliers, ensuring you choose partners who can support your production goals and enhance your overall performance in the increasingly competitive landscape of modern manufacturing.

Understanding the Importance of Reliable Suppliers for CNC Machine Tools

In the world of CNC machining, the reliability of suppliers plays a crucial role in the success of any operation. CNC machine tools are integral to producing precise components and delivering quality products, and choosing the right suppliers can significantly impact production efficiency and overall business performance. Reliable suppliers ensure that you receive not only high-quality machinery but also consistent support and timely delivery, which are essential for maintaining productivity and meeting customer demands. Understanding the importance of reliable suppliers goes beyond just the tools themselves. A dependable supplier acts as a business partner, offering insights into industry trends, new technologies, and best practices. This collaboration fosters innovation and helps companies stay competitive in a rapidly evolving market. Furthermore, reliable suppliers are often better at managing inventory and can provide emergency support when machinery malfunctions, reducing downtime and minimizing losses. Additionally, working with established suppliers often means access to a larger network of resources, including spare parts and maintenance services. This facilitates smoother operations and ensures that your CNC machines continue to function at optimal levels. Ultimately, the choice of supplier can make or break a business's efficiency, making it imperative to invest the time and effort into finding a trustworthy partner for your CNC machine tool needs.

Key Qualities to Look for in a CNC Tool Supplier

When searching for reliable suppliers for your CNC machine tools needs, it's crucial to identify the key qualities that can define a strong partnership. One of the most important attributes is experience within the industry. A supplier with a proven track record demonstrates not only their expertise but also their ability to anticipate and address potential issues that may arise during the procurement process. Look for suppliers who have been in the market for several years and have accumulated substantial knowledge regarding different types of CNC tools and their applications.

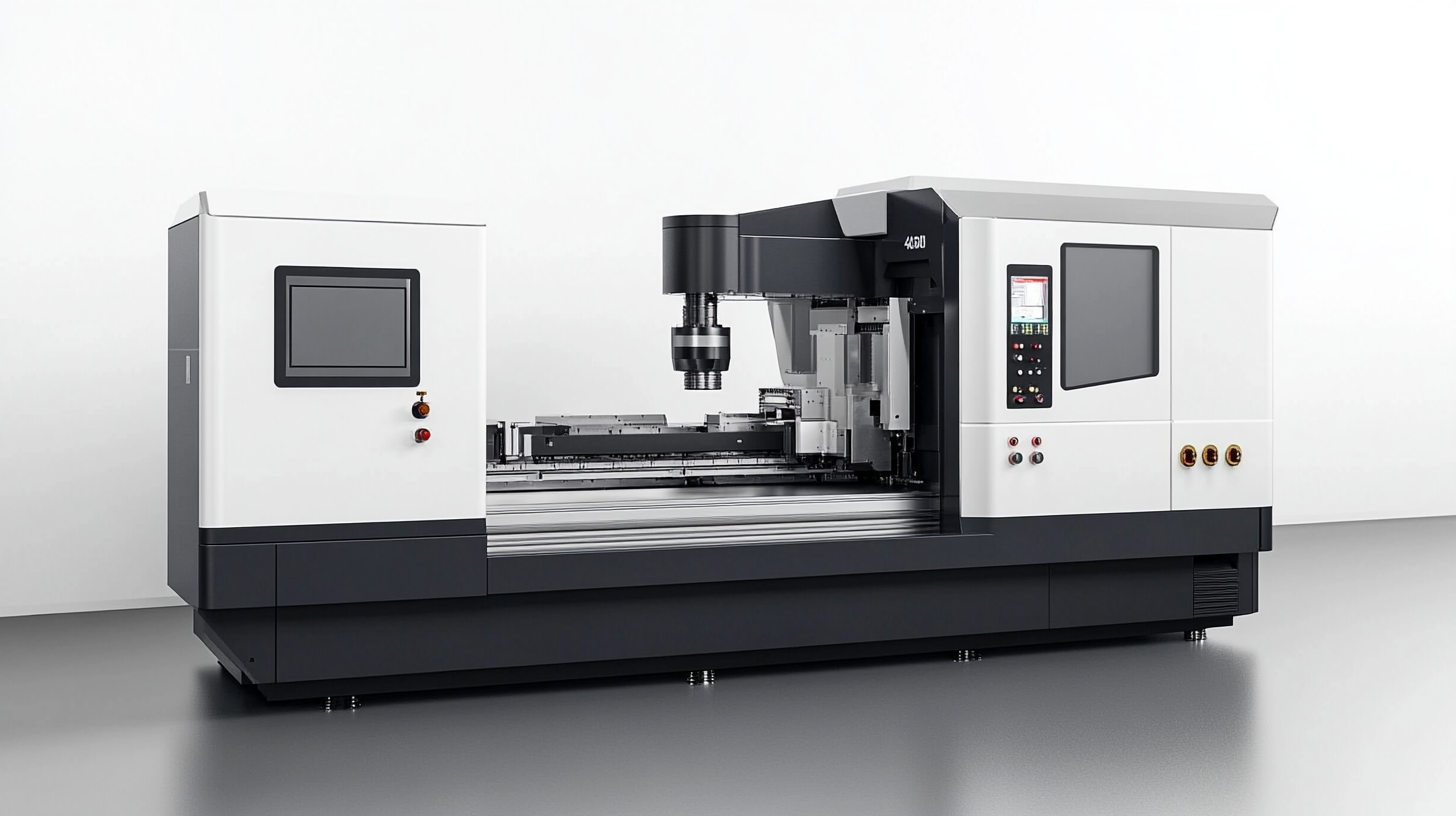

Another essential quality is the supplier's product range and technological capabilities. A versatile supplier should offer a variety of CNC machine tools, including lathes, mills, and routers, along with relevant accessories and parts. This diversity indicates their ability to support a wide range of projects and customer needs. Moreover, suppliers who leverage the latest technology and innovations are more likely to provide high-quality and efficient tools that can enhance productivity in your operations.

Additionally, strong customer service and support are vital traits to consider. A reliable supplier should be responsive and approachable, offering timely assistance for any inquiries or issues that may arise. Look for suppliers who provide comprehensive technical support, including guidance on tool selection, maintenance, and troubleshooting. Establishing a good communication channel fosters a collaborative relationship and ensures you receive the assistance you need to optimize your CNC machining operations.

Evaluating Supplier Credentials and Certifications in the CNC Industry

In the CNC industry, selecting reliable suppliers is crucial for ensuring the quality and efficiency of your manufacturing processes. One of the primary steps in this evaluation is to scrutinize supplier credentials and certifications. According to the International Organization for Standardization (ISO), companies that are ISO 9001 certified demonstrate a commitment to quality management systems. This certification is particularly important in CNC machining, where precision and consistency are paramount. Approximately 70% of businesses report increased customer satisfaction after implementing ISO standards, revealing a direct correlation between certifications and supplier reliability.

Another critical certification to consider is the American National Standards Institute (ANSI) accreditation, which verifies that suppliers adhere to industry standards and regulations. An ANSI-certified supplier is likely to provide materials and services that meet the rigorous standards of the CNC machining environment. A joint report by the National Association of Manufacturers (NAM) and Deloitte found that manufacturers performing rigorous supplier evaluations, including credential assessments, have 20% higher operational efficiency compared to those who do not.

It's also essential to look at industry-specific certifications like the Society of Manufacturing Engineers (SME) certification, which ensures suppliers are knowledgeable about the latest CNC technologies and best practices. This is significant as advancements in CNC technology continue to evolve rapidly. A recent survey indicated that 60% of manufacturers prioritize suppliers with updated certifications, indicating that staying current with technological advancements can greatly enhance operational effectiveness and product quality.

Leveraging Reviews and Testimonials to Assess CNC Suppliers

When it comes to sourcing reliable suppliers for your CNC machine tools, leveraging reviews and testimonials is vital in today’s competitive manufacturing landscape. As small manufacturers increasingly turn to innovative technologies, including collaborative robots (cobots) and advanced CNC machines, the need for dependable suppliers has never been greater. Reviews provide insights into the experiences of other manufacturers who have utilized specific suppliers, allowing potential buyers to gauge the quality of products and services offered.

For instance, recent evaluations of entry-level CNC machines underscore the importance of user feedback. Products like the 3018 Pro CNC highlight how affordable tools can deliver surprising performance, which is often echoed in user testimonials that praise their functionality for tasks like prototyping and engraving. Additionally, reviews of multi-functional machines like the Snapmaker Artisan showcase the versatility that small manufacturers look for; insights from users can guide new buyers in making informed decisions based on real-world performance.

Furthermore, considering the rapidly evolving technology within the CNC and robotics sectors, testimonials can shed light on a supplier's ability to innovate and adapt. For example, the rise of low-cost CNC machines and advancements in robot-assisted manufacturing reveal the critical need for a supplier that not only provides quality tools but also embraces the latest technological trends. By focusing on reviews, manufacturers can assess whether a supplier is capable of meeting their unique needs for flexibility and reliability in a fast-paced production environment.

Building Long-Term Relationships with Your CNC Machine Tool Suppliers

Building long-term relationships with your CNC machine tool suppliers is crucial for maintaining a competitive edge in the manufacturing industry. Suppliers are more than just vendors; they are partners that contribute to your business's ability to innovate and meet the demands of the market. Establishing trust and open communication creates a collaborative environment where both parties can thrive. By engaging with suppliers early in the design phase and sharing your production needs and challenges, you can foster a deeper connection that often leads to tailored solutions that drive efficiency and reduce costs.

Moreover, as advancements in technology reshape the manufacturing landscape, selecting suppliers who are at the forefront of innovation is essential. For instance, suppliers who leverage artificial intelligence and automation in their operations can offer insights and equipment that enhance your production capabilities. Embracing this technological synergy not only streamlines your operations but also positions your business to adapt to shifting market demands effectively. Investing time in nurturing these relationships will pay dividends as your suppliers evolve, ensuring that your CNC machining needs are continually met with cutting-edge solutions.