What is a Rubber Pump Impeller and How Does It Work?

In the realm of fluid dynamics, the **Rubber Pump Impeller** stands as a vital component in various applications. It plays a crucial role in enhancing efficiency and performance in pumps across industries. According to a recent report by the Fluid Handling Experts Association, rubber impellers can increase pump efficiency by up to 15%. This statistic highlights the importance of quality materials in pump design.

Expert John Adams, a leading figure in pump technology, states, "The choice of impeller material fundamentally impacts fluid handling capabilities." His insights underline the significance of using rubber in impeller production. Rubber impellers not only resist wear but also absorb vibrations. This unique ability often leads to extended pump life.

However, flaws in design or material can lead to inefficiencies. For instance, selecting an inappropriate rubber compound may compromise performance. It’s essential to acknowledge the continuous need for innovation in the manufacturing process. Balancing durability with flexibility remains a challenge. The evolving market demands a heightened focus on optimizing rubber pump impellers for increasingly complex applications.

What is a Rubber Pump Impeller?

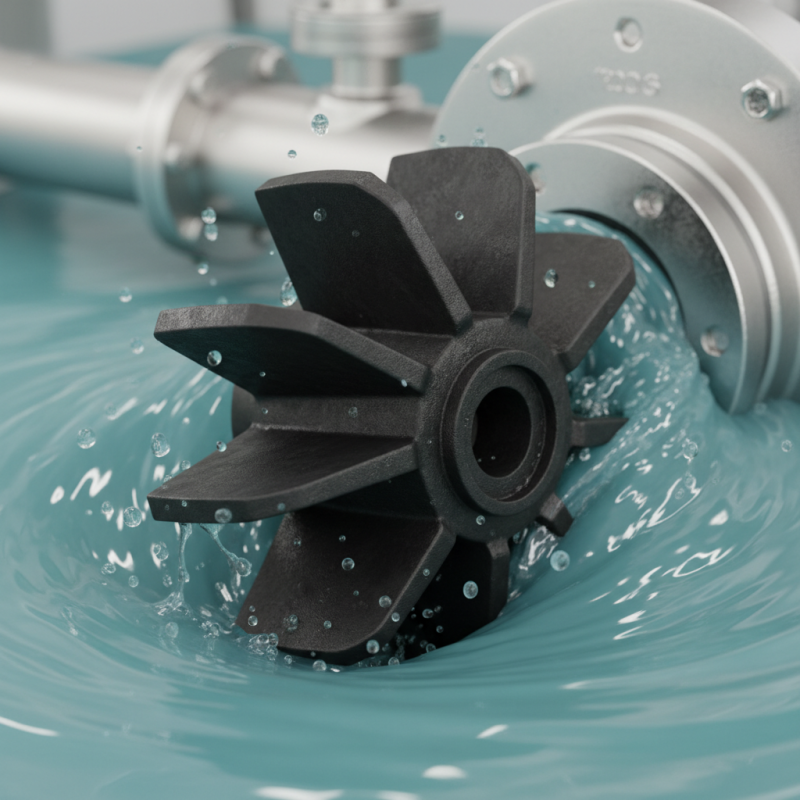

A rubber pump impeller is a crucial component in many pumping systems. It is often made from durable synthetic rubber materials that provide flexibility and resistance to wear. This allows the impeller to withstand harsh environments and various chemicals. Unlike metal impellers, rubber offers better protection against corrosion and abrasion, which can prolong the lifespan of the pump.

The impeller works by converting rotational energy into fluid movement. When the impeller spins, it creates a centrifugal force that pushes fluid outward. This action draws more fluid into the pump, maintaining a consistent flow. In some cases, the design of the impeller may lead to inefficiencies. If the blades are not shaped correctly, it can cause turbulence, reducing performance. Careful design considerations are necessary to maximize efficiency.

Maintenance is also essential for rubber pump impellers. Over time, the rubber can degrade, leading to reduced effectiveness. Regular inspection and replacement can improve the overall function of the pump. However, it’s easy to overlook this during routine tasks. This can lead to potential issues that might be costly down the line. Understanding both the advantages and limitations of rubber impellers can help in making better operational decisions.

The Functionality of a Rubber Pump Impeller

Rubber pump impellers play a crucial role in fluid dynamics. They are primarily designed to move fluids efficiently. The flexibility of rubber allows these impellers to seal better, reducing leakage. This tension contributes to higher efficiency in pumping systems.

According to a report by the Fluid Handling Association, rubber impellers can outperform metallic ones in corrosive environments. This is particularly beneficial in chemical processing and wastewater management. A well-functioning rubber impeller can lead to a significant reduction in operational costs. The plans for maintaining these parts should include regular inspections.

Tips: Always check for wear and tear. Small cracks can affect performance. Additionally, ensure that the impeller is free from debris to maintain optimal function. Regular maintenance is key to longevity. In some cases, operators overlook minor damages. However, even small issues can lead to larger problems down the line.

Performance of Rubber Pump Impellers

This chart illustrates the efficiency of rubber pump impellers at varying flow rates. The data represents the typical performance metrics of rubber pump impellers based on flow rate in gallons per minute (GPM) and the corresponding efficiency percentage.

Materials Used in Rubber Pump Impellers

Rubber pump impellers play a crucial role in various pumping systems. These components are typically made from durable rubber materials that provide both flexibility and resilience. Common materials include natural rubber, neoprene, and polyurethane. Each type has unique properties that cater to different applications. For example, neoprene offers excellent chemical resistance, making it suitable for aggressive fluids.

The choice of material impacts the impeller's performance. Natural rubber is efficient but may wear out quickly in harsh environments. Polyurethane, on the other hand, is tougher and can last longer under stress. Some engineers prefer to experiment with blends of these materials to achieve better performance. However, this can complicate the manufacturing process and introduce variability in quality.

Further considerations are the operating conditions of the pump. High temperatures or abrasive fluids can affect the longevity of the impeller. A deeper understanding of the fluid’s characteristics is essential. Often, engineers must balance costs against performance. There is a trade-off between using a cheaper material and ensuring optimal efficiency over time. Proper selection requires careful analysis, which can be a learning experience for many in the field.

What is a Rubber Pump Impeller and How Does It Work? - Materials Used in Rubber Pump Impellers

| Material | Advantages | Common Applications | Temperature Resistance |

|---|---|---|---|

| Natural Rubber (NR) | Excellent elasticity, high abrasion resistance | Water pumps, sewage applications | -30°C to 70°C |

| Nitrile Rubber (NBR) | Good oil resistance, low compression set | Fuel pumps, chemical processing | -20°C to 100°C |

| Ethylene Propylene Diene Monomer (EPDM) | Outstanding weather and ozone resistance | Hot water applications, outdoor equipment | -50°C to 120°C |

| Silicone Rubber | Wide temperature range, excellent flexibility | Food processing, biomedical applications | -60°C to 200°C |

| Neoprene Rubber | Good chemical stability and flexibility | Marine applications, refrigeration | -40°C to 120°C |

Applications of Rubber Pump Impellers in Various Industries

Rubber pump impellers are versatile components used across various industries. In the food and beverage sector, they excel at handling viscous liquids. Their flexibility prevents damage during operation. This ensures a consistent flow, crucial for production efficiency. In wastewater management, rubber impellers can effectively transport abrasive materials. Their ability to withstand harsh conditions enhances their lifespan.

Chemical processing is another key application area. Rubber impellers resist corrosion, making them ideal for transporting aggressive chemicals. This durability reduces maintenance needs. Moreover, in agriculture, these impellers assist in irrigation systems. They help to manage water flow without contaminating it.

Despite their advantages, rubber pump impellers can face challenges. They may swell or degrade with certain fluids. Regular monitoring is essential to ensure optimal performance. Adjustments can help overcome these issues. Balancing flexibility and durability is crucial for their effectiveness. The ongoing development in materials science continues to improve their capabilities.

Maintenance and Longevity of Rubber Pump Impellers

Rubber pump impellers play a crucial role in fluid transfer. They are commonly used in various applications due to their flexibility and durability. However, maintaining these components can be challenging. Regular inspection is essential. Look for signs of wear and tear, such as cracks or deformations. These issues can develop over time. They can reduce efficiency.

Cleaning is another vital aspect of maintenance. Impellers can accumulate debris and residues. This buildup can affect performance. Make sure to use appropriate cleaning agents. Harsh chemicals may damage rubber components. After cleaning, inspect again for any hidden problems. This step helps extend the impeller's lifespan.

Additionally, consider temperature and pressure levels during operation. Excessive conditions can lead to premature failure. Monitoring these factors can prevent unexpected breakdowns. Some users overlook this aspect, leading to costly repairs. Addressing these considerations will maximize the impeller's longevity and effectiveness.