Ultimate Guide to Sourcing the Best CNC Precision Parts: Key Insights and Industry Trends

In the rapidly evolving landscape of manufacturing, the demand for CNC precision parts has surged, driven by advancements in technology and an increasing emphasis on quality and efficiency. According to a report from MarketsandMarkets, the global CNC machining market is projected to reach USD 100 billion by 2023, fueled by the growing need for customized components across various industries, including automotive, aerospace, and electronics. This growth underscores the significance of sourcing high-quality CNC precision parts, as organizations strive to enhance their production capabilities while maintaining competitive pricing.

With China's stronghold in global manufacturing, characterized by world-class capabilities and innovations, businesses can leverage advanced CNC technologies to ensure superior quality and reliability in their products. As we dive into the ultimate guide for sourcing the best CNC precision parts, we will explore key insights and industry trends that are shaping this critical sector, enabling manufacturers to make informed decisions in their procurement strategies.

With China's stronghold in global manufacturing, characterized by world-class capabilities and innovations, businesses can leverage advanced CNC technologies to ensure superior quality and reliability in their products. As we dive into the ultimate guide for sourcing the best CNC precision parts, we will explore key insights and industry trends that are shaping this critical sector, enabling manufacturers to make informed decisions in their procurement strategies.

Essential Criteria for Evaluating CNC Precision Parts Suppliers

When sourcing CNC precision parts, selecting the right supplier is crucial to ensuring optimal quality and performance in your projects. The first essential criterion to evaluate is the supplier's capabilities and experience in the specific materials and processes you require. A supplier with a proven track record in your industry not only understands the nuances of manufacturing precision parts but is also equipped to handle the most demanding specifications. Reviewing their portfolio and asking for case studies can provide valuable insights into their operational strengths.

Another important factor is the supplier's quality control practices. Implementing robust quality assurance procedures is vital to maintaining consistency and accuracy in CNC machining. Look for suppliers who are certified by recognized standards such as ISO 9001, as this signifies a commitment to quality and reliability. Additionally, inquire about their inspection processes, machinery calibration, and employee training programs to ensure they adhere to the highest quality standards throughout their manufacturing process. By focusing on these criteria, you can make an informed decision that will enhance the efficiency and success of your projects.

Ultimate Guide to Sourcing the Best CNC Precision Parts: Key Insights and Industry Trends - Essential Criteria for Evaluating CNC Precision Parts Suppliers

| Supplier Criteria | Importance Level | Evaluation Method | Industry Trend |

|---|---|---|---|

| Quality Assurance | High | ISO Certification Review | Increased emphasis on quality standards. |

| Delivery Time | High | Lead Time Analysis | Growing trend towards just-in-time manufacturing. |

| Cost Efficiency | Medium | Cost Comparison Analysis | Increased competition driving down prices. |

| Supplier Reputation | High | Customer Reviews and Case Studies | Focus on supplier reliability and long-term partnerships. |

| Technological Capability | Medium | Technical Capability Audit | Adoption of advanced machining technologies. |

Top Industry Trends Impacting CNC Sourcing Decisions

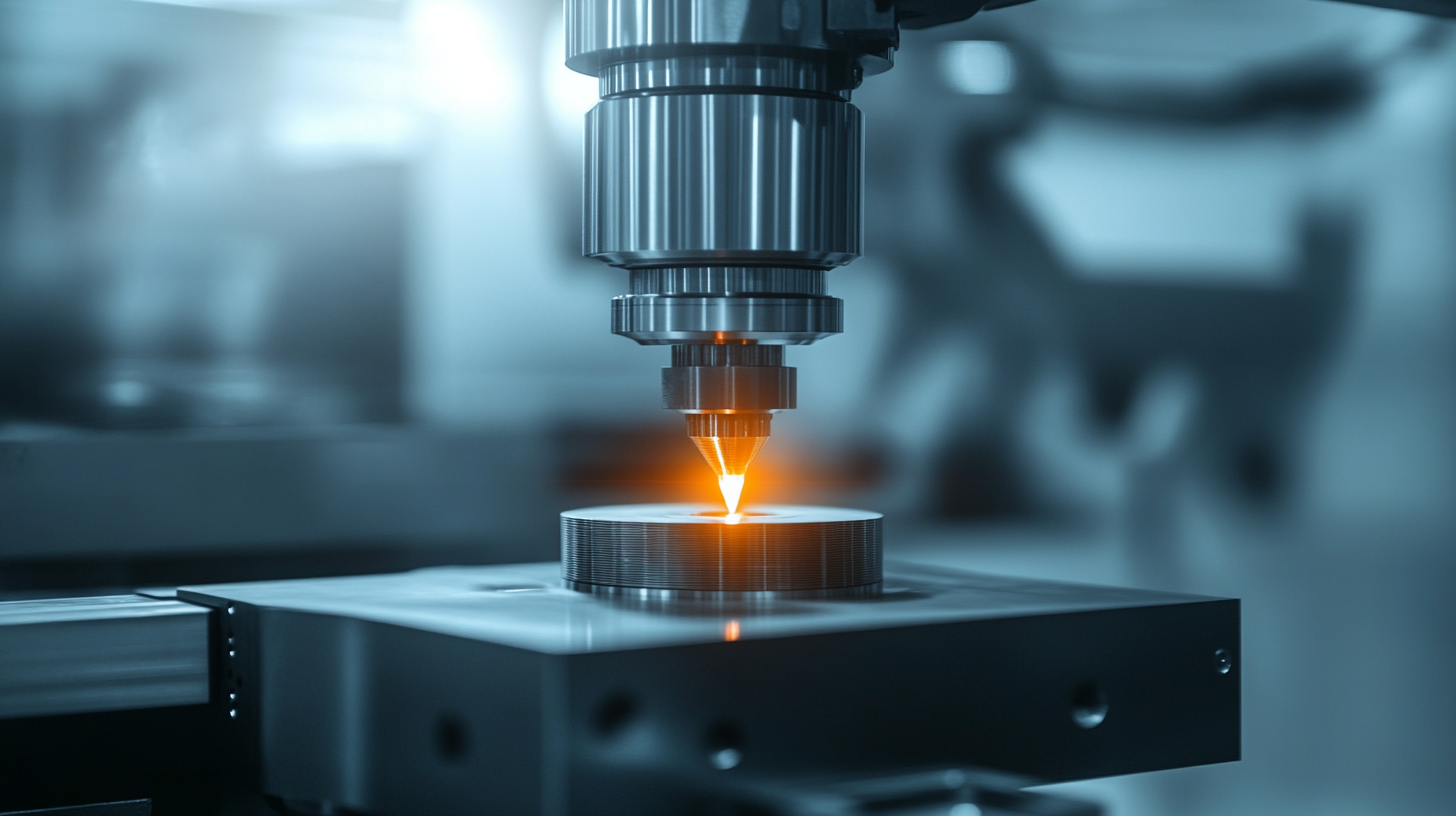

In recent years, the CNC precision parts industry has experienced significant shifts driven by advancements in technology and evolving market demands. One of the most prominent trends is the increasing automation of manufacturing processes. As companies strive for greater efficiency and reduced lead times, integrating automated CNC machines has become essential. This shift not only enhances productivity but also improves precision, allowing manufacturers to meet the high standards required for quality parts.

Another pivotal trend influencing CNC sourcing decisions is the growing emphasis on sustainability. Businesses are increasingly seeking suppliers who prioritize environmentally friendly practices, such as reducing waste and utilizing renewable materials. This shift is not only beneficial for the planet but also resonates with consumers who prefer to support eco-conscious brands. As a result, suppliers that invest in green technologies and sustainable practices are likely to gain a competitive edge in the market.

Moreover, the importance of real-time data analytics in the decision-making process cannot be overlooked. By leveraging data, companies can forecast demand more accurately and optimize their supply chain operations. This trend enables manufacturers to make informed sourcing decisions, ensuring they remain agile in a constantly changing marketplace. As the industry evolves, embracing these trends will be crucial for companies looking to enhance their CNC sourcing strategies and maintain a competitive advantage.

A Comprehensive Checklist for Quality Assurance in CNC Parts

In the world of CNC precision parts manufacturing, ensuring quality is paramount. A comprehensive checklist for quality assurance is essential for manufacturers to meet industry standards and customer expectations. Recent advancements highlight the importance of sophisticated quality assurance equipment. For instance, the integration of new image dimension measurement systems in inspection facilities allows for meticulous analysis and assurance of part specifications. This illustrates how investing in technology can enhance the capability to deliver high-quality components that adhere to stringent requirements.

Another significant trend is the increase in monitoring practices within additive manufacturing. Companies are now focusing on in-situ process monitoring to guarantee part quality, which facilitates the production of complex and customized designs. This proactive approach not only enhances the manufacturing process but also builds trust with customers by ensuring that the parts delivered meet quality benchmarks. As the industry evolves, staying updated on these key insights and leveraging advanced quality assurance tools will be crucial for organizations aiming to remain competitive and reliable in the CNC precision parts landscape.

Comparison of Materials Used in CNC Precision Parts

This chart illustrates the percentage of various materials utilized in the production of CNC precision parts. Aluminum is the most commonly used material, followed by Steel, highlighting the trends and preferences in the industry. Understanding these trends is crucial for sourcing quality CNC parts.

Common Mistakes to Avoid When Sourcing CNC Components

When sourcing CNC components, avoiding common pitfalls can save both time and money. One prevalent mistake is failing to conduct proper research on potential suppliers. Companies often select vendors based solely on price, overlooking their reputation, production capabilities, and quality assurance processes. It’s crucial to evaluate a supplier's track record and seek references to ensure they can meet your specific needs and maintain product consistency over time.

Another frequent error is neglecting to communicate clearly with suppliers. Misunderstandings about specifications, materials, or delivery times can lead to costly delays and production issues. Establishing a comprehensive set of requirements and engaging in open dialogue throughout the sourcing process can help clarify expectations and foster a more productive partnership. Additionally, consider leveraging technology, such as CAD software, to provide clear design specifications, minimizing the chances for errors during manufacturing.

Lastly, many businesses overlook the importance of testing and quality control. Relying solely on first-run components without a thorough inspection can lead to unforeseen failures in the final product. Implementing a robust quality assurance process, including routine checks and audits, will ensure that your CNC components meet the desired standards and performance levels, helping you avoid potential setbacks down the line.

Strategies for Building Long-Term Relationships with CNC Manufacturers

Building long-term relationships with CNC manufacturers is crucial for companies that rely on precision parts for their operations. Establishing trust starts with open and honest communication. Engage with manufacturers to understand their capabilities, production processes, and constraints. Regularly discussing expectations and potential challenges fosters a collaborative environment where both parties can contribute ideas and solutions, ultimately leading to higher quality products.

Beyond communication, it is essential to demonstrate commitment and reliability. This can be achieved by placing consistent orders and respecting payment terms, which reassures manufacturers that you value their partnership. Consider collaborating on projects that allow for shared investment in technology or processes, as this not only enhances production efficiency but also strengthens the bond between companies. Over time, such relationships can lead to preferential treatment, quicker response times, and even collaborative development of new materials or designs that meet unique requirements.