Navigating 2025: The Ultimate Guide to the Best Small CNC Lathe Innovations for Global Buyers

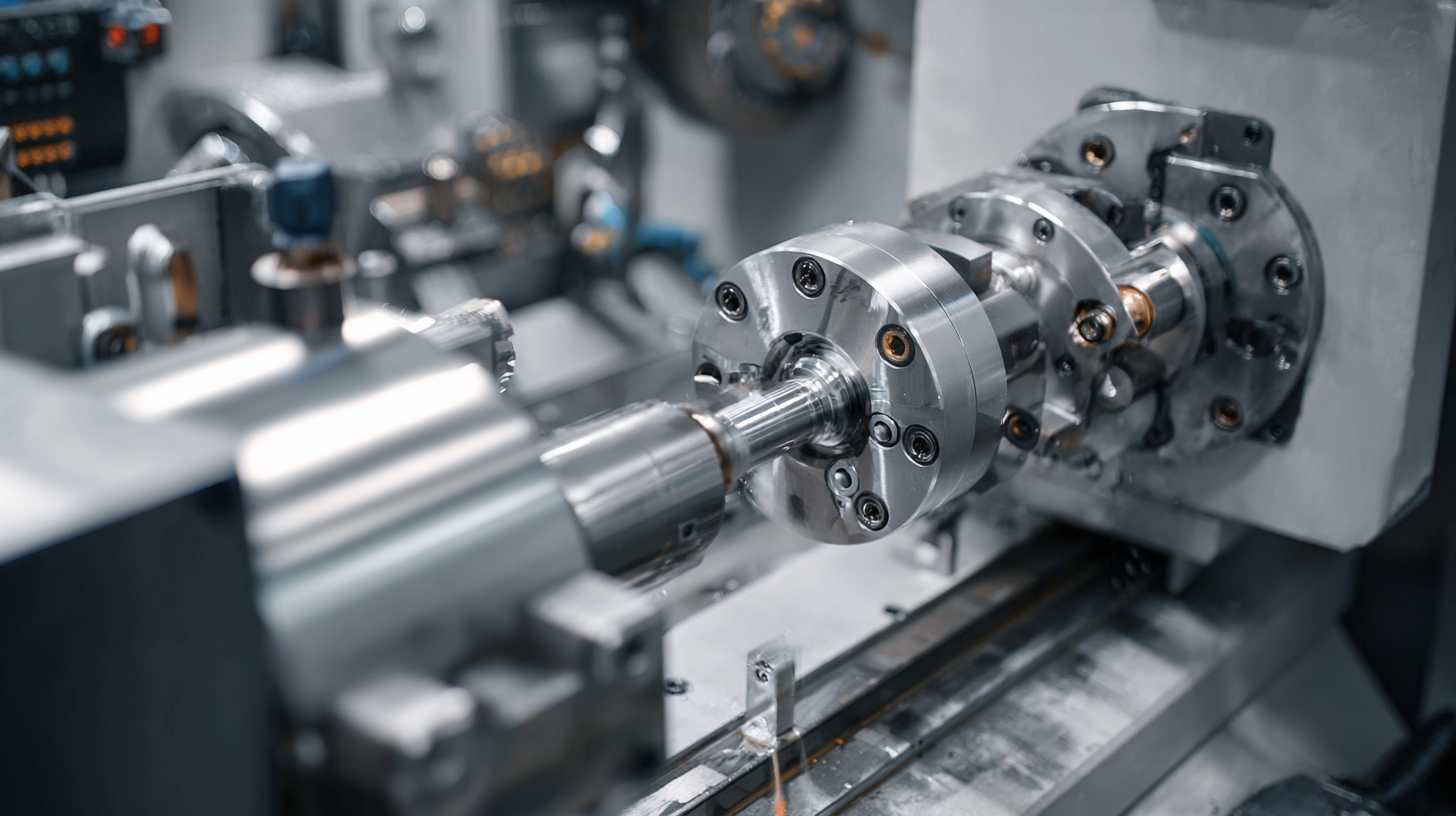

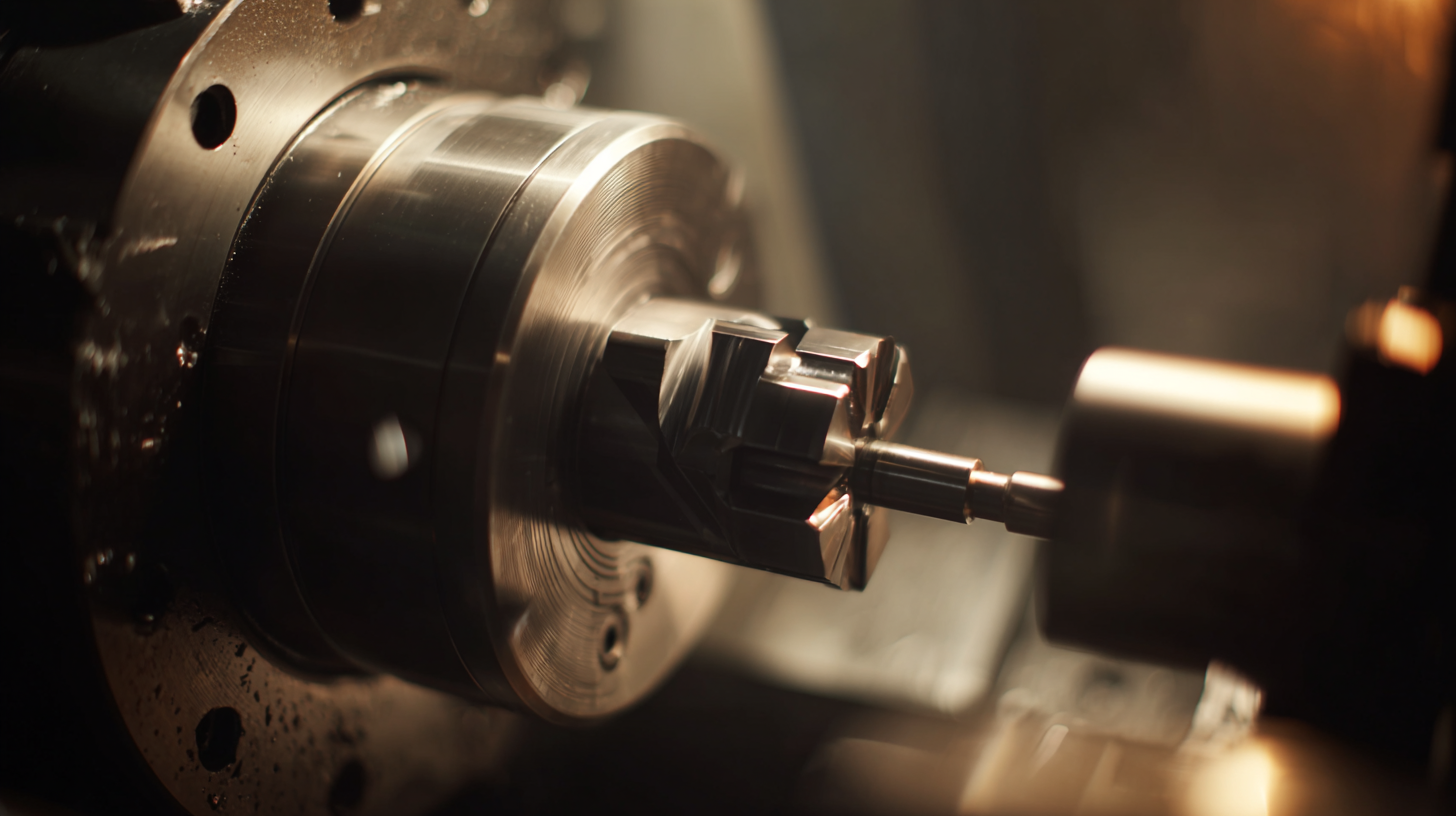

As the manufacturing landscape evolves, the importance of small CNC lathes has surged, making them essential tools for precision engineering and small-scale production. According to a report by the International Federation of Robotics, the adoption of CNC technologies is projected to increase by 14% annually, indicating a strong shift towards automation in machining processes. Small CNC lathes, known for their versatility and efficiency, are at the forefront of this trend, offering manufacturers the ability to craft intricate components with high precision. In 2025, the innovations in this sector promise to revolutionize production capabilities, ensuring that global buyers can meet the rising demand for customized and finely crafted products. This guide aims to navigate the latest advancements, trends, and features in small CNC lathes, providing valuable insights for manufacturers looking to enhance their operational efficiency and competitive edge.

Understanding the Importance of After-Sales Service for Small CNC Lathes

In the rapidly evolving landscape of CNC machinery,

after-sales service has emerged as a pivotal aspect for buyers, particularly in the

small CNC lathe market. According to recent industry reports,

74% of buyers prioritize after-sales support in their purchasing decisions,

underscoring the need for manufacturers to establish robust service frameworks.

This trend is fueled by the increasing complexity of machines and the demand for

uninterrupted production processes, where any downtime can lead to significant

financial losses.

Moreover, research indicates that effective after-sales service can enhance customer satisfaction by 30%, creating a competitive edge for manufacturers. A reliable service infrastructure not only includes timely maintenance and repairs but also access to technical support and spare parts. With the global market for small CNC lathes projected to grow by 5% annually until 2025, companies cannot afford to neglect the importance of after-sales service. By investing in these support systems, manufacturers can ensure a loyal customer base and increased market share, ultimately contributing to long-term success in this competitive industry.

Analyzing Maintenance Costs: What Global Buyers Should Consider

When considering the purchase of a small CNC lathe, global buyers must keenly analyze maintenance costs alongside the initial investment. As manufacturers innovate and enhance the capabilities of small CNC lathes, the long-term operational expenses—especially maintenance—can significantly influence a buyer's decision. It's crucial to evaluate not only the purchase price but also the frequency and costs of necessary repairs, downtime, and the availability of spare parts. Comprehensive research into vendor reputation and service offerings can mitigate unexpected expenses and ensure operational efficiency.

In today's global market, factors like tariffs can also affect pricing and availability of components, further complicating the maintenance landscape. Understanding the financial implications of these external economic pressures is vital. As costs rise due to tariffs, buyers should factor potential increases in maintenance and parts replacement into their total cost of ownership analysis. The strategic foresight in recognizing these elements can lead buyers to make more informed decisions that align with their operational goals and budget constraints.

Innovative Features in Small CNC Lathes That Enhance Serviceability

As small CNC lathes continue to evolve, innovations focused on serviceability and ease of maintenance are pivotal for global buyers. According to a recent industry report by MarketsandMarkets, the global CNC lathe market is projected to reach USD 4.8 billion by 2025, driven largely by advancements in automation and machine intelligence. These advancements are particularly beneficial for small manufacturers who need to maximize uptime and reduce operational costs. Features such as self-diagnosing systems and modular designs allow for quicker repairs, minimizing downtime and increasing machine utilization.

Furthermore, the integration of IoT technology in small CNC lathes is transforming serviceability. Real-time monitoring systems now enable operators to track machine performance and receive alerts for maintenance needs before issues escalate. A study from Statista indicates that connected machines can substantially reduce unexpected breakdowns by up to 30%, ensuring a more efficient production environment. Understanding these innovative features is essential for modern manufacturers looking to navigate the complexities of the 2025 market landscape effectively.

Case Studies: Successful After-Sales Support in the CNC Industry

In the rapidly evolving world of CNC machinery, after-sales support has become a pivotal factor for buyers. As demonstrated in several case studies, companies that prioritize robust after-sales services often outperform competitors. A notable example is a leading CNC lathe manufacturer that implemented a proactive support strategy, including regular maintenance checks and on-site technical assistance. This approach not only ensured optimal machine performance but also fostered strong relationships with clients, enhancing overall satisfaction and loyalty.

Another case study highlights a small CNC lathe provider that introduced an innovative online support platform. By integrating video tutorials and live chat options, they empowered users to troubleshoot minor issues independently, significantly reducing downtime. Feedback from customers indicated that this initiative not only streamlined their operations but also increased their confidence in utilizing the equipment. These examples illustrate that effective after-sales support is not just a supplementary service; it's essential for fostering trust and ensuring that global buyers can maximize the value of their investments in CNC technology.

Another case study highlights a small CNC lathe provider that introduced an innovative online support platform. By integrating video tutorials and live chat options, they empowered users to troubleshoot minor issues independently, significantly reducing downtime. Feedback from customers indicated that this initiative not only streamlined their operations but also increased their confidence in utilizing the equipment. These examples illustrate that effective after-sales support is not just a supplementary service; it's essential for fostering trust and ensuring that global buyers can maximize the value of their investments in CNC technology.

Comparative Analysis: Repair Costs Across Different Small CNC Lathe Models

In the rapidly evolving world of small CNC lathes, understanding repair costs across different models is crucial for global buyers. A recent analysis of maintenance expenditures indicates that operational efficiency and cost management play significant roles in the long-term viability of these machines. For instance, a manufacturer highlighted the stark contrast in total operational costs when comparing models with advanced hydraulic systems versus traditional setups. Notably, machines with integrated maintenance features yield lower repair bills, offering a more sustainable investment for users.

Tips: When selecting a small CNC lathe, consider models with proactive maintenance alerts and user-friendly diagnostic tools. Not only do these features reduce downtime, but they also ensure that maintenance costs remain manageable. Furthermore, reviewing comprehensive cost reports from multiple sources will provide a clearer picture of potential long-term expenses.

Moreover, data from industry research indicates that manufacturers who adopt modern upkeep strategies can reduce their operational costs by up to 25%. This statistic underscores the importance of technology integration in machinery. Comparative analyses enable buyers to pinpoint the models that not only meet their machining needs but also align with their financial strategies, fostering smarter buying decisions in a competitive market.