Ultimate Guide to Your Best Small Cnc Lathe Purchase Checklist

When it comes to precision machining, investing in a Small CNC Lathe can significantly enhance your productivity and accuracy. These versatile machines are designed to handle a wide range of materials and applications, making them an ideal choice for both hobbyists and professionals in various industries. In this ultimate guide, we will explore the essential features and benefits of different types of small CNC lathes, helping you understand which model best suits your specific needs. From intricate jewelry making to robust component manufacturing, the right Small CNC Lathe can empower you to take your projects to the next level. Join us as we delve into the critical factors to consider in your purchasing checklist and unlock the full potential of your machining capabilities.

Factors to Consider When Choosing a Small CNC Lathe

When choosing a small CNC lathe, several critical factors must be taken into consideration to ensure you make the right investment. First and foremost, the size and weight of the machine are crucial. According to a recent report by the Association for Manufacturing Technology (AMT), smaller CNC lathes typically range from 300 to 800 lbs, making them portable yet sturdy enough for precision machining. Buyers should evaluate their workspace and consider whether the lathe can fit comfortably without sacrificing essential workflow.

Moreover, the machine's capabilities regarding spindle speed and power play a significant role in its performance. A research study by Grand View Research indicates that lathes with spindle speeds exceeding 3,000 RPM provide better efficiency for a variety of materials, particularly in producing intricate designs. Additionally, it’s vital to assess the available tooling options and the ease of integration with existing software, as these factors can significantly influence setup time and operational costs. Investing time in evaluating these elements will lead to a more informed purchase that meets your specific machining needs.

Ultimate Guide to Your Best Small CNC Lathe Purchase Checklist - Factors to Consider When Choosing a Small CNC Lathe

| Feature | Description | Importance Level |

|---|---|---|

| Size | The physical dimensions of the lathe that fit your workspace. | High |

| Spindle Speed | The maximum rotational speed of the spindle. | High |

| Tool Capacity | Number of tools that can be loaded simultaneously. | Medium |

| Material Compatibility | Types of materials the lathe can process (e.g., metal, plastic). | High |

| Control Software | Type of software used to operate the CNC lathe. | Medium |

| Price Range | Cost of the CNC lathe, which may vary widely. | High |

| Warranty | Length and coverage of the manufacturer's warranty. | Medium |

| Support and Service | Availability of customer support and service. | Medium |

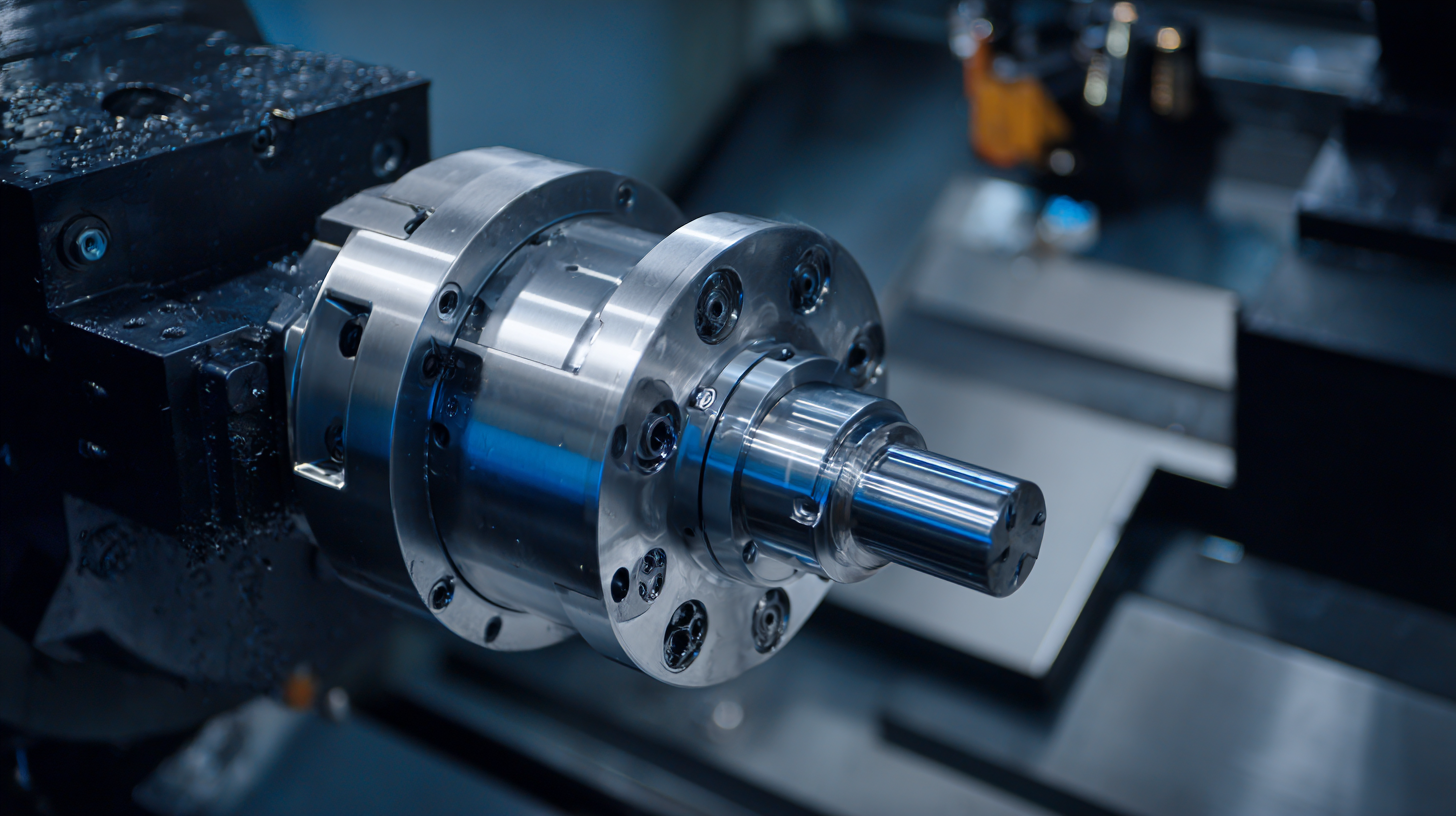

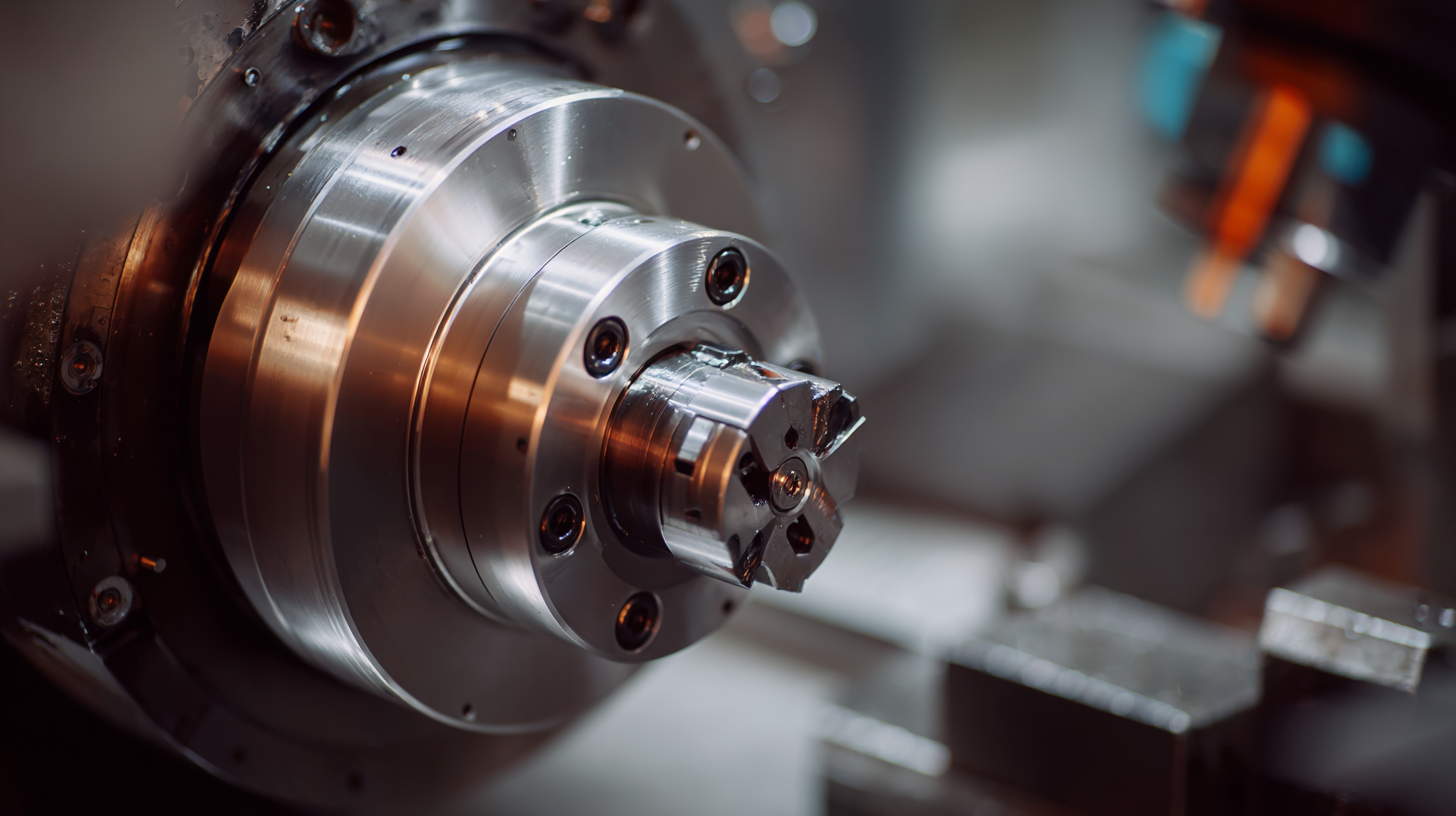

Essential Features for Efficient Machining on Small CNC Lathes

When considering the purchase of a small CNC lathe, focusing on essential features is critical for efficient machining. Key specifications include spindle speed, torque, and the machine's overall rigidity. According to a report by the International Federation of Robotics, the demand for compact CNC machines has surged by over 25% in the past five years. This trend highlights the importance of robust and versatile machinery that can handle various materials while delivering accuracy and precision.

One vital feature is the control system. A user-friendly interface with advanced CNC programming capabilities can significantly enhance productivity. Look for machines equipped with a robust software package, allowing for simplified design modifications and real-time monitoring. It's advisable to opt for CNC lathes that offer seamless integration with CAD/CAM software, a feature noted to improve operational efficiency by up to 30%, based on findings by the American Society of Mechanical Engineers.

Tips: Always evaluate the availability of replacement parts and customer support services for the CNC lathe you consider. Additionally, prioritize machines with high torque at low speeds for better material handling, ensuring they can work with a variety of metals and alloys effectively. Investing time in selecting the right specifications will lead to improved outcomes in your machining projects.

Top Brands of Small CNC Lathes for Quality and Reliability

When it comes to selecting a small CNC lathe, quality and reliability are paramount. Many enthusiasts and professionals turn to established brands that have consistently demonstrated excellence in machining technology. Leading manufacturers such as Haas, Tormach, and Syil are recognized for producing lathes with robust construction and reliable performance. These brands incorporate advanced features such as precision ball screws and quality spindle bearings, ensuring that users can achieve exceptional accuracy in their projects.

In addition to the traditional giants, newer entrants like Genmitsu and SainSmart have gained traction due to their affordable yet efficient small CNC lathes. These brands cater to hobbyists and small businesses seeking high-quality machines without a significant financial investment. Their lathes often come equipped with intuitive software and user-friendly interfaces, making them accessible for beginners while still meeting the demands of experienced machinists. Choosing a reputable brand not only guarantees a better overall user experience but also provides peace of mind regarding customer support and the availability of replacement parts.

Tips for Evaluating CNC Lathe Suppliers in the Global Market

When considering the purchase of a small CNC lathe, evaluating potential suppliers is crucial in the global market. Start by assessing their reputation; look for customer testimonials and industry reviews. A reliable supplier will have a proven track record and positive feedback from other users. Additionally, ensure that the supplier offers comprehensive support services, including training and technical assistance, which can be invaluable as you integrate the new machinery into your operations.

Another essential tip is to investigate the supplier's manufacturing capabilities and quality assurance processes. Suppliers that adhere to international quality standards are more likely to provide a consistent and reliable product. It's also beneficial to request samples or demonstrations, as this allows you to gauge the performance and precision of their CNC lathes firsthand. Lastly, consider the supplier's flexibility in terms of customization options, which can help you tailor the equipment to better meet your specific production needs.

Maintenance Best Practices to Extend the Life of Your CNC Lathe

Regular maintenance is crucial for extending the life of your CNC lathe and ensuring optimal performance. According to a report from the National Institute of Standards and Technology, well-maintained CNC machines can increase productivity by up to 30%. This underscores the importance of adhering to best practices for upkeep. Start with routine inspections of key components like the spindle, tool holders, and coolant systems. Keep these areas clean and properly lubricated to prevent premature wear and tear.

One effective tip is to perform daily checks on temperature and vibration levels. A study by the Manufacturing Technology Association found that machines running at optimal temperatures have a 15% longer lifespan. In addition to daily checks, consider implementing a monthly maintenance schedule that includes deep cleaning and replacement of worn parts. This proactive approach not only enhances performance but also reduces unexpected downtimes.

Lastly, always keep an eye on the software used to operate your CNC lathe. Regular software updates can lead to better machine performance and enhanced functionalities. A report by the Association of Manufacturing Technology highlights that updated software can reduce programming errors by approximately 25%, ultimately saving both time and resources. Prioritizing these best practices will ensure your CNC lathe remains efficient and reliable for years to come.