Exploring the Versatile Features and Applications of the Best CNC Machines for Global Buyers

In today's rapidly evolving manufacturing landscape, the demand for precision and efficiency has led to a significant rise in the adoption of CNC (Computer Numerical Control) machines across various industries. According to a recent market analysis by MarketsandMarkets, the global CNC machine market is expected to reach USD 100 billion by 2027, growing at a CAGR of 6.5% from 2022.

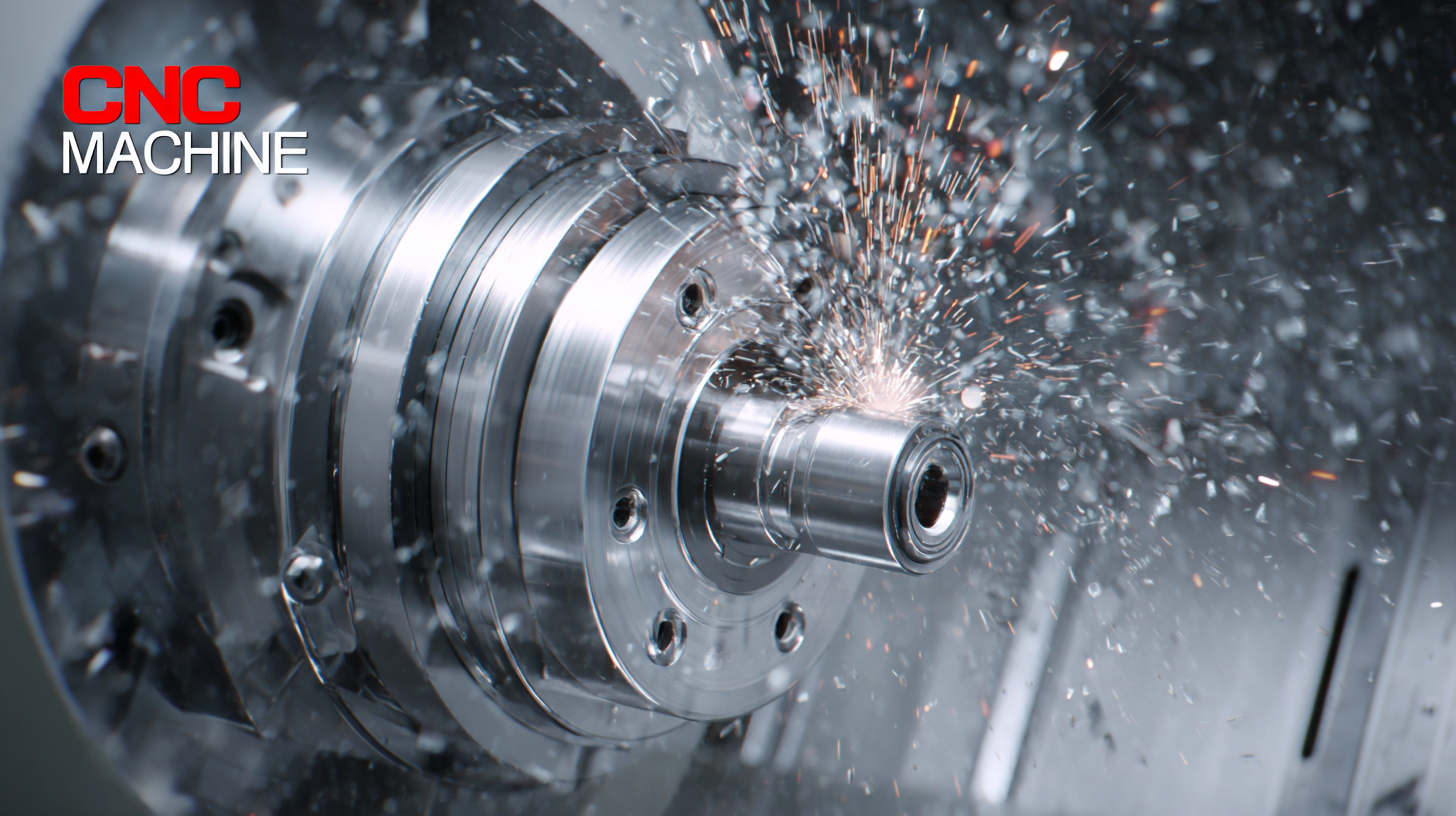

This surge in popularity can be attributed to the versatility of CNC machines, which enable complex machining processes with minimal manual intervention, thereby enhancing productivity and accuracy. Understanding CNC machine working is pivotal for global buyers who seek to leverage these advanced technologies for their operations.

As manufacturers increasingly look to automate their processes and improve output quality, exploring the diverse features and applications of the best CNC machines has become essential for staying competitive in the market.

Understanding CNC Machine Types: Which One Suits Your Needs?

As the demand for precision and efficiency rises across various industries, understanding the types of CNC machines becomes crucial for global buyers. The global CNC machine market is expected to grow significantly, with projections suggesting an increase from $101.22 billion in 2025 to $195.59 billion by 2032, reflecting a compound annual growth rate (CAGR) of 9.9%. This growth is largely driven by advancements in manufacturing technologies and the increasing adoption of automation processes.

Different types of CNC machines cater to various applications, such as laser cutting, drilling, and milling. Within this landscape, laser processing equipment is particularly noteworthy. The market is anticipated to grow due to rising demand in sectors such as oil and gas, automotive, and aerospace, primarily for their drilling applications which require high precision and efficiency.

Reports indicate that the deep hole drilling machine segment alone is projected to exceed $7.69 billion in 2023 and reach $11 billion by 2032, underscoring the importance of selecting the right CNC machinery to meet specific operational needs.

Key Features to Look for in Top CNC Machines for Global Buyers

When considering the purchase of a CNC machine, global buyers should focus on several key features that can significantly affect their operations. First and foremost, the size and capacity of the CNC machine are crucial. Depending on the intended applications—be it woodworking, metalworking, or prototyping—buyers need to select a machine that can accommodate their specific material sizes and production needs. Additionally, the precision and accuracy of the machine play a vital role in ensuring high-quality outputs, which is essential for competitive manufacturing.

Another important feature to consider is the level of automation and smart technology integrated into the CNC machine. As the industry trends towards automation and efficiency, machines equipped with advanced features such as digital twin technology and full-scale automation can provide significant advantages. These machines not only enhance production speed but also reduce error rates, thus improving overall productivity. Buyers should also evaluate the support and service provided by manufacturers, as well as the machine's adaptability to future technological advancements, ensuring their investment remains relevant in a rapidly evolving market.

Exploring the Versatile Features and Applications of the Best CNC Machines for Global Buyers

| Feature | Description | Application |

|---|---|---|

| Precision | High accuracy levels, often within 0.01 mm. | Aerospace, automotive, and medical device manufacturing. |

| Material Versatility | Capability to work with metals, plastics, and composites. | Manufacturing of various components across industries. |

| Automation | Integration with robotics and automated tool changers. | Mass production and efficient manufacturing processes. |

| User Interface | Intuitive control systems and software for ease of use. | User-friendly operation for machine operators and engineers. |

| Size and Footprint | Variety of sizes from compact desktop models to large industrial machines. | Suitable for small workshops to large factories. |

| Support and Training | Availability of technical support and user training programs. | Maximizing machine potential and operator efficiency. |

Exploring Industrial Applications of CNC Machines Across Various Sectors

CNC (Computer Numerical Control) machines have become indispensable in various industrial sectors, transforming the way manufacturing processes are executed. From automatic drilling machines to lathes and milling machines, these technologies are programmed for repetitive tasks, significantly enhancing production efficiency and precision. As industries progress into the era of Industry 4.0, the capabilities of CNC machines are expanding, integrating advanced technologies such as AI and digital twin applications. This evolution not only supports sustainable manufacturing practices but also adapts to the demands of smart production environments.

However, with the increased reliance on CNC machines comes a serious concern regarding cybersecurity threats. Organizations utilizing these machines face risks as they become critical assets in a digitally connected landscape. Recent assessments highlight vulnerabilities within prominent CNC controllers, emphasizing the need for robust cybersecurity measures across the manufacturing sector. The trend of digitization in CNC technology necessitates a proactive approach to safeguard operational integrity while embracing innovations that drive growth. Understanding these applications and their associated risks is essential for global buyers navigating the complex landscape of modern manufacturing.

How to Optimize Your CNC Machining Process for Better Efficiency

Optimizing your CNC machining process is essential for enhancing efficiency and productivity. One critical step is to ensure that your machine is properly calibrated and maintained. Regular maintenance not only extends the lifespan of the equipment but also minimizes errors that can lead to waste. Additionally, leveraging advanced software for toolpath optimization can significantly reduce cycle times. Technologies such as CAD/CAM integration allow for precise planning and execution, making sure that each cut is calculated for maximum efficiency.

Another aspect to consider is the selection of the right materials and tools. Using high-quality materials tailored to the specific CNC machine can improve the final product's quality while reducing wear and tear on the tools. Implementing automation solutions, such as robotic arms or conveyor systems, can also streamline workflows, allowing for continuous operation and reduced downtime. Keep an eye on industry benchmarks and invest in training for your operators to ensure they are equipped with the latest techniques in CNC machining. By focusing on these areas, manufacturers can not only optimize their processes but also achieve a more competitive edge in the global market.

Tips for Choosing the Right CNC Machine Provider for Your Business

When selecting the right CNC machine provider for your business, it is essential to understand your specific needs and how different machines can serve those requirements. The current CNC landscape is evolving, especially within engine shops, which highlights the demand for versatile and efficient machinery. As you explore potential providers, consider their range of offerings, including new technologies and integrations that can enhance your production capabilities.

Here are some tips for choosing the right CNC machine provider: first, evaluate their experience and customer feedback to gauge their reliability. Look for companies that offer comprehensive support services, such as training and maintenance, which can significantly impact your operational efficiency. Also, ensure that the provider can guide you in selecting the best CNC machine that aligns with your production goals.

Additionally, as social media continues to play a pivotal role in the marketing sphere, keep an eye on the online presence of potential providers. This will give you insights into their customer engagement practices and overall brand reliability. By diligently assessing these aspects, you will be better positioned to choose a CNC machine provider that meets your business needs effectively.