Top 10 Multi Axis CNC Machines for Precision Engineering in 2023

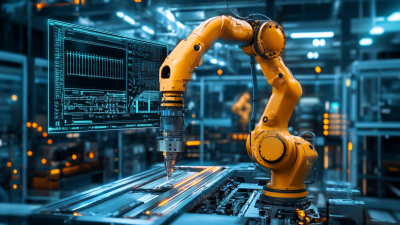

In the fast-evolving landscape of precision engineering, the advent of Multi Axis CNC Machines has revolutionized manufacturing processes across various industries. As engineering demands continue to escalate, the need for advanced machinery that can deliver exceptional accuracy and efficiency has become paramount. Multi Axis CNC Machines stand at the forefront of this technological shift, providing enhanced capabilities that allow for complex geometries and intricate designs to be produced with unparalleled precision.

As we delve into the realm of multi-axis technology, it is essential to recognize how these machines integrate multiple cutting axes, enabling them to execute tasks that traditional CNC machines cannot efficiently handle. This versatility not only streamlines operations but also reduces the time required for setup and machining, ultimately leading to significant cost savings and increased productivity.

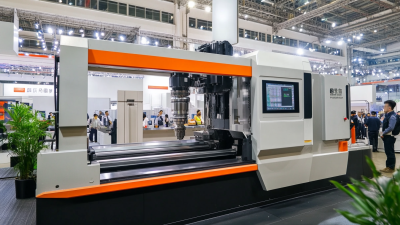

In this article, we will explore the top 10 Multi Axis CNC Machines that are shaping the future of precision engineering in 2023. By examining their features, capabilities, and applications, we aim to provide valuable insights for manufacturers and engineers seeking to enhance their operational efficiency and maintain a competitive edge in the evolving market.

Overview of Multi Axis CNC Machines and Their Importance in Engineering

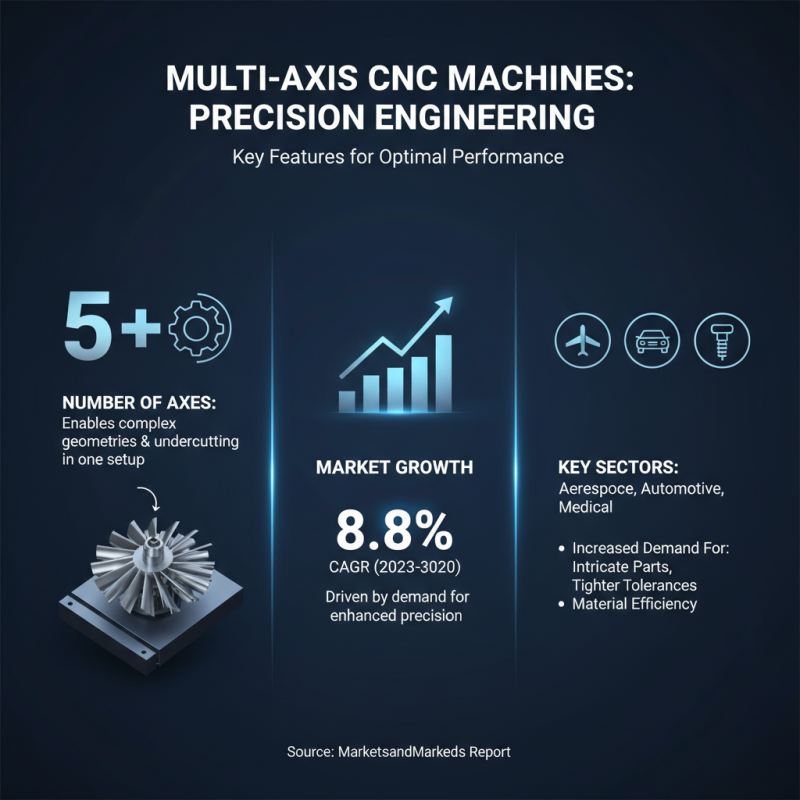

Multi-axis CNC machines play a critical role in precision engineering, delivering capabilities that significantly enhance the manufacturing process. According to a report by MarketsandMarkets, the CNC machine market is projected to reach $117 billion by 2026, driven by the increasing demand for complex geometries and higher efficiency in production cycles. Multi-axis machines, capable of operating along several axes simultaneously, offer unparalleled flexibility and accuracy that traditional machines cannot achieve. This advancement is essential in sectors such as aerospace, automotive, and medical devices, where intricate designs and tight tolerances are paramount.

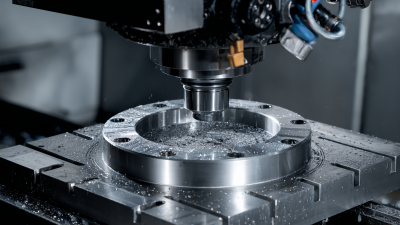

The importance of multi-axis CNC machines is underscored by their ability to perform multiple operations in a single setup, reducing potential errors associated with repositioning workpieces. A study conducted by the National Institute of Standards and Technology (NIST) found that utilizing multi-axis machining can lead to a 30% reduction in production time, while also improving dimensional accuracy by up to 50%. These benefits not only lower manufacturing costs but also facilitate faster time-to-market for innovative engineering solutions. As industries continue to evolve, the adoption of multi-axis CNC technology will be a cornerstone in achieving competitive advantages through enhanced precision and efficiency.

Key Features to Consider When Selecting a Multi Axis CNC Machine

When selecting a multi-axis CNC machine for precision engineering, key features become crucial in ensuring optimal performance and versatility. One of the primary considerations is the number of axes available; machines with five or more axes can perform complex machining tasks that are increasingly demanded in modern manufacturing. According to a report by MarketsandMarkets, the multi-axis CNC machining market is projected to grow at a CAGR of 8.8%, reflecting the rising need for enhanced precision in various sectors, including aerospace, automotive, and medical.

Another vital feature to consider is the machine’s rigidity and thermal stability. These factors significantly influence machining accuracy over extended production runs. Data from a study published in the International Journal of Advanced Manufacturing Technology highlights that improved machine rigidity can lead to a reduction in operational vibrations, resulting in tolerances as tight as ±0.01 mm. Furthermore, the inclusion of advanced software for programming and simulation plays a critical role; it enables operators to visualize machining processes and optimize toolpaths, thus enhancing the overall efficiency and output quality of the production.

Lastly, automation capabilities and compatibility with Industry 4.0 should not be overlooked. Multi-axis CNC machines equipped with smart features, such as predictive maintenance and real-time monitoring, can minimize downtime and enhance productivity. An analysis by Deloitte indicates that manufacturers harnessing automation can witness efficiency gains of up to 20%. With such advancements, selecting the right multi-axis CNC machine becomes pivotal for businesses aiming to uphold competitive advantage in the market.

Top 10 Multi Axis CNC Machines for Precision Engineering in 2023

In the realm of precision engineering, multi-axis CNC machines have revolutionized manufacturing processes, allowing for greater complexity and accuracy in machined parts. Recent industry reports project that the multi-axis CNC machine market is set to grow at a compound annual growth rate (CAGR) of approximately 7.5% through 2028, driven by advancements in technology and increasing demand from sectors such as aerospace, automotive, and medical devices. These machines enhance not only productivity but also the capability to produce intricate geometries that traditional machining techniques struggle to achieve.

According to a comprehensive study by Research and Markets, the rise in the adoption of automation and smart manufacturing practices is a significant factor fueling this growth. Multi-axis CNC machines, which can operate on up to five different axes simultaneously, contribute significantly to reducing cycle times and material waste. They enable engineers to design parts with tighter tolerances and complex features, ultimately leading to higher-quality output. With industries continuously striving for improved efficiency and precision, investing in advanced multi-axis CNC technology is increasingly seen as essential for maintaining a competitive edge in precision engineering.

Comparative Analysis of Multi Axis CNC Machines: Performance and Price

When considering multi-axis CNC machines for precision engineering in 2023, a comparative analysis of their performance and price is crucial. Multi-axis machines offer enhanced capabilities, allowing for intricate designs and complex components to be manufactured with exceptional accuracy. The key factors influencing performance include the number of axes, the machine's rigidity, and the quality of the control software. Additionally, one must assess the speed and feed rates, as these directly impact production efficiency.

When evaluating prices, it's essential to weigh the initial investment against the long-term cost of ownership. Higher-priced machines may offer advanced features and better reliability, potentially resulting in reduced downtime and maintenance costs. Conversely, more affordable options may suffice for simpler tasks but could limit capabilities as project requirements evolve. Therefore, potential buyers should analyze their specific needs and consider future scalability when making a decision.

**Tips:** Consider investing in training programs for your team to maximize the capabilities of advanced multi-axis machines. Additionally, regular maintenance checks can prolong the life of the machinery and ensure peak performance. Lastly, don’t overlook the importance of software compatibility, as the right software can significantly enhance machining efficiency and precision.

Future Trends in Multi Axis CNC Technology and Precision Engineering

The landscape of multi-axis CNC technology is evolving rapidly, driven by advancements in precision engineering and automation. In 2023, we are witnessing an increased integration of artificial intelligence and machine learning into CNC machines, enhancing their capabilities to not only perform complex tasks with unparalleled accuracy but also optimize machining processes in real-time. As engineers seek to meet the growing demand for intricate designs and high-quality finishes, the trend toward multi-axis machining is increasingly favored for its ability to reduce setup times and the number of fixtures required.

Tips for selecting the right multi-axis CNC machine for your needs include assessing the types of materials you will primarily work with and understanding the specific applications required for your production. It’s essential to consider machines that offer greater flexibility in tool paths and the ability to program intricate designs without compromising on precision. Moreover, keeping abreast of emerging technologies such as 3D printing integration with multi-axis machining can enhance overall production efficiency and open new possibilities for design innovation.

Furthermore, the future of multi-axis CNC technology lies in connectivity and smart manufacturing. Machines equipped with IoT capabilities can collect data to predict maintenance needs and improve workflow, thus ensuring minimal downtime. Emphasizing this trend, engineers and manufacturers should look for systems that not only enhance operational efficiency but also foster a culture of continuous improvement through data-driven insights.

Top 10 Multi Axis CNC Machines for Precision Engineering in 2023

| Machine Model | Axis Count | Max Tool Diameter (mm) | Spindle Speed (RPM) | Control System | Price Range (USD) |

|---|---|---|---|---|---|

| Model A | 5 | 25 | 12000 | Fanuc | $80,000 - $120,000 |

| Model B | 6 | 30 | 10000 | Siemens | $90,000 - $150,000 |

| Model C | 7 | 28 | 15000 | Heidenhain | $110,000 - $180,000 |

| Model D | 5 | 26 | 12000 | Mitsubishi | $70,000 - $115,000 |

| Model E | 5 | 24 | 9000 | Okuma | $60,000 - $100,000 |

| Model F | 8 | 22 | 14000 | Yaskawa | $130,000 - $200,000 |

| Model G | 5 | 20 | 11000 | Parameter | $75,000 - $125,000 |

| Model H | 6 | 25 | 13000 | Fagor | $85,000 - $140,000 |

| Model I | 7 | 29 | 15000 | MCC | $200,000 - $300,000 |

| Model J | 5 | 26 | 10000 | Fadal | $50,000 - $90,000 |

Related Posts

-

Exploring Opportunities for Multi Axis CNC Machine at the Successful 137th China Import and Export Fair

-

How to Maximize Efficiency with a Multi Axis CNC Machine for Your Projects

-

Understanding Manufacturing Standards for the Best Desktop CNC Milling Machine for Global Buyers

-

Transforming Manufacturing: 2025 Innovations in CNC Turning Machines & Buyer’s Guide

-

Innovative Approaches to Sourcing the Best Desktop Cnc Milling Machine Worldwide

-

What is Cnc Machining Parts and How They Transform Modern Manufacturing